Tin selenide @ carbon nano fiber composite material, and preparation method and application thereof

A technology of carbon nanofibers and composite materials, applied in structural parts, electrical components, battery electrodes, etc., can solve the problems of complex preparation methods and high costs, and achieve the effects of simple and easy process, low cost and high reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

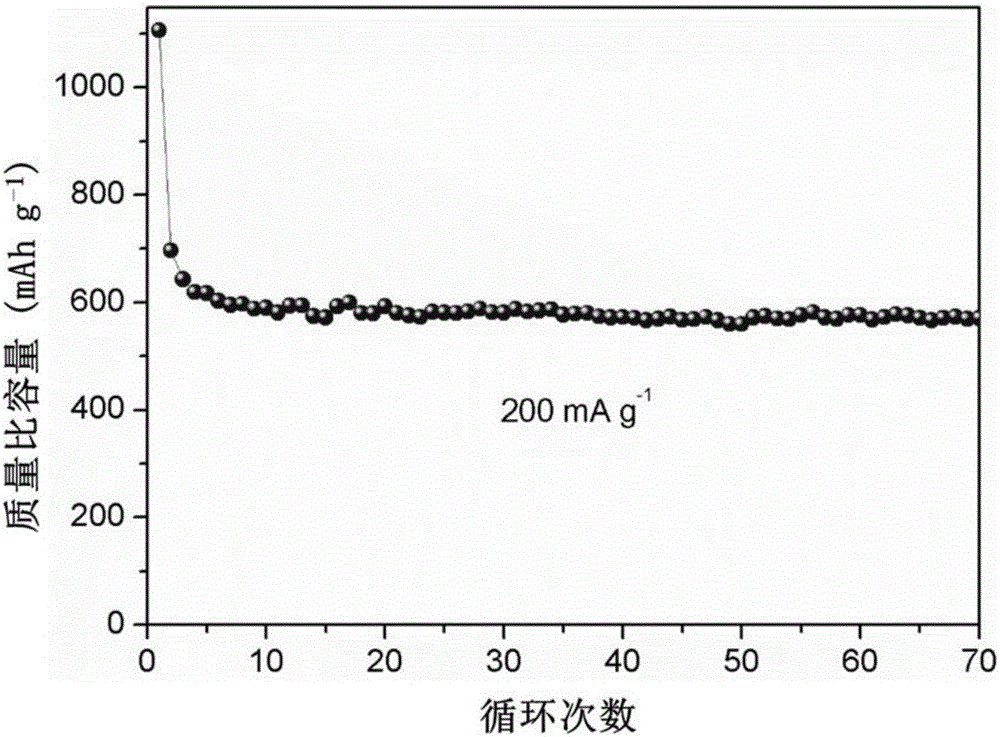

Examples

Embodiment 1

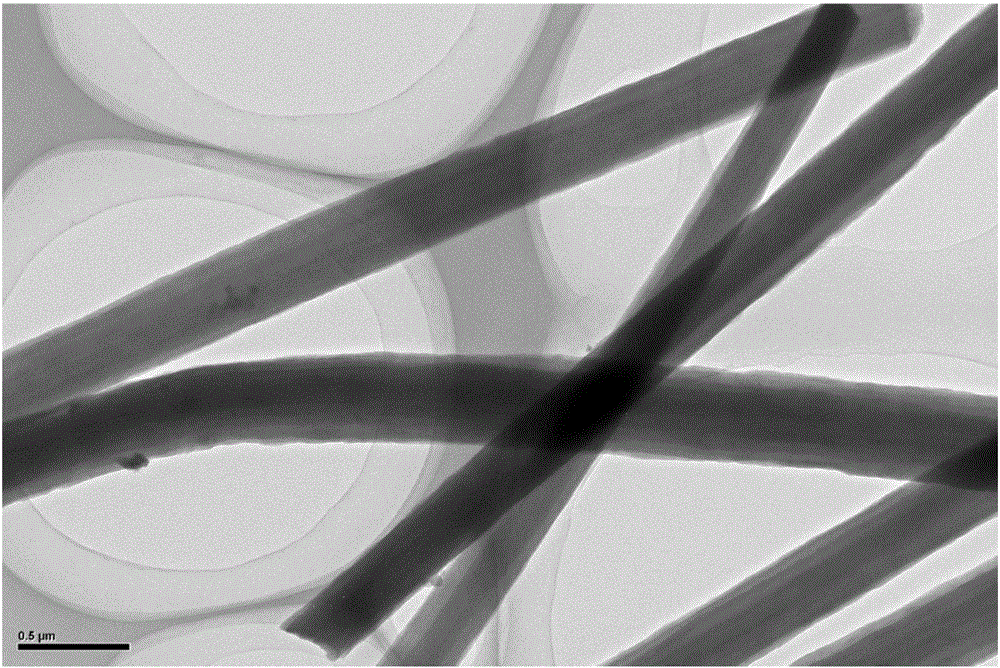

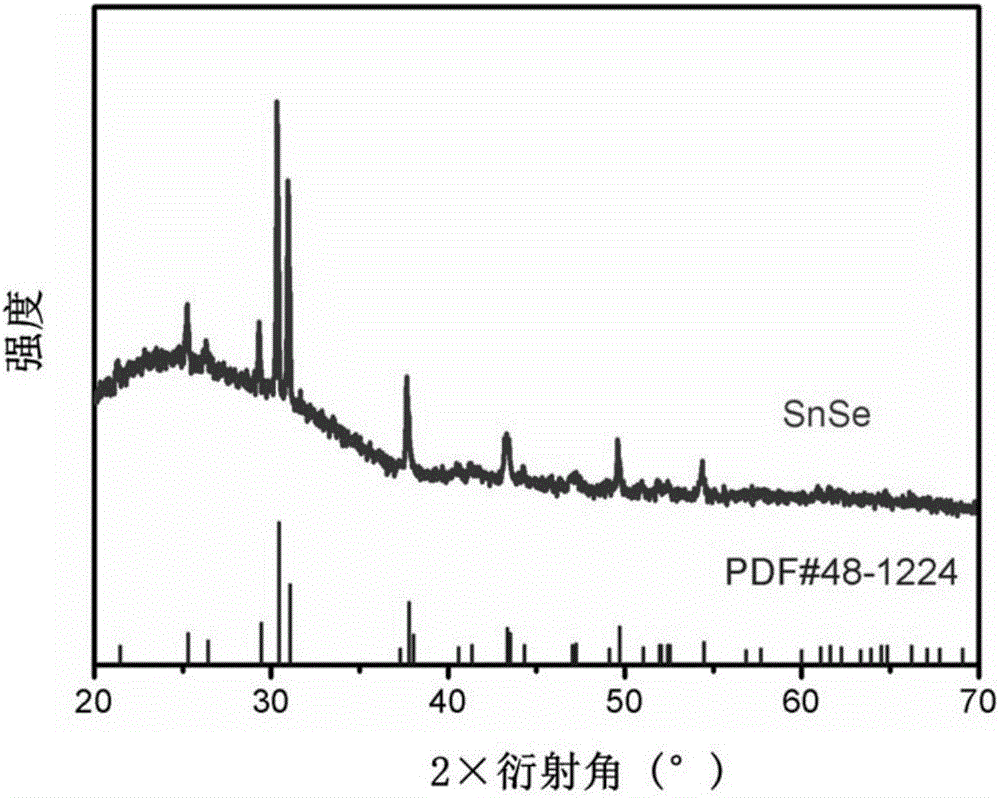

[0025] (1) Configure electrospinning precursor solution: 1g polyacrylonitrile (PAN; M w =150 000) was dissolved in 10 mL of N,N-dimethylformamide (DMF), and then stirred at 60°C for 5 h until completely dissolved. Then add 4mmol tin chloride and 4mmol selenium dioxide, and uniformly disperse all reactants under magnetic stirring to obtain an electrospinning precursor solution.

[0026] (2) Preparation of polymer nanofiber membrane by electrospinning method: put the electrospinning solution into a syringe, the inner diameter of the needle is 1.2 mm, the temperature is 25° C., and the relative humidity is 10%. Set the injection rate to 0.5ml / h, the voltage to 17kV, the rotational speed of the receiving drum to 900r / min, and control the receiving distance to 15cm. The polymer nanofiber membrane was obtained after spinning for 10 h.

[0027] (3) Heat treatment process: heat-treat the polymer nanofiber membrane obtained in step (2) at 600° C. under a nitrogen atmosphere, hold the...

Embodiment 2

[0029] (1) Configure electrospinning precursor solution: mix 1g polyvinylpyrrolidone (PVP; M w =1300 000) was dissolved in 10 mL of absolute ethanol, and then stirred at room temperature for 4 h until completely dissolved. Add 4mmol of selenium acetate and 4mmol of selenium powder, and disperse all reactants uniformly under magnetic stirring to obtain an electrospinning precursor solution.

[0030] (2) Preparation of polymer nanofiber membrane by electrospinning method: put the electrospinning solution into a syringe, the inner diameter of the needle is 0.9 mm, the temperature is 25° C., and the relative humidity is 10%. Set the injection rate to 0.4ml / h, the voltage to 12kV, the speed of the receiving drum to 600r / min, and control the receiving distance to 15cm. The polymer nanofiber membrane was obtained after spinning for 10 h.

[0031] (3) Heat treatment process: heat-treat the polymer nanofiber membrane obtained in step (2) at 700° C. under a nitrogen atmosphere, hold t...

Embodiment 3

[0033] (1) Configure electrospinning precursor solution: 0.5g polyacrylonitrile (PAN; M w =150 000) and 0.5 g of polyvinylpyrrolidone were dissolved in 10 mL of N,N-dimethylformamide (DMF), and then stirred at 60° C. for 5 h until completely dissolved. Then add 4 mmol of stannous chloride and 4 mmol of selenium dioxide, and uniformly disperse all reactants under magnetic stirring to obtain an electrospinning precursor solution.

[0034] (2) Preparation of polymer nanofiber membrane by electrospinning method: put the electrospinning solution into a syringe, the inner diameter of the needle is 0.9 mm, the temperature is 25° C., and the relative humidity is 10%. Set the injection rate to 1ml / h, the voltage to 17kV, the rotational speed of the receiving drum to 900r / min, and control the receiving distance to 20cm. The polymer nanofiber membrane was obtained after spinning for 7 h.

[0035] (3) Heat treatment process: heat-treat the polymer nanofiber membrane obtained in step (2)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com