High-transparency filling material as well as preparation method and application of high-transparency filling material

A filler and transparent technology, which is applied in the field of high-transparency filler and its preparation, can solve the problems of large influence on the transparency of packaging films and poor transparency, and achieve the effects of small loss of mechanical properties and reduced product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Add 100 parts by weight of PE (7042), 500 parts by weight of sodium sulfate, 100 parts by weight of starch and 10 parts by weight of surface treatment agent into a high-speed mixer, stir at a high speed for 30 minutes, and then extrude with a twin-screw extruder Granulation, that is, highly filled transparent masterbatch.

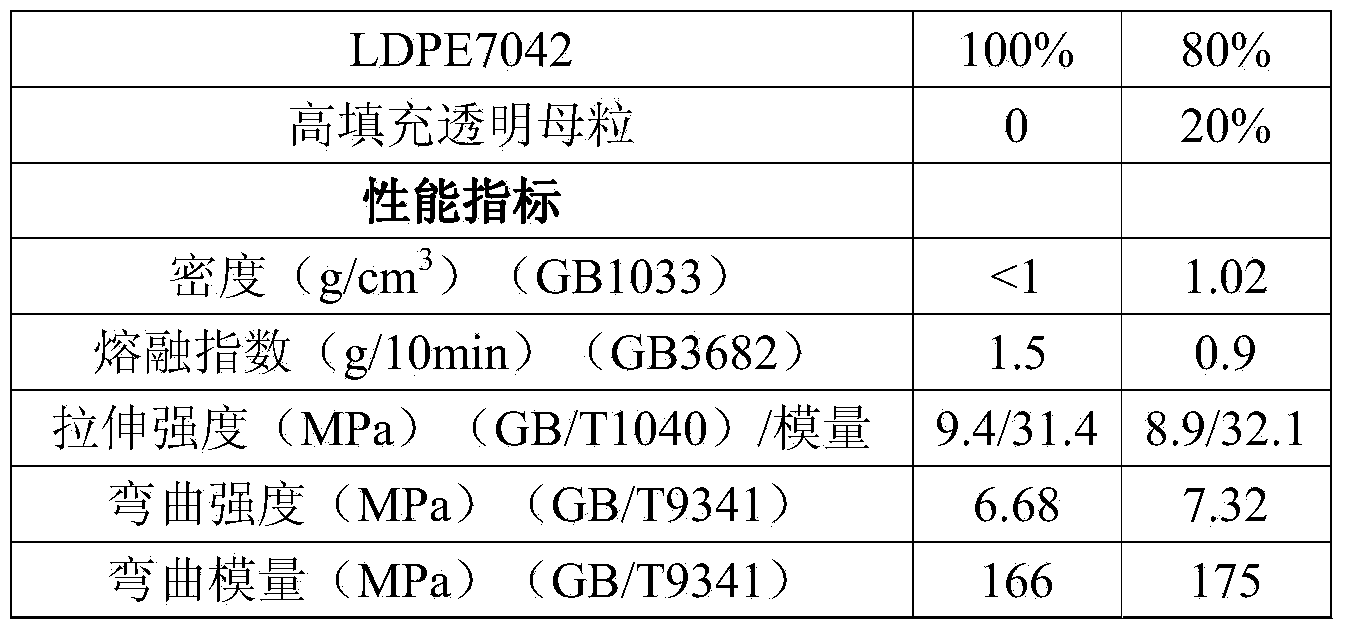

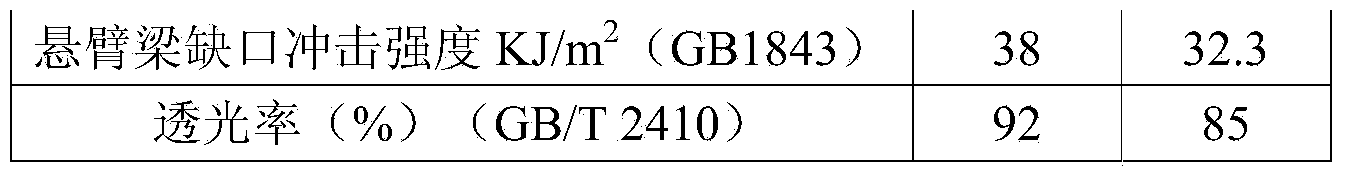

[0023] The prepared high-filling transparent masterbatch was added to LDPE7042 at a weight ratio of 20%, and the sample was tested for performance. The test results are shown in the table below.

[0024]

[0025]

Embodiment 2

[0027] Add 100 parts by weight of PE (7042), 600 parts by weight of sodium sulfate, 5 parts by weight of starch and 15 parts by weight of surface treatment agent into a high-speed mixer, stir at a high speed for 20 minutes, and then extrude with a twin-screw extruder Granulation, that is, highly filled transparent masterbatch.

[0028] The prepared high-filling transparent masterbatch was added to LDPE7042 at a weight ratio of 40%, and the sample was tested for performance. The test results are shown in the table below.

[0029] LDPE7042

Embodiment 3

[0031] Add 100 parts by weight of transparent PP, 60 parts by weight of 500-mesh sodium sulfate, 200 parts by weight of amylose and 50 parts by weight of silane coupling agent into a high-speed mixer, stir at high speed for 50 minutes, and then extrude with a twin-screw Machine extrusion granulation, that is, highly filled transparent masterbatch.

[0032] The prepared highly filled transparent masterbatch was added to the film raw material as a filler in a weight ratio of 15%, and the obtained result was close to that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com