Continuous production process for enabling gold metal to be firmly attached to aromatic special fiber filaments

A technology of special fiber and production process, which is applied in the direction of fiber type, fiber treatment, ultrasonic/sonic fiber treatment, etc., which can solve the problems of easy volatilization, fiber strength damage, no adhesion, etc., and achieve strength retention, light weight, and mechanical properties The effect of less loss and maintaining the original strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

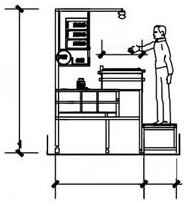

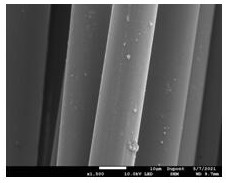

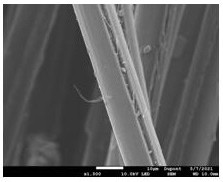

[0019]The specific production process steps are as follows. All processes are carried out on the automatic line according to the set sub-slot length, set speed, and fixed parameters. The process of polyimide fiber is as follows: 1. Alkaline cleaning: the aromatic polyimide The imide fiber is passed through a 3% sodium hydroxide solution with ultrasonic vibration, the time is 2 minutes, and the temperature is 40°C; 2. Three times of overflow washing with pure water: wash with ultrapure water for 3 times, a total of 1 minute, and add ultrasonic wave Oscillation; 3. Coarsening: 60% concentrated sulfuric acid, add 40g / L WN-LL213 expansion agent (temperature 30°C, time 30 seconds), supplemented by mechanical vibration, amplitude 3.5cm, vibration frequency 30 times / min , in order to achieve the premise that the fiber does not break, each fiber filament forms longitudinal micro-cracks; 4. Three overflow washings with pure water: wash 3 times with ultra-pure water, a total of 1 minute,...

Embodiment 2

[0022] The specific production process steps are as follows. The aromatic fiber of Yantai Taihe New Materials is 500D aramid fiber 1414. All processes are carried out on the automatic line according to the set sub-slot length, set speed, and fixed parameters. The fiber passing process is as follows: 1 1. Alkaline cleaning: pass aramid 1414 fiber through 10% sodium hydroxide solution, add ultrasonic vibration, the time is 2 minutes, and the temperature is 60 ℃; 2. Three times overflow washing with pure water: wash 3 times with ultrapure water, a total of 1 minute , plus ultrasonic oscillation; 3. Coarsening: 80% concentrated sulfuric acid, add 40g / L WN-LL213 expansion agent, (temperature 40°C, time 30 seconds), supplemented by mechanical vibration, the amplitude is 3.5cm, and the vibration frequency is 200 times / min, in order to achieve the formation of longitudinal micro-cracks in each fiber without breaking the fiber; 4. Three times of overflow washing with pure water: wash wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com