Quenching cooling monitoring system

A monitoring system and control system technology, which is applied in heat treatment process control, heat treatment equipment, manufacturing tools, etc., can solve problems such as defective products, economic losses, and wear of cooling motors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

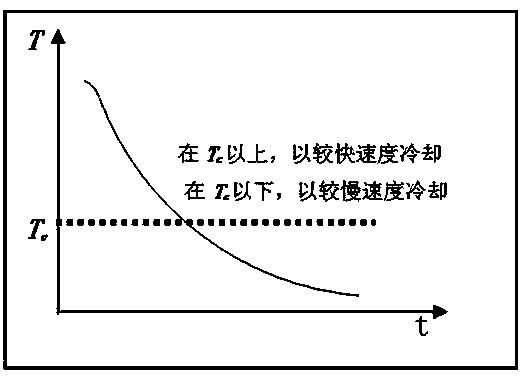

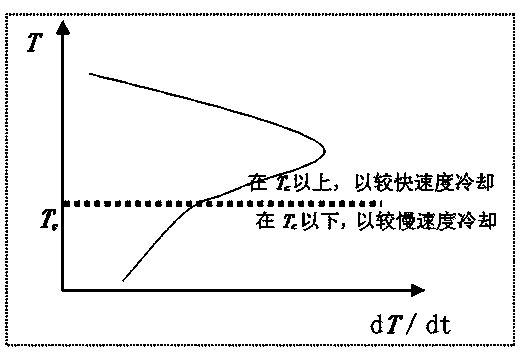

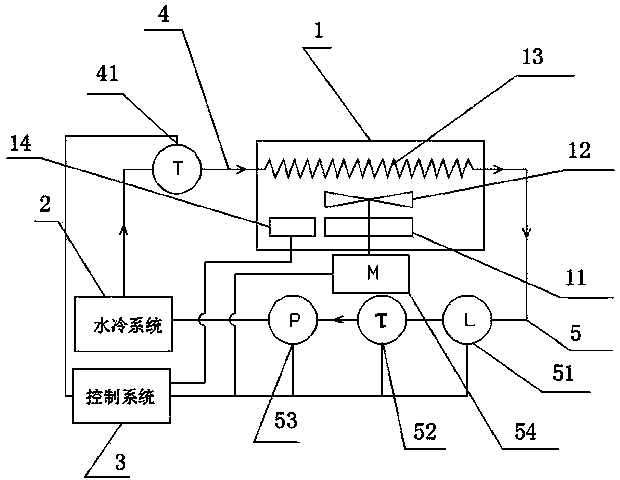

[0053] In this embodiment, refer to image 3 As shown, the quenching cooling monitoring system includes a water cooling system 2, a heat exchange system 1 and a control system 3, as well as a cold conveying pipe 4 and a heat conveying pipe 5 arranged in a clockwise layout between the water cooling system 2 and the heat exchange system 1, And the cold end thermometer 41 arranged on the cold conveying pipe 4 for detecting the temperature of the cooling liquid, and the flow meter 51, the hot end thermometer 52 and the water pump 53 arranged in a clockwise layout on the hot conveying pipe 5; the described The heat exchange system 1 is provided with an air pressure gauge 14, a convection fan blade 12 and a heat exchanger 13. The convection fan blade 12 blows the air flow to blow the heat on the workpiece 11 to the heat exchanger 13, and the cooling liquid pushes the heat exchanger 13. The heat is absorbed and taken away; the heat exchange system 1 is provided with a convection fan ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com