A cleaning method and device for regeneration of waste denitrification catalyst

A technology for denitrification catalysts and cleaning devices, applied in catalyst regeneration/reactivation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as activity decline, achieve high recovery, avoid secondary pollution, and device structure full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

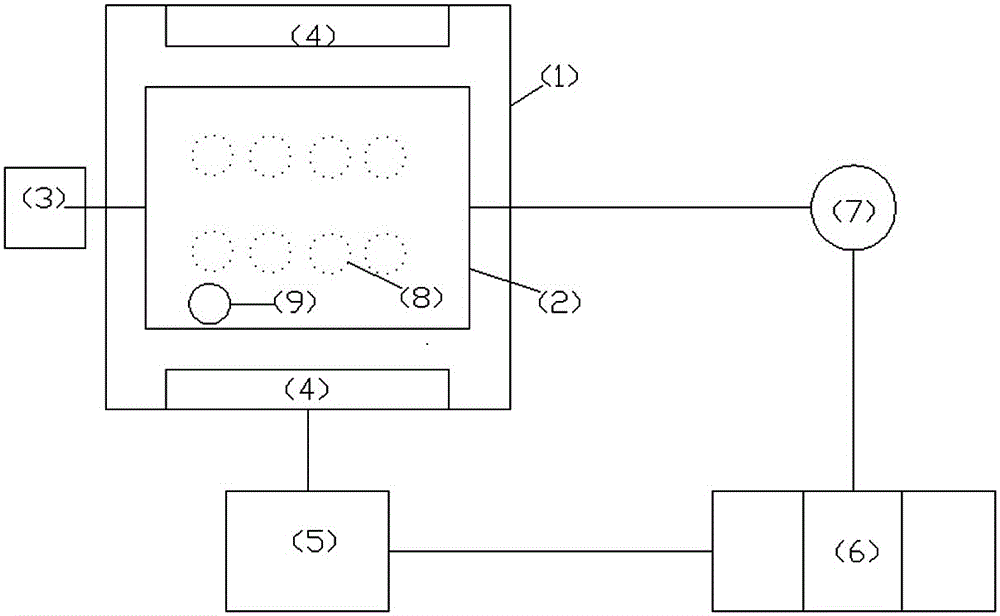

[0026] (1) Take a 2×1×1.2m denitrification catalyst module, whose catalytic efficiency is reduced from 87% to 45%, and place it in the module rotating box 2. The channel direction of the catalyst module is vertical, and a movable high-pressure water gun is used 9. Adjust the pressure to 5MPa to flush the catalyst module channel for 30 minutes; add water until it just submerges the catalyst module channel, and the aeration pipe 8 passes 3kg pressure steam to heat and clean the water in the box 1 to 60°C; the aeration pipe 8 passes 8kg pressure steam Compressed air for water and air cleaning operation; use the geared motor 3 to rotate the module rotation box 2 until the direction of the catalyst module hole is horizontal, and the ultrasonic vibration plate 4 starts and adjusts the frequency to 20kHz to perform ultrasonic cleaning on the catalyst module hole, and the cleaning time is 60min;

[0027] (2) Put the cleaning water in the cleaning box 1 into the sedimentation tank 5, us...

Embodiment 2

[0033] (1) Take a 2×1×1.2m denitrification catalyst module, whose catalytic efficiency is reduced from 87% to 45%, and place it in the module rotating box 2. The channel direction of the catalyst module is vertical, and a movable high-pressure water gun is used 9 Adjust the pressure to 10MPa to flush the catalyst module channel for 45 minutes; add water until it just submerges the catalyst module channel, and the aeration pipe 8 passes 3kg pressure steam to heat and clean the water in the box 1 to 70°C; the aeration pipe 8 passes 8kg pressure steam Compressed air for water and air cleaning operation; use the geared motor 3 to rotate the module rotation box 2 until the direction of the catalyst module hole is horizontal, and the ultrasonic vibration plate 4 starts and adjusts the frequency to 50kHz to perform ultrasonic cleaning on the catalyst module hole, and the cleaning time is 90min;

[0034] (2) Put the cleaning water in the cleaning box 1 into the settling tank 5, use the...

Embodiment 3

[0040] (1) Take a 2×1×1.2m denitrification catalyst module, whose catalytic efficiency is reduced from 87% to 45%, and place it in the module rotating box 2. The channel direction of the catalyst module is vertical, and a movable high-pressure water gun is used 9 Adjust the pressure to 15MPa to flush the catalyst module channel for 60 minutes; add water until it just submerges the catalyst module channel, and the aeration pipe 8 passes 3kg pressure steam to heat and clean the water in the box 1 to 80°C; the aeration pipe 8 passes 8kg pressure steam Compressed air for water and air cleaning operation; use the geared motor 3 to rotate the module rotation box 2 until the direction of the catalyst module hole is horizontal, and the ultrasonic vibration plate 4 starts and adjusts the frequency to 80kHz to perform ultrasonic cleaning on the catalyst module hole, and the cleaning time is 80min;

[0041] (2) Put the cleaning water in the cleaning box 1 into the sedimentation tank 5, us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com