High-temperature-resistant humidity-resistant glass fiber reinforced nylon composite material and preparation method thereof

A nylon composite material, high temperature resistant technology, applied in the field of engineering plastics, to achieve the effect of increasing the interface area, improving the dispersion uniformity, and increasing the interface bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

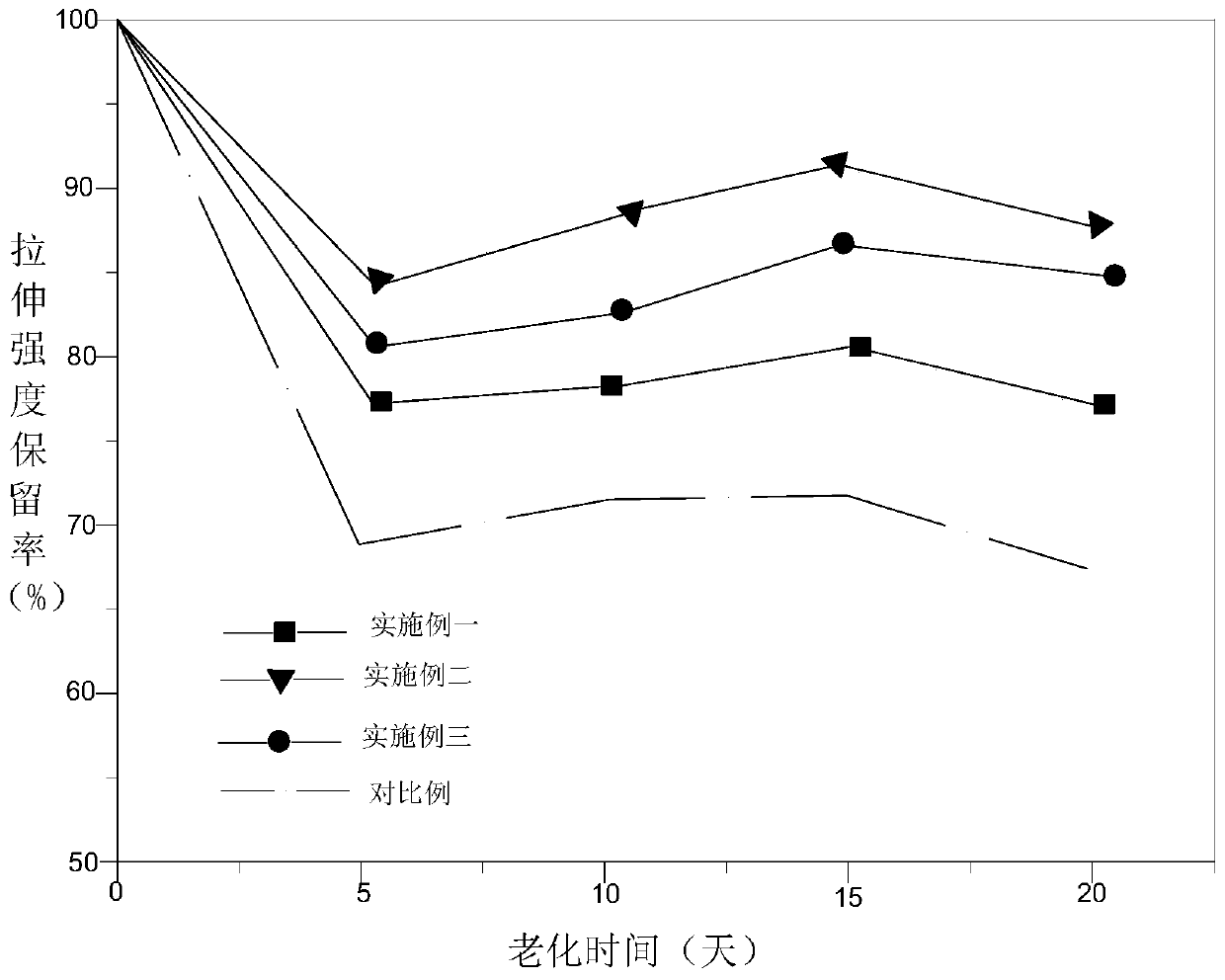

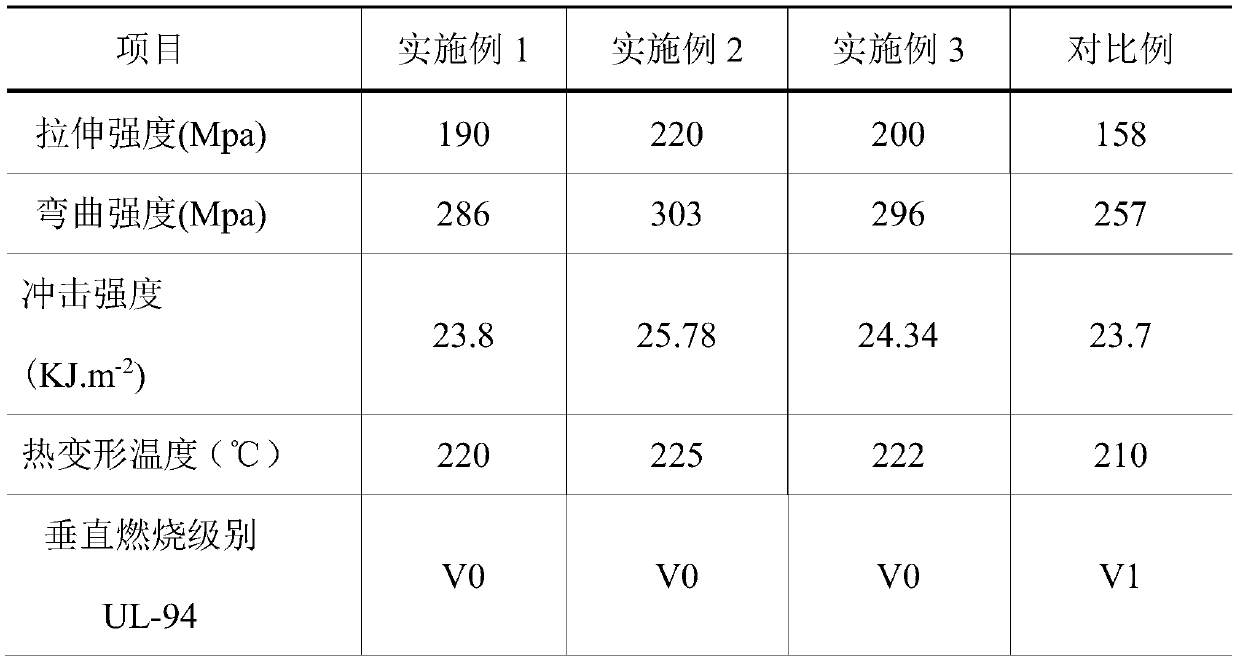

Examples

Embodiment 1

[0031] A high-temperature and moisture-resistant glass fiber reinforced nylon composite material, the preparation raw materials of which include the following components by mass percentage: nylon 66 30%, polyphthalamide resin 25%, long glass fiber 15%, polycarbonate 10% %, inorganic filler 5%, modified sepiolite 5%, compatibilizer 2.5%, lubricant 1.5%, impact modifier 2.5% and flame retardant 3.5%.

[0032] Among them, the glass fiber is alkali-free glass fiber treated with silane coupling agent; the inorganic filler is talc; the modified sepiolite is the sepiolite which has been treated by acidification modification and organic modification in turn; the compatibilizer is Malay The acid anhydride grafted ethylene-octene copolymer; the lubricant is a silicone resin lubricant; the impact modifier is an acrylate type modifier, and the acrylate type modifier takes the acrylate type copolymer as the core to connect The branched methacrylate copolymer is a core-shell structure modif...

Embodiment 2

[0038] A high-temperature and moisture-resistant glass fiber reinforced nylon composite material, the preparation raw materials of which include the following components by mass percentage: nylon 66 35%, polyphthalamide resin 20%, long glass fiber 20%, polycarbonate 5% %, inorganic filler 10%, modified sepiolite 7%, compatibilizer 1%, lubricant 1%, impact modifier 0.5% and flame retardant 0.5%.

[0039]Among them, the glass fiber is alkali-free glass fiber treated with silane coupling agent; the inorganic filler is mica powder; the modified sepiolite is the sepiolite which has been treated by acidification modification and organic modification in turn; the compatibilizer is Malay Acid anhydride grafted ethylene propylene rubber; lubricant is silicone resin lubricant; impact modifier is acrylate type modifier, the acrylate type modifier is based on acrylate copolymer as the core, to graft The methacrylate copolymer is the core-shell structure modifier of the shell; the flame re...

Embodiment 3

[0045] A high-temperature-resistant and moisture-resistant glass fiber reinforced nylon composite material, the preparation raw materials of which include the following components by mass percentage: nylon 66 40%, polyphthalamide resin 15%, long glass fiber 10%, polycarbonate 8% %, inorganic filler 15%, modified sepiolite 3%, compatibilizer 5%, lubricant 0.5%, impact modifier 1.5% and flame retardant 2%.

[0046] Among them, the glass fiber is alkali-free glass fiber treated with silane coupling agent; the inorganic filler is diatomite; the modified sepiolite is the sepiolite which has been treated by acidification modification and organic modification in turn; the compatibilizer is acrylic acid Glycidyl ester; the lubricant is a silicone resin lubricant; the impact modifier is an acrylate type modifier, the acrylate type modifier is based on an acrylate copolymer as the core, and the grafted methacrylate The copolymer is a core-shell structure modifier of the shell; the flame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com