Method for quickly and efficiently recycling high-performance resin-based carbon fiber composite material

A composite material and resin-based technology, which is applied in the field of rapid and efficient recycling of high-performance resin-based carbon fiber composite materials, can solve problems such as poor practicability, and achieve the effect of high recycling efficiency and mild conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Step 1. Take a cut piece of amine-cured epoxy resin-based carbon fiber composite material, after cleaning and drying, its mass is 2.070g, and its volume is 35×15×3mm 3 .

[0022] Step 2. Put the composite material in step 1 into a CH3COOH solution, react at a constant temperature of 108°C for 40 minutes, wash it with water several times, and dry it in an oven at 95°C until it reaches a constant weight.

[0023] Step 3. Take the composite material pretreated in step 2 and add it to a mixture of 0.02 g / mL DMSO and KOH, and react at 165° C. for 50 minutes.

[0024] Step 4. Separating the obtained solid product (carbon fiber), washing with water for several times, and drying in an oven at 95° C. until constant weight.

[0025] The mass of recycled carbon fiber was weighed to be 1.207g, and the degradation rate was 98.3%. The mechanical properties of the recycled carbon fiber reach 96% of the original fiber.

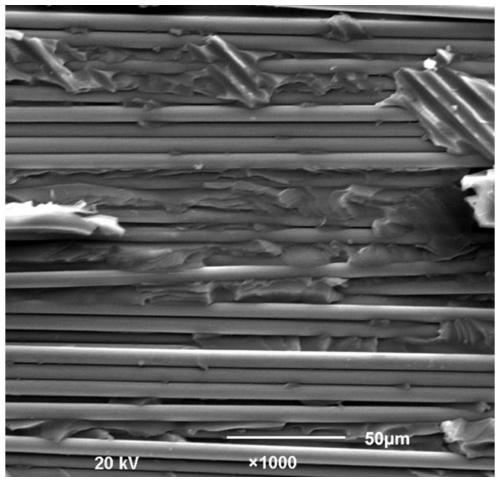

[0026] From figure 1 It can be seen that there is still a lar...

Embodiment 2

[0028] Step 1. Take a cut piece of amine-cured epoxy resin-based carbon fiber composite material. After cleaning and drying, its mass is 2.002g and its volume is 40×25×3mm 3 .

[0029] Step 2. Put the composite material in step 1 into a CH3COOH solution, react at a constant temperature at 110°C for 35 minutes, wash it with water several times, and dry it in an oven at 93°C until it reaches a constant weight.

[0030] Step 3. Take the composite material pretreated in step 2 and add it to a mixture of 0.10 g / mL DMSO and KOH, and react at 150° C. for 70 minutes.

[0031] Step 4. The obtained solid product (carbon fiber) is separated, washed with water for several times, and dried in an oven at 93° C. to constant weight.

[0032] The mass of recycled carbon fiber was weighed to be 1.182g, and the degradation rate was 96.6%. The mechanical properties of the recycled carbon fiber reach 98% of the original fiber.

Embodiment 3

[0034] Step 1. Take a cut piece of amine-cured epoxy resin-based carbon fiber composite material, after cleaning and drying, its mass is 2.032g, and its volume is 30×15×3mm 3 .

[0035] Step 2. Put the composite material in step 1 into CH 3 In the solution of COOH, react at a constant temperature at 112°C for 30min, wash with water several times, and dry in an oven at 90°C until constant weight.

[0036] Step 3. Take the composite material pretreated in step 2 and add it to a mixture of 0.06 g / mL DMSO and KOH, and react at 180° C. for 40 minutes.

[0037] Step 4. Separating the obtained solid product (carbon fiber), washing with water for several times, and drying in an oven at 90° C. to constant weight.

[0038] The mass of recycled carbon fiber was weighed to be 1.177g, and the degradation rate was 99.2%. The mechanical properties of the recovered carbon fiber can reach 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com