Position determining method for postweld heat treatment temperature equivalent points of inner walls of steel pipes with 9 percent of Cr

A technology for post-weld heat treatment and determination of methods, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve problems such as increased cost, wasted time, and experimental results do not have universal applicability, etc., to increase costs, facilitate monitoring, and ensure heat treatment. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solution of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

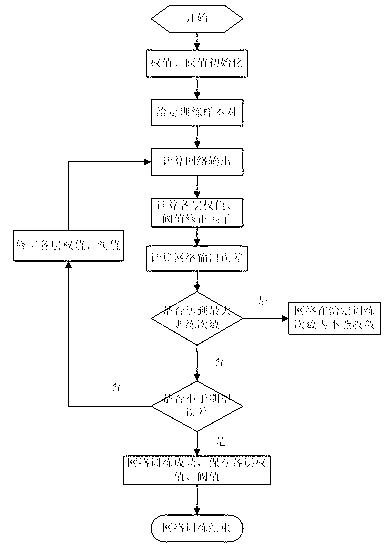

[0038] The method for determining the position of the temperature equivalent point of the inner wall of the post-weld heat treatment of the 9% Cr steel pipeline of the present invention comprises the following steps.

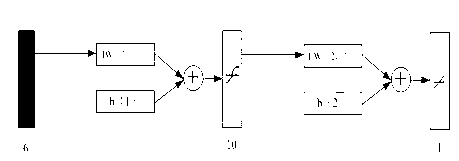

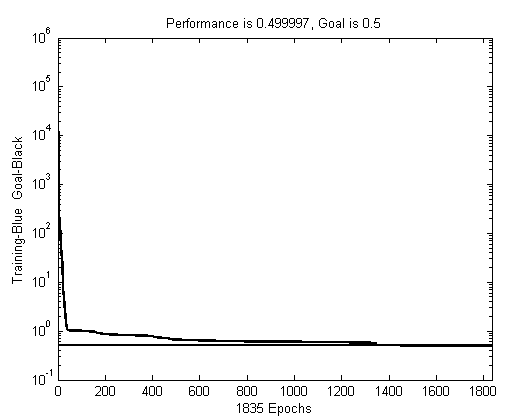

[0039] Step 1, the theoretical calculation module of the equivalent point position. In this module, based on the theory of heat transfer, the calculation model of the heat temperature field of the upper T group of pipes with different sizes under different heating widths, different insulation widths, different heat treatment ambient temperatures, and different temperature control temperatures is established, and the calculation models of each group are calculated. The location of the temperature equivalent point of the inner wall after post-weld heat treatment, the specific method is:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com