Modified waste high impact polystyrene anti-aging master batch

A polystyrene, high-impact technology, applied in the field of waste high-impact polystyrene recycling, achieves the effects of low loss of mechanical properties, improved aging resistance, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

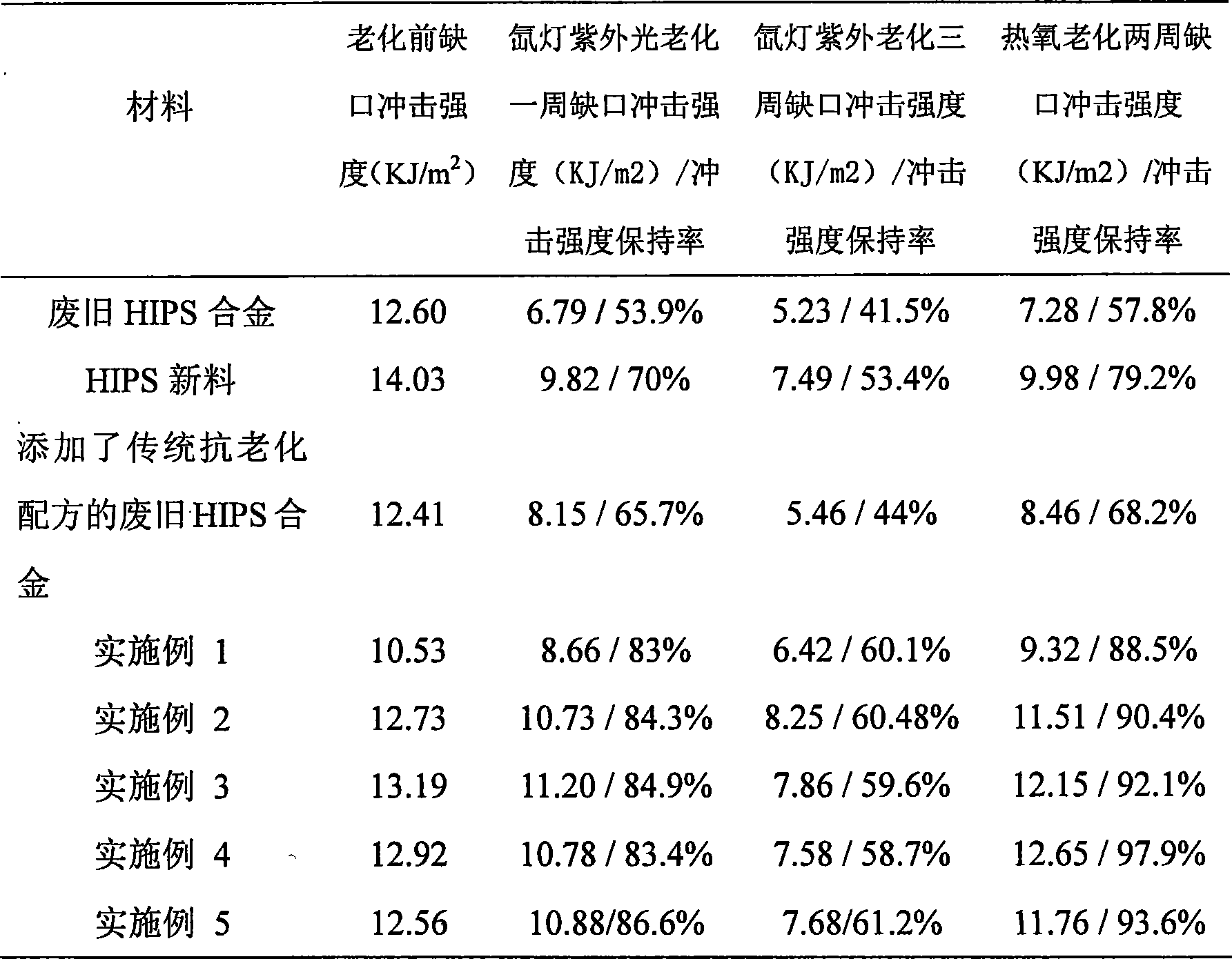

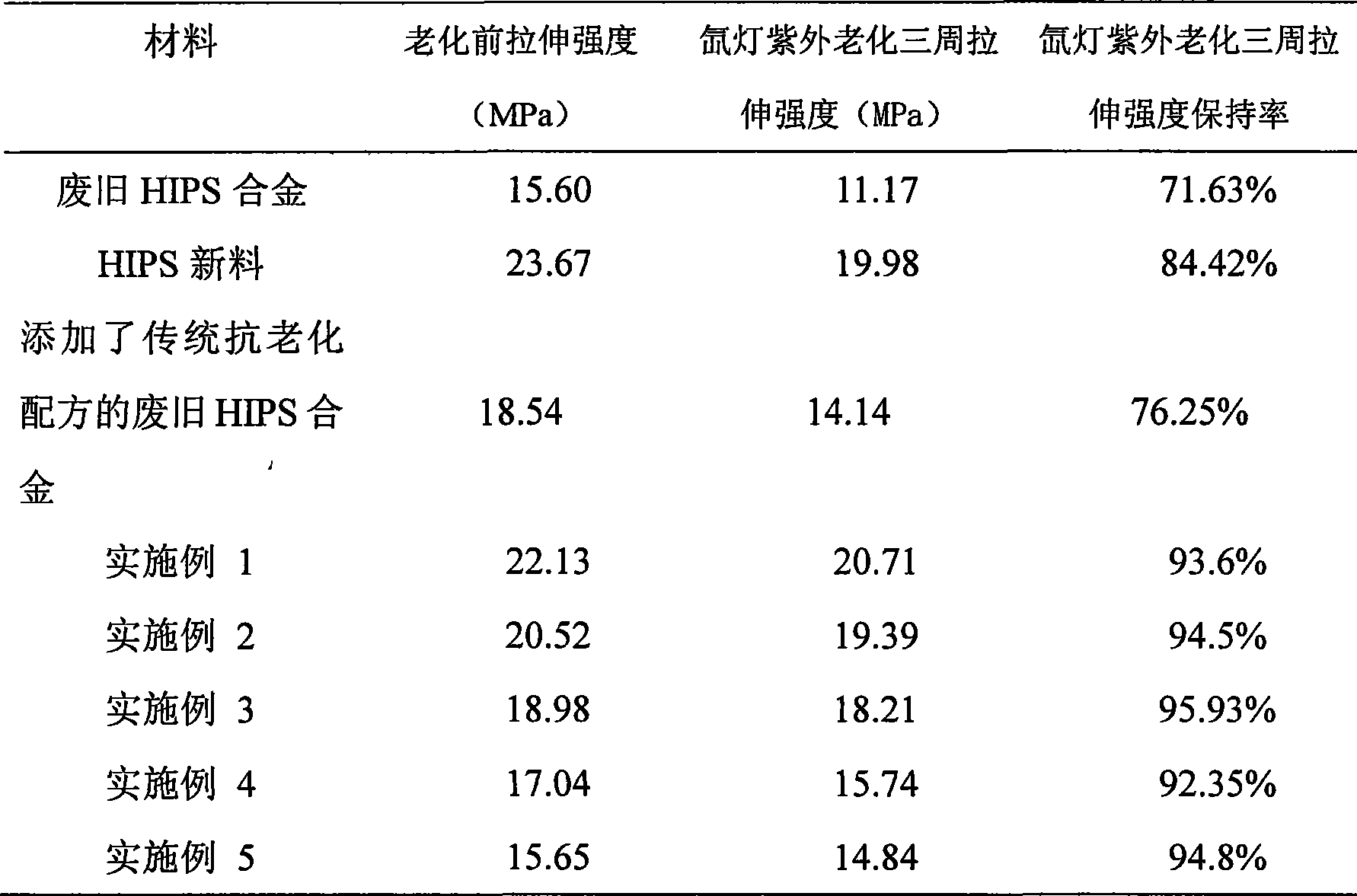

[0022] Put 95 parts of waste HIPS, 5 parts of polyolefin elastomer POE, 5 parts of linear low density polyethylene and 0.25 parts of 2-(2-hydroxyl-5-methylphenyl) benzotriazole into a high-speed machine with a rotation speed of 1000rpm Mix in the mixer for 5 minutes, then put it into a twin-screw extruder, and simultaneously dissolve 0.07 parts of dicumyl peroxide and titanate coupling agent that are 1:1 by weight 5 parts of styrene were added from the fiber port of the twin-screw extruder, and the temperatures in each zone were 150°C, 170°C, 190°C, 210°C, 210°C, 200°C, and the screw speed was 900 rpm. It can be obtained by mixing, extruding and granulating. The notched impact strength and tensile strength of the obtained anti-aging masterbatch, as well as the performance changes after aging are shown in Tables 2 and 3.

Embodiment 2

[0024] 90 parts of waste HIPS, 10 parts of styrene-butadiene rubber, 6 parts of linear low-density polyethylene and 0.5 parts of four-(4-hydroxy-3,5-tert-butylphenyl propionate) pentaerythritol ester and three (2,4 - Di-tert-butylphenyl) phosphite compound antioxidant composed of 1: 1.2 by weight was first put into a high-speed mixer with a speed of 1000rpm and mixed for 5 minutes, and then it was put into a twin-screw extruder , and at the same time, 6 parts of styrene that have been dissolved into 0.14 parts of dibenzoyl peroxide and propylene triisocyanate coupling agent in a weight ratio of 1:1 are added from the fiber port of the twin-screw extruder , under the conditions of temperature in each zone of 150°C, 170°C, 190°C, 210°C, 210°C, 200°C, and screw speed of 900 revolutions per minute, it can be obtained by melt blending, extruding and granulating. The notched impact strength and tensile strength of the obtained anti-aging masterbatch, as well as the performance chang...

Embodiment 3

[0026] Put 85 parts of waste HIPS, 15 parts of styrene-butadiene rubber, 7 parts of linear low density and 1 part of UV531 into a high-speed mixer with a rotation speed of 1000rpm and mix for 5 minutes, then put it into a twin-screw extruder, and simultaneously 7 parts of styrene that have been dissolved into 0.28 parts of dicumyl peroxide and titanate coupling agent in a weight ratio of 1:1 are added from the fiber port of the twin-screw extruder, and the temperatures in each zone are respectively 150°C, 170°C, 190°C, 210°C, 210°C, 200°C, and screw speed of 900 rpm under the conditions of melt blending extrusion granulation. The notched impact strength and tensile strength of the obtained anti-aging masterbatch, as well as the performance changes after aging are shown in Tables 2 and 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com