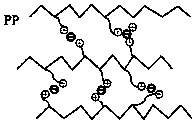

Reversible micro-crosslinking high melt strength polypropylene and preparation method thereof

A high-melt-strength, polypropylene technology, applied in the field of reversible micro-crosslinking high-melt-strength polypropylene and its preparation, can solve the problems of complicated operation and high equipment investment, achieve small loss of mechanical properties, improve material properties, and improve the The effect of liquidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

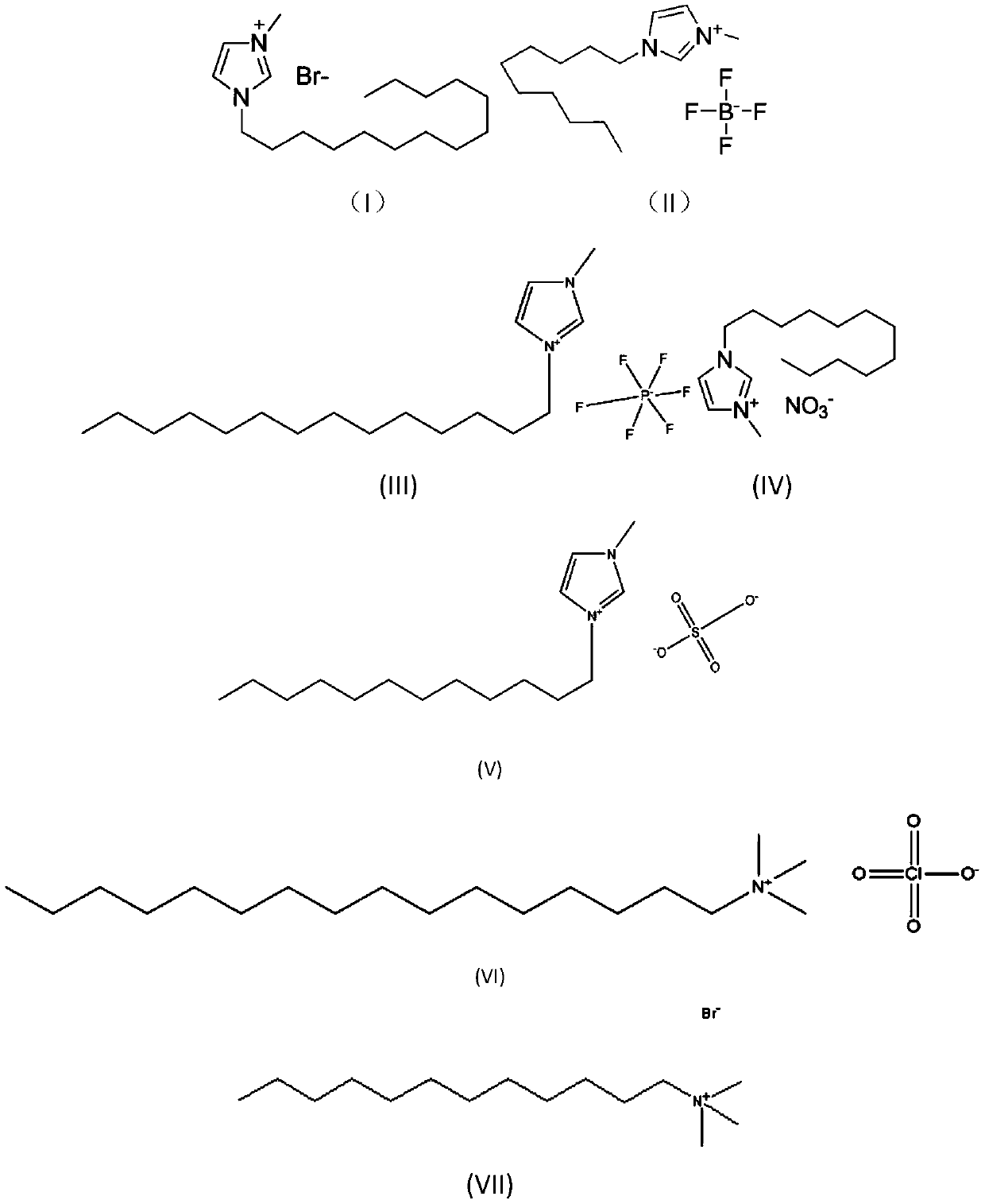

[0028] (1) Mixing of raw materials: mix 10000 grams of polypropylene (Qilu Petrochemical, melt index 3.5 grams / 10 minutes, grade T30s), 10 grams of 2,5-dimethyl-2,5-bis(tert-butylperoxy) Hexane (Bai Lingwei Technology Co., Ltd.), 20 grams of tetramethylthiuram disulfide (Bai Lingwei Technology Co., Ltd.) and 20 grams of 1-tetradecyl-3-methylimidazole bromide (West Asia reagent) in a high-speed mixer The mixing is uniform, the speed of the high-speed mixer is 100 rpm, and the mixing time is 10 minutes.

[0029] (2) Screw extrusion reaction: Add the mixed materials in step (1) to the twin-screw extruder for grafting reaction. The temperature of each screw is 195 / 205 / 205 / 210 / 210 / 215 / 215 / 215 / 210 / 210 / 195℃, the screw speed is 220 rpm.

[0030] (3) The reaction is terminated: 30 grams of antioxidant masterbatch, antioxidant 1010 (primary antioxidant) and antioxidant 168 (secondary antioxidant), the mass ratio of primary / secondary antioxidant is 1:1 from the screw The feeding port on th...

Embodiment 2

[0033] The raw materials were mixed, reacted and terminated according to the method of Example 1, except that the active crosslinking agent used 1-dodecyl-3-methylimidazole nitrate ((C 12 Min + ) 2 NO 3 2- ), the dosage is 20 grams. The amount of each substance added during the extrusion process is shown in Table 1, and the test result is shown in Table 2.

Embodiment 3

[0035] The raw materials were mixed, reacted and terminated according to the method of Example 1, except that the amount of tetramethylthiuram disulfide was 25 grams. The amount of each substance added during the extrusion process is shown in Table 1, and the test result is shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com