Preparation method and application of rubidium lithium nickel-cobalt manganate

A technology of rubidium nickel cobalt manganate and rubidium cobalt manganate is applied in the application field of positive electrode materials of lithium ion batteries, which can solve the problems of unsatisfactory doping effect, difficulty in production and practical application, etc., and achieves uniform particles and equipment. The effect of simple, simple reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

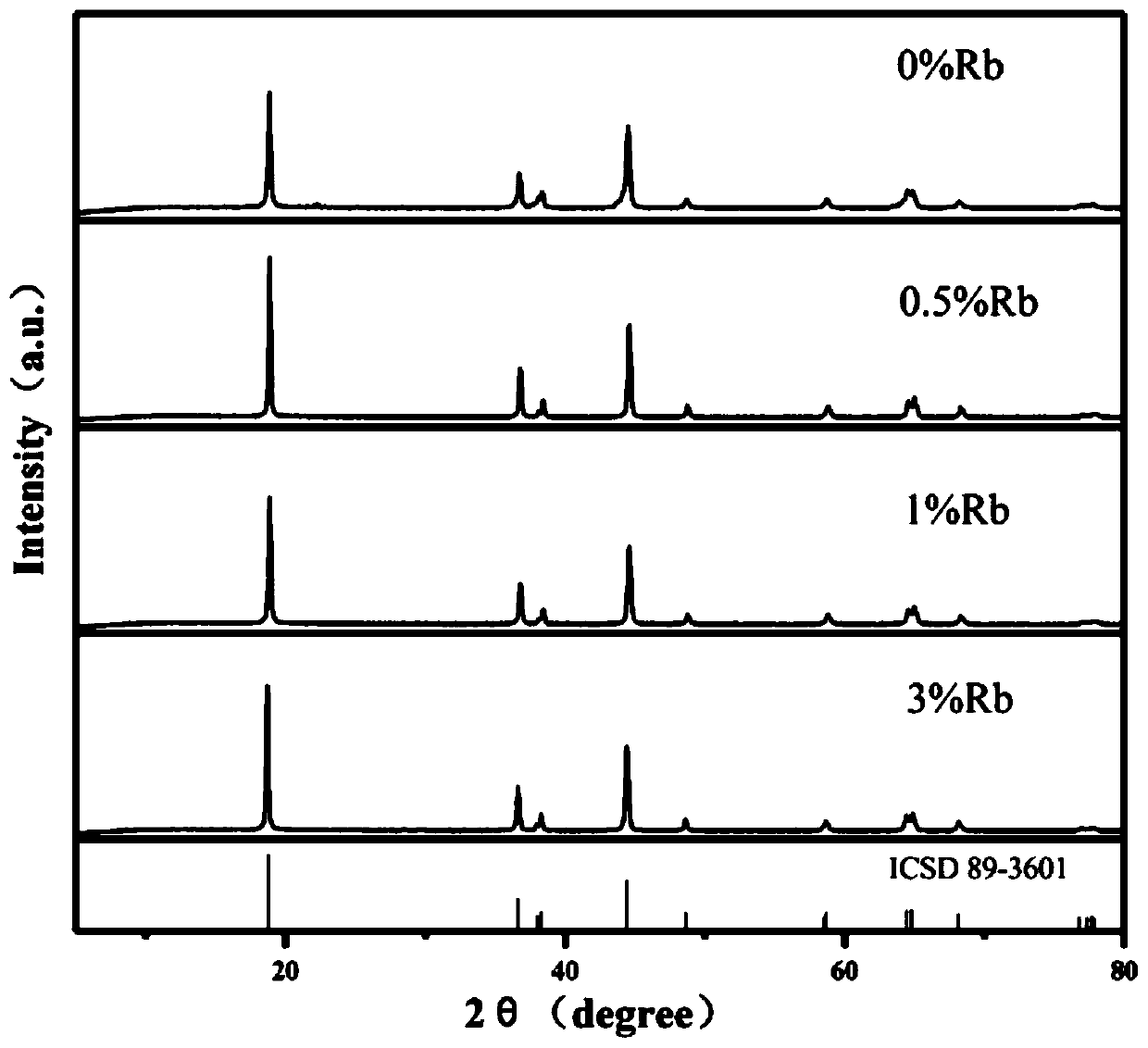

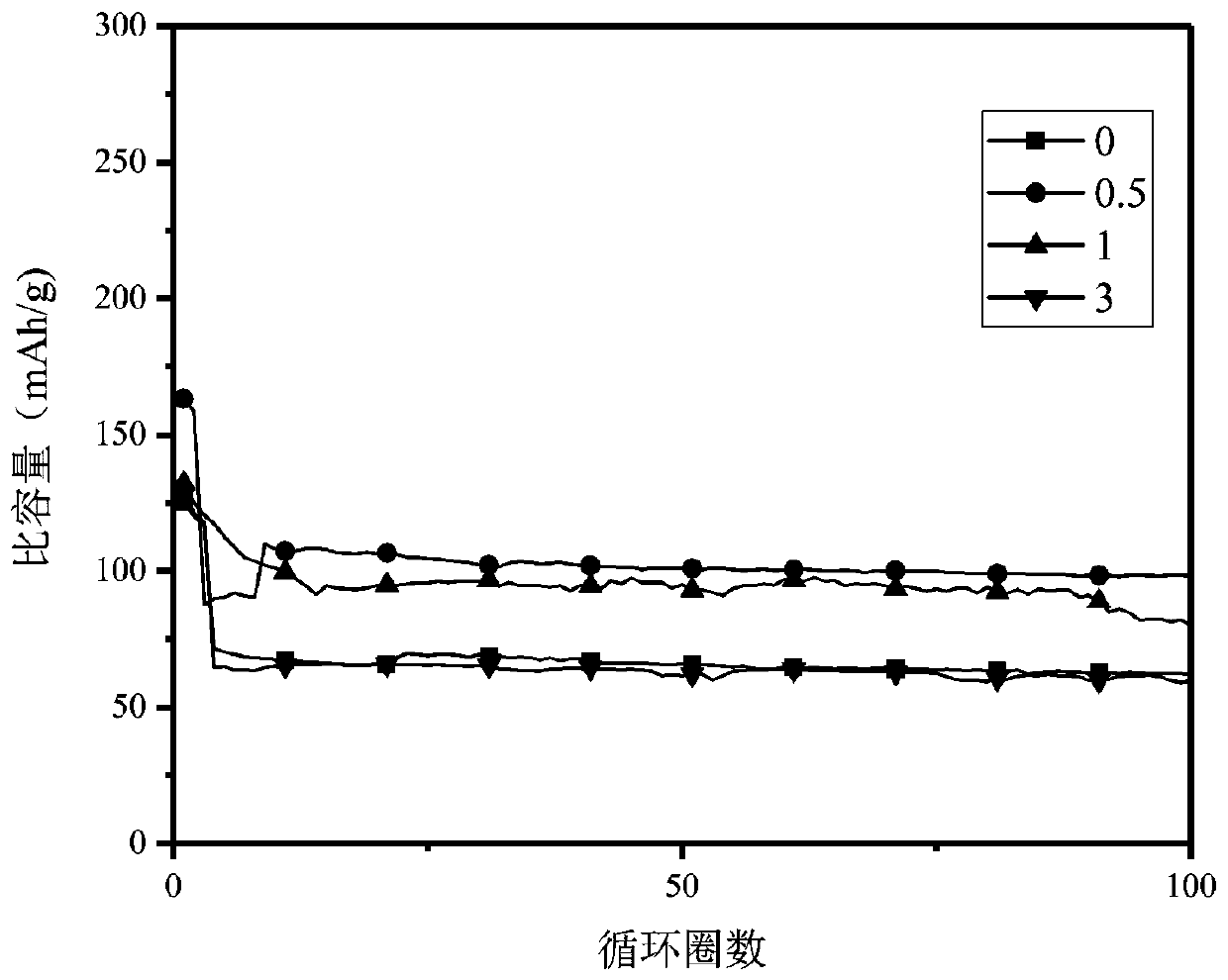

[0054] The target product of this embodiment is Li 0.995 Rb 0.005 Ni 0.8 co 0.1 mn 0.1 o 2 .

[0055] The high-nickel ternary material NCM811 precursor (Ni 0.8 co 0.1 mn 0.1 (OH) 2 ) with LiOH and Rb 2 CO 3 Weighing and mixing according to the stoichiometric ratio to obtain a mixture, in the mixture, in molar ratio, (Li+Rb):(Ni+Co+Mn)=1.045, in the mixture, in molar ratio, Rb:Li=0.005:0.995 .

[0056] The mixture was then mortared for 30 minutes and then transferred to a quartz boat placed in the center of the quartz tube of a tube furnace. Vacuum the quartz tube with O 2 The quartz tube is filled with gas, and the operation is repeated three times. Adjust the gas flow to 200 sccm (standard milliliters per minute). Carry out gradient temperature sintering, first raise the temperature to 450°C for 5 hours at 3°C / min, and then raise the temperature to 860°C at 2°C / min for sintering for 10 hours. After that, it was naturally cooled to room temperature with the fur...

Embodiment 2

[0061] The target product of this embodiment is Li 0.99 Rb 0.01 Ni 0.8 co 0.1 mn 0.1 o 2 .

[0062] The high-nickel ternary material NCM811 precursor (Ni 0.8 co 0.1 mn 0.1 (OH) 2 ) with LiOH and Rb 2 CO 3 Weighing and mixing according to the stoichiometric ratio to obtain a mixture, in the mixture, in molar ratio, (Li+Rb):(Ni+Co+Mn)=1.045:1, in the mixture, in molar ratio, n(Rb): n(Li)=0.01:0.99.

[0063] The mixture was then mortared for 30 minutes and then transferred to a quartz boat placed in the center of the quartz tube of a tube furnace. Vacuum the quartz tube with O 2 The quartz tube is filled with air, and the operation is repeated three times. Adjust the gas flow to 200 sccm (standard milliliters per minute). Carry out gradient temperature sintering, first raise the temperature to 450°C for 5 hours at 3°C / min, and then raise the temperature to 860°C at 2°C / min for sintering for 10 hours. After that, the furnace was naturally cooled to room temperature...

Embodiment 3

[0067] The target product of this embodiment is Li 0.97 Rb 0.03 Ni 0.8 co 0.1 mn 0.1 o 2 .

[0068] The high-nickel ternary material NCM811 precursor (Ni 0.8 co 0.1 mn 0.1 (OH) 2 ) with LiOH and Rb 2 CO 3 Weigh and mix according to the stoichiometric ratio to obtain the mixture, in the mixture, in molar ratio, (Li+Rb):(Ni+Co+Mn)=1.045, in the mixture, in molar ratio, n(Rb):n( Li) = 0.03:0.97.

[0069] The mixture was then mortared for 30 minutes and then transferred to a quartz boat placed in the center of the quartz tube of a tube furnace. Vacuum the quartz tube with O 2 The quartz tube is filled with gas, and the operation is repeated three times. Adjust the gas flow to 200 sccm (standard milliliters per minute). Carry out gradient temperature sintering, first raise the temperature to 450°C for 5 hours at 3°C / min, and then raise the temperature to 860°C at 2°C / min for sintering for 10 hours. After that, the furnace was naturally cooled to room temperature to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com