Polymer group composite material self-repairing nano-scale capsule and preparation method thereof

A composite material and self-healing technology, applied in the directions of microcapsule preparation, microsphere preparation, etc., can solve the problems of reducing the mechanical properties of polymer-based composite materials, large size, shortening service life, etc., and achieves low equipment performance requirements and preparation methods. Simple, improve the effect of bonding problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

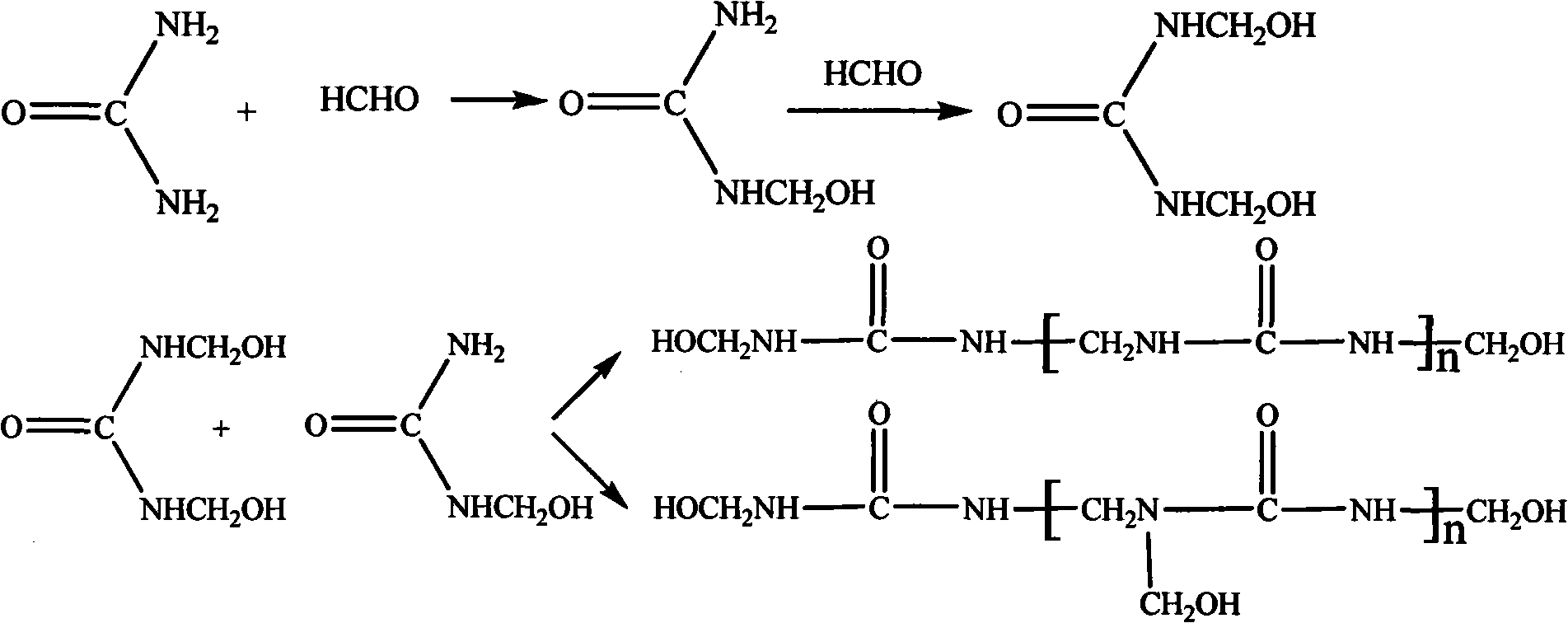

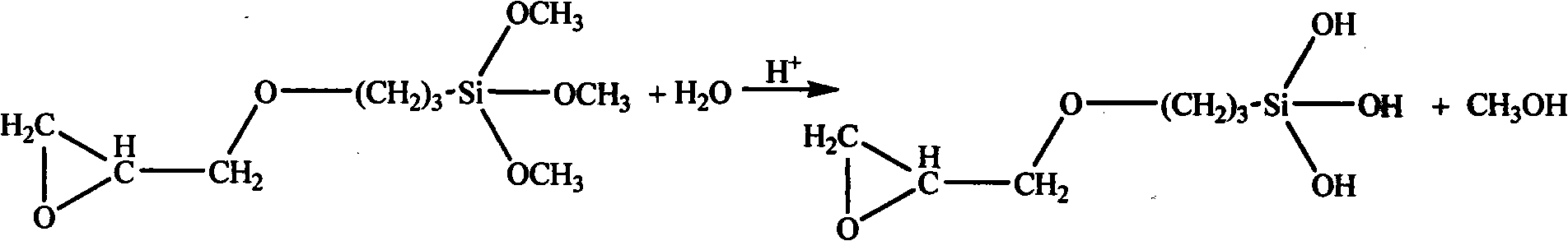

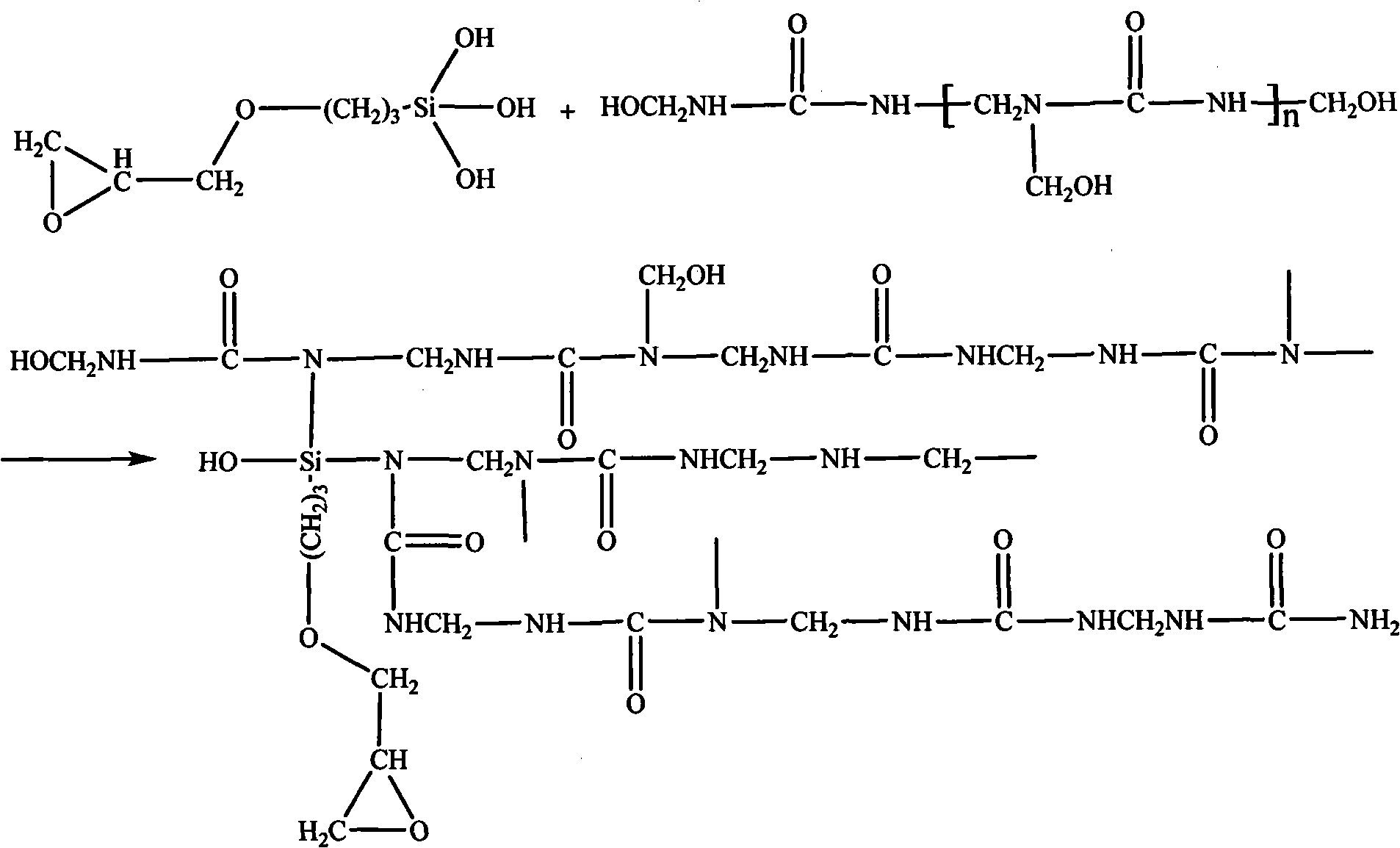

Method used

Image

Examples

specific Embodiment approach 1

[0011] Specific Embodiment 1: In this embodiment, the self-healing nano-scale capsules of polymer-based composite materials are composed of 10-100 parts by weight of urea, 10-200 parts of formaldehyde solution, 10-400 parts of dicyclopentadiene, and 0.03-10 parts Sodium dodecylbenzenesulfonate, 0.5-10 parts of resorcinol, 0.01-10 parts of n-butanol, 0.01-10 parts of octane, 5-50 parts of (3,2-epoxypropoxy) propyl It is made of trimethoxysilane and 30-600 parts of deionized water, and the pH value is adjusted with triethanolamine and glacial acetic acid solution.

[0012] In this embodiment, the self-healing nanoscale capsules of the polymer-based composite material can be used to repair tiny cracks with a crack size of 100-800nm, which can self-heal cracks as early as possible, prevent the spread and expansion of cracks, and reduce the damage caused by cracks in the polymer matrix. Composite mechanical properties are lost and can prolong the service life of polymer matrix comp...

specific Embodiment approach 2

[0013] Specific embodiment two: The difference between this embodiment and specific embodiment one is: the self-healing nano-capsules of polymer-based composite materials are composed of 20-80 parts of urea, 20-180 parts of formaldehyde solution, 20-350 parts of Parts of dicyclopentadiene, 0.1 to 8 parts of sodium dodecylbenzenesulfonate, 1 to 8 parts of resorcinol, 0.1 to 8 parts of n-butanol, 0.1 to 8 parts of octane, 10 to 45 parts (3, 2-glycidoxy) propyltrimethoxysilane and 30 to 600 parts of deionized water. Others are the same as the first embodiment.

specific Embodiment approach 3

[0014] Specific embodiment three: The difference between this embodiment and specific embodiment one is: polymer-based composite material self-healing nano-capsules are composed of 30-70 parts of urea, 40-150 parts of formaldehyde solution, 50-300 parts by weight Parts of dicyclopentadiene, 1 to 6 parts of sodium dodecylbenzenesulfonate, 2 to 7 parts of resorcinol, 1 to 6 parts of n-butanol, 1 to 6 parts of octane, 20 to 40 parts (3, 2-glycidoxy) propyltrimethoxysilane and 50-500 parts of deionized water. Others are the same as the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com