Preparation method of graded porous graphene material for super-capacitor

A supercapacitor, hierarchical porous technology, applied in graphene, nano-carbon and other directions, can solve the problems of cumbersome peeling and pressing molding process, high price of raw material - graphite oxide, cumbersome preparation process, etc., to achieve obvious energy saving effect, increase capacity and Rate performance, effect of simplifying preparation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

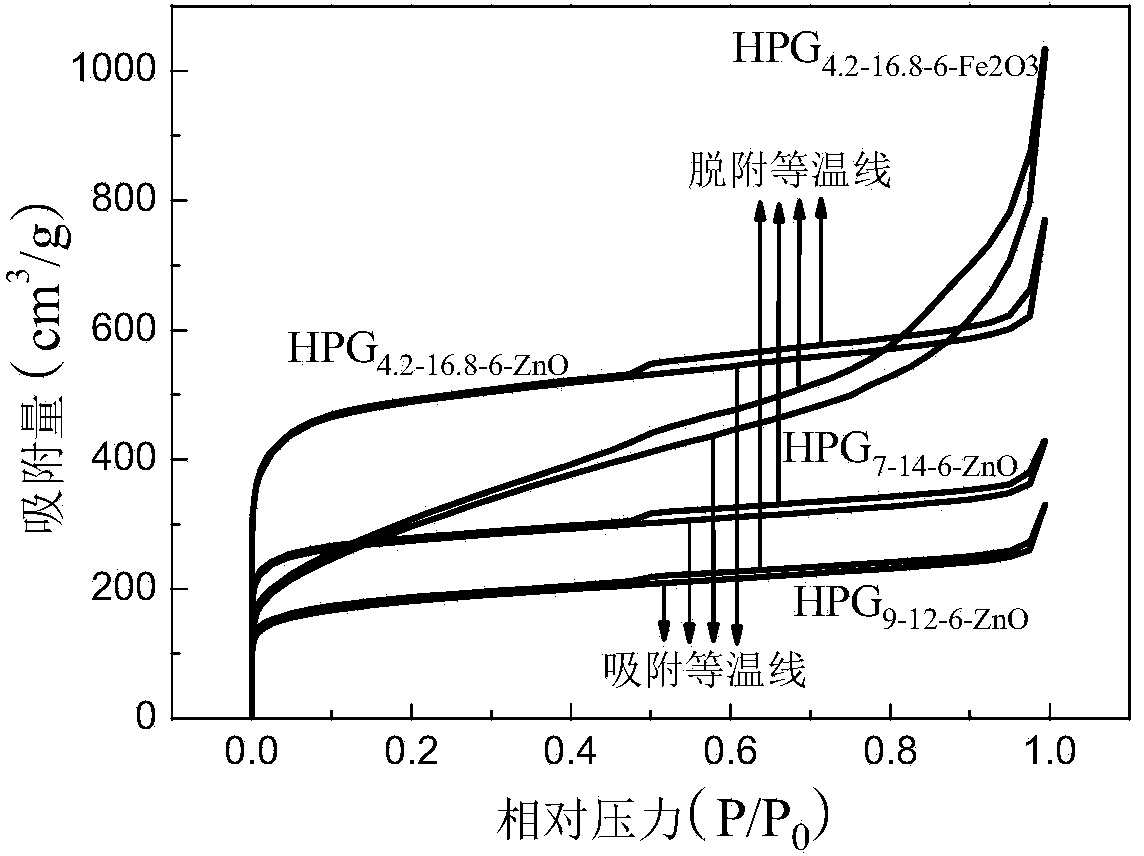

[0021] Embodiment 1: hierarchical porous graphene material HPG 4.2-16.8-6-ZnO Concrete preparation process is as follows:

[0022] (1) Pretreatment of reactants: After grinding the coal tar pitch, weigh 4.2g of coal tar pitch with a particle size of less than 74μm and put it into a mortar, add 16.8g of nano-zinc oxide, and then add 6g of solid potassium hydroxide. After the three reactants were mixed and ground for 1 hour, they were placed in a ball mill and ball milled at a speed of 303 r / min for 20 minutes to obtain the reactants;

[0023] (2) Preparation of hierarchical porous graphene material: Put the reactant obtained in step (1) into a porcelain boat, place it in a tube furnace, first pass nitrogen gas for 5 minutes to exhaust the air in the tube furnace, and then stop Ventilate nitrogen, turn on the vacuum pump to reduce the pressure in the tube furnace from normal pressure to -0.1MPa, heat up to 150°C at a heating rate of 5°C / min, keep the temperature for 0.5h, and c...

Embodiment 2

[0024] Embodiment 2: hierarchical porous graphene HPG 7-14-6-ZnO Concrete preparation process is as follows:

[0025] (1) Pretreatment of reactants: implemented in the same manner as step (1) in Example 1. The difference is that the weighed coal tar pitch is 7g, and the nanometer zinc oxide is 14g.

[0026] (2) According to the same method as step (2) in Example 1, the obtained hierarchical porous graphene material is marked as HPG 7-14-6-ZnO .

Embodiment 3

[0027] Embodiment 3: hierarchical porous graphene HPG 9-12-6-ZnO Concrete preparation process is as follows:

[0028] (1) Pretreatment of reactants: implemented in the same manner as step (1) in Example 1. The difference is that the weighed coal tar pitch is 9g, and the nanometer zinc oxide is 12g.

[0029] (2) According to the same method as step (2) in Example 1, the obtained hierarchical porous graphene material is marked as HPG 9-12-6-ZnO .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com