Preparation method of highly flame-retardant and environment-friendly thermoplastic polyurethane elastomer

A thermoplastic polyurethane and elastomer technology, which is applied in the field of preparation of highly flame-retardant and environmentally friendly thermoplastic polyurethane elastomers, can solve the problems that the flame-retardant properties of TPU have not been satisfactorily resolved and restrict the application of TPU, so as to ensure excellent performance and less loss of mechanical properties , the effect of high oxygen index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

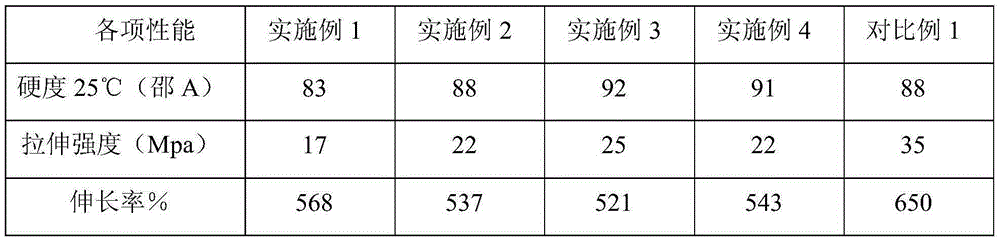

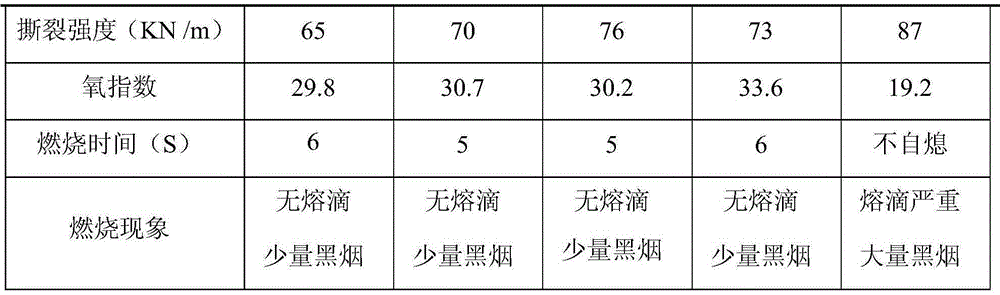

[0022] Preparation of high flame retardant and environmentally friendly thermoplastic polyurethane elastomer: polytetrahydrofuran diol (PTMG2000, M=2000), adding dimethyl methylphosphonate (DMMP), vacuum removal of moisture at 110 ° C, diphenylmethane diisocyanate (MDI ) and 1,4-butanediol (BDO) were incubated at 45°C and 40°C, respectively. PTMG2000: 200g, MDI: 89.7g, BDO: 22.8g, DMMP: 31.3g were mixed uniformly, and the isocyanate index was 1.01. The above materials are vigorously stirred, the mixed materials are injected into the twin-screw reactor, and TPU particles are obtained by continuous reaction.

[0023] Take 200 g of the prepared TPU pellets and add them to a plastic mill, and heat up to 180 °C for plasticizing for 1 min to melt uniformly. Add 18.8g of nanometer magnesium hydroxide (MgOH) and 25g of ammonium polyphosphate (APP) to the molten TPU, continue to masticate for 1min, unload the material to a 160°C flat vulcanizer, and press it into a TPU sheet of standa...

Embodiment 2

[0026] According to the preparation method of Example 1.

[0027] Preparation of high flame retardant and environmentally friendly thermoplastic polyurethane elastomer: PTMG2000: 200g, MDI: 105g, BDO: 28.3g, DMMP: 33.3g, nano-MgOH: 20g, APP: 26.7g.

[0028] Its performance testing method is the same as that of Example 1, and the results are shown in Table 1.

Embodiment 3

[0030] According to the preparation method of Example 1.

[0031] Preparation of high flame retardant and environmentally friendly thermoplastic polyurethane elastomer: PTMG2000: 200g, MDI: 122.6g, BDO: 34.6g, DMMP: 35.7g, nano-MgOH: 21.4g, APP: 28.6g.

[0032] Its performance testing method is the same as that of Example 1, and the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com