Porous graphene nanosheet, preparation method and application of porous graphene nanosheet as electrode material

A technology of porous graphene and nanosheets, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of reduced Coulombic efficiency of electrode materials, complex preparation process, and large pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

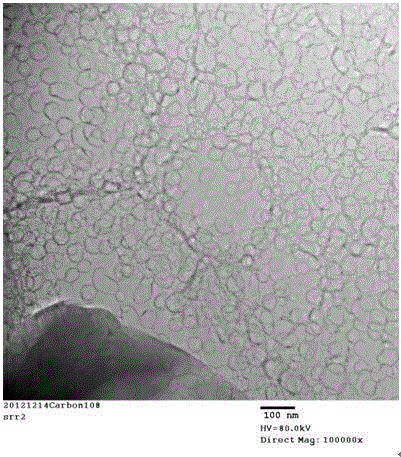

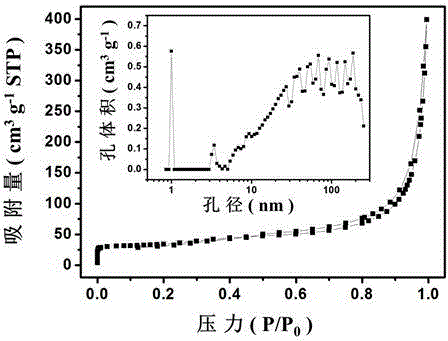

Embodiment 1

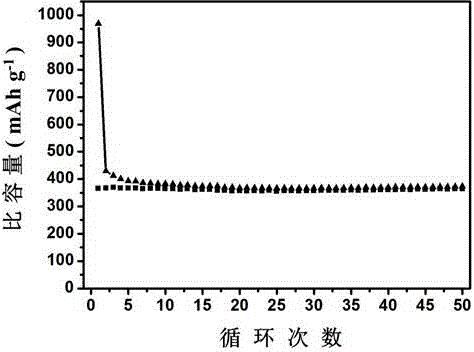

[0033] With phenolic resin 2.5g and copper nitrate (Cu(NO 3 ) 2 ·3H 2 O) 9.87g (atomic ratio Cu:C=1:4), and curing agent hexamethylenetetramine 0.35g, respectively dissolved in absolute ethanol, after the dissolution is complete, mix evenly, and stir naturally until the ethanol is completely volatilized. The mixture was cured in a vacuum oven at 150°C for 4 hours, and then the cured product was placed in a carbonization furnace and heated to 600°C for 6 hours under nitrogen protection. The carbonization product is a carbon sheet embedded with copper nanoparticles, which is immersed in 30% H 2 o 2 After the solution was oxidized for 2 hours, an excess of concentrated hydrochloric acid (36.8%~38%) was added, soaked in acid for about 12 hours, then filtered under reduced pressure, washed with deionized water until neutral, and dried to obtain a microporous, mesopore-rich Hierarchical pore structure carbon nanosheets. Put the hierarchical porous carbon sheet in a high-tempera...

Embodiment 2

[0038] Operating condition is the same as embodiment 1, and difference is that copper nitrate (Cu(NO 3 ) 2 ·3H 2 O) The mass was changed to 4.94g (atomic ratio Cu:C=1:8), and the carbonization condition was 800°C for 6 hours.

[0039] The resulting porous graphene nanosheets have a width of 5-15 μm, a thickness of about 2-15 nm, and a specific surface area of 96.3 m 2 / g. The electrochemical test was carried out by the same method as in Example 1, and the results showed that the reversible capacity reached 401.0 mAh / g at a current density of 50 mA / g, and the capacity remained at 350.3 mAh / g after 50 cycles. Under high current, the reversible capacity is 227.4 mAh / g when the current density is 1 A / g, and 147.8 mAh / g when the current density is 3 A / g.

Embodiment 3

[0041] Operating condition is the same as embodiment 1, and difference is that copper nitrate (Cu(NO 3 ) 2 ·3H 2 O) The mass was changed to 19.74g (atomic ratio Cu:C=1:2), and the solvent used was replaced by pyridine.

[0042] The resulting porous graphene nanosheets have a width of 1-8 μm, a thickness of about 1-10 nm, and a specific surface area of 298.4 m 2 / g. The electrochemical test was carried out by the same method as in Example 1, and the results showed that the reversible capacity reached 459.0 mAh / g at a current density of 50 mA / g, and the capacity remained at 397.8 mAh / g after 50 cycles. Under high current, the reversible capacity is 275.5 mAh / g when the current density is 1 A / g, 151.7 mAh / g when the current density is 3 A / g, and 118.9 mAh / g at 10 A / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com