Graphite compound modification method and lithium ion battery anode material preparation method

A compound modification and graphite technology, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of poor cycle life and electrochemical performance, improve charge-discharge specific capacity and reversible capacity, inhibit loosening and falling off, reduce embedding and The effect of resistance to dislodgement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

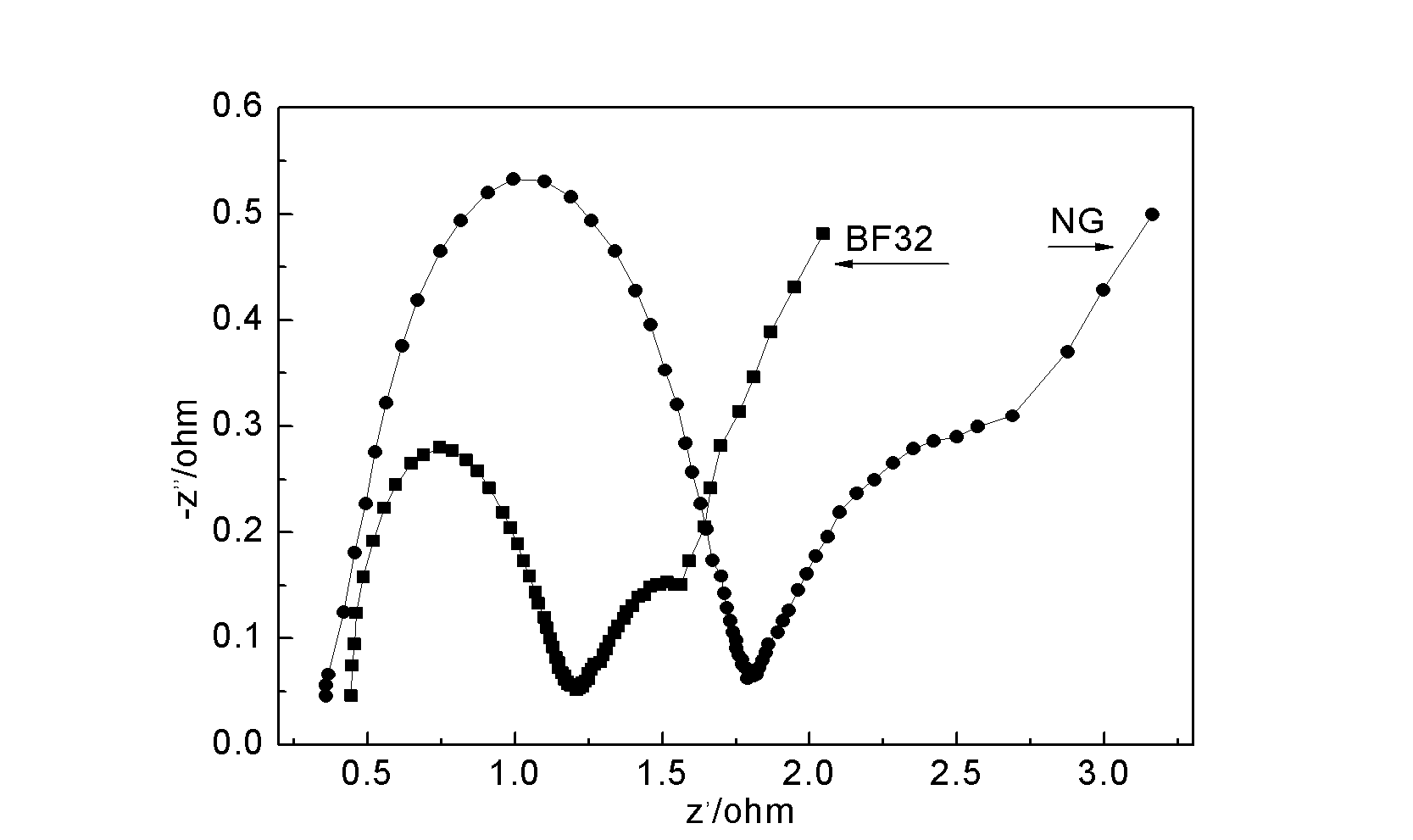

Examples

example 1

[0061] Example 1 The method of composite modification of graphite

[0062] The method for composite modification of graphite in the specific example of the present invention is mainly as follows:

[0063] 1. The process of oxidation modification mainly includes the following steps:

[0064] (1) Natural graphite is crushed and ball milled, and the ball milling time is referred to Table 2 respectively;

[0065] (2) Put the natural graphite after ball milling in a three-necked flask with concentrated nitric acid, preferably 63% concentrated nitric acid (analytical pure), stir at high speed at different temperatures, reflux reaction, 4h, reaction temperature 80 ℃ ~ 150 ℃, respectively Refer to Table 2;

[0066] (3) react the natural graphite after the reaction with the complexing agent propenylamine (EDPA) for 90min and cool to room temperature, wash repeatedly with distilled water to pH=7, and the mass percentage of graphite in the complexation reaction system is 90-95% ;

[...

example 2

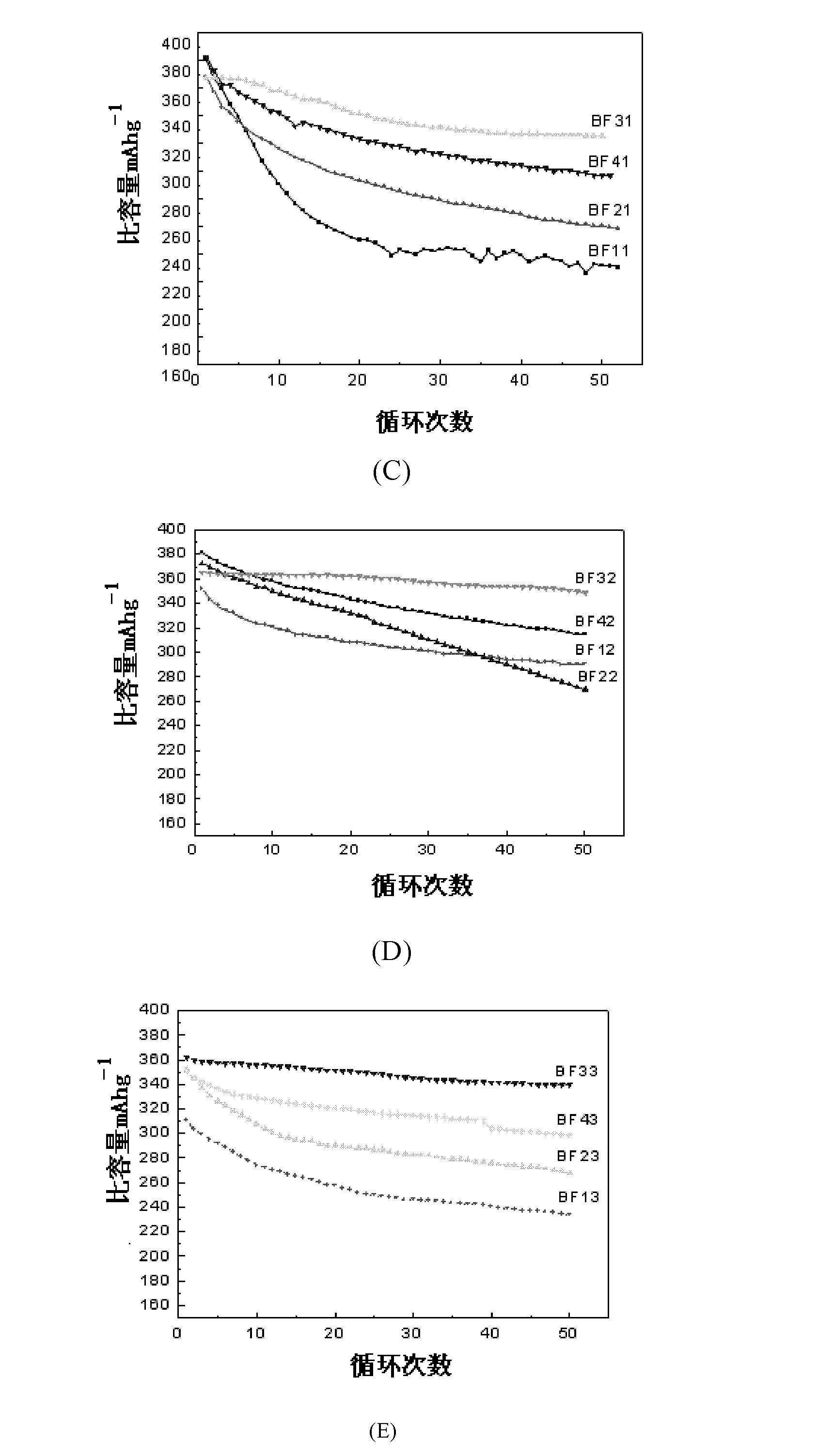

[0078] Preparation of example 2 composite modified material

[0079] Prepare asphalt surface modification solvents with different mass concentrations first, and then slowly add oxidized natural graphite with the best performance to the solvent after the asphalt is completely dissolved in the organic solvent. In the process of adding, a few drops of ethanol can be added to the solution to weaken the surface tension of graphite, so that the asphalt and natural graphite can be mixed evenly; then the graphite-asphalt mixed solution is stirred for several hours, and then the mixed solution is removed and placed in a dry place. Drying in the box; the graphite-pitch mixed solution treated above is dried, sieved, and high-temperature sintered to prepare a negative electrode material for lithium-ion batteries, and put into a sealed bag for later use. The specific preparation process of composite modified materials:

[0080] 1. First add a certain amount of carbon disulfide and other o...

example 3

[0084] Example 3 Making a battery

[0085] The graphite obtained by the above method of composite modification is used as an active material, and the process for further preparing lithium-ion battery electrode materials is as follows:

[0086] (1) Provide the chemical reagents used

[0087] 63% concentrated nitric acid (analytical grade), asphalt, carboxymethyl cellulose (CMC), lithium cobaltate (LiCoO 2 ), polyvinylidene fluoride (PVDF), ethylene oxide, N-methylpyrrolidone (NMP), acetylene black (AB), styrene-butadiene rubber (SBR), super conductive carbon black BP-2000, the electrolyte is South Korea's Samsung The company's production and diaphragm are Celgard2400 microporous films.

[0088] (2) Preparation process of negative electrode material

[0089] Dissolve the mixed preparation of styrene-butadiene rubber (SBR) and carboxymethyl cellulose (CMC) (the proportion of SBR and CMC is 2.5:1.5) in distilled water, and make a viscose with a small amount of ethylene oxide af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com