Silicon-carbon composite material with nano micropores and preparation method as well as application thereof

A silicon-carbon composite material, micro-porosity technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of silicon expansion that cannot be completely solved, the carbon matrix does not really play a stable structure, etc. problems, to achieve the effect of improving electrochemical performance, improving lithium storage capacity, and suppressing shortcomings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

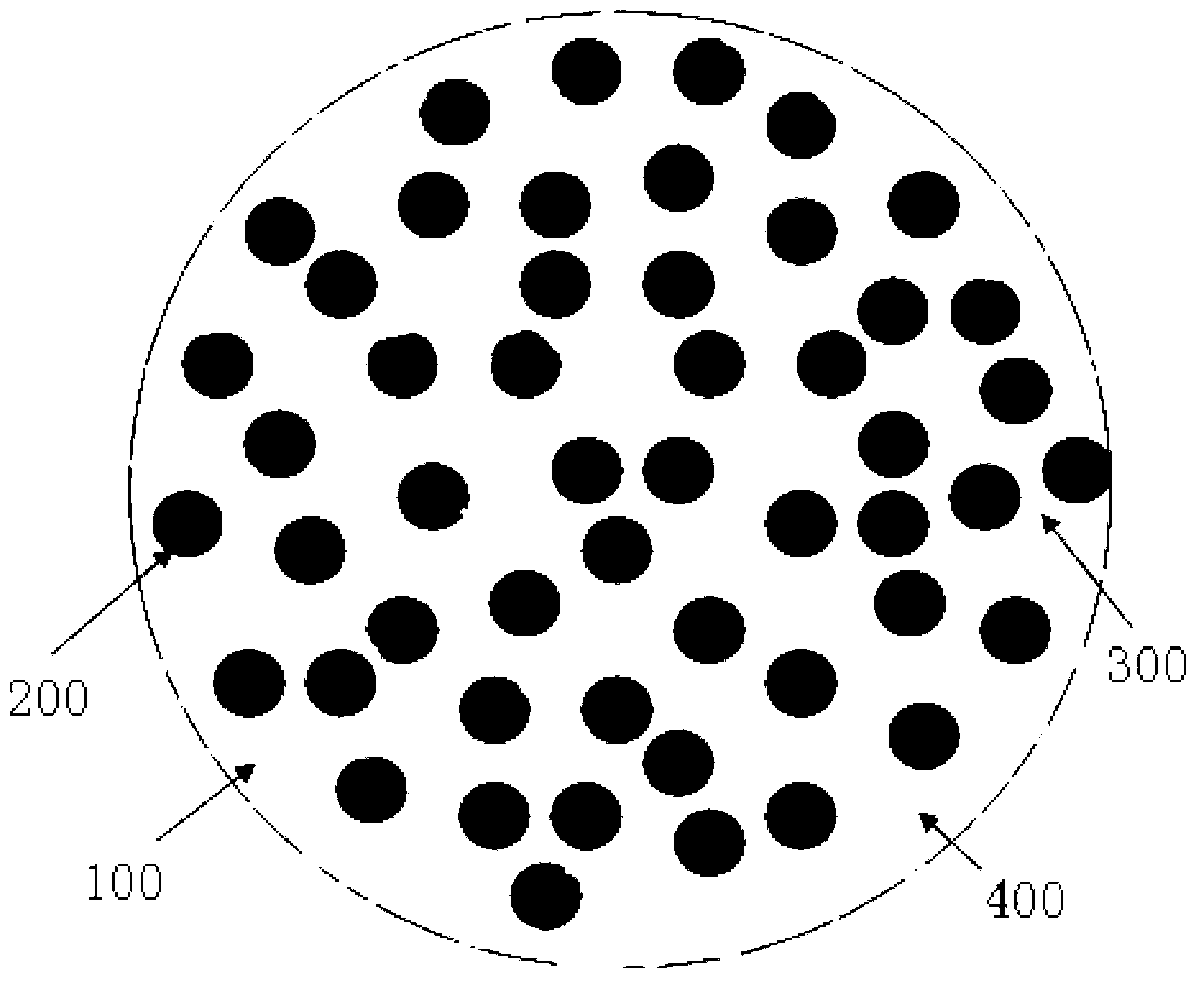

[0029] This embodiment also provides a method for preparing a silicon-carbon composite material with a nanovoid structure, comprising the following steps:

[0030]Step 1: Prepare polyacrylonitrile spinning (PAN) silk solution containing nano-silicon particles and polymer pore-forming agents. The specific steps are as follows: Weigh a certain amount of PAN powder, add it to a certain amount of organic solvent dimethylformamide (DMF), stir and dissolve at 65°C, and prepare a DMF solution of PAN with a mass fraction of 6-15wt%; Taking the quality of PAN as a benchmark, weigh the nano-Si particles that are 1:50-1:1 with the mass ratio of PAN and the polymer pore former ( Polymer-based Pore-Maker, abbreviated as PPM), added to the DMF solution of PAN, continued to stir at 65°C for more than 24 hours, and ultrasonically dispersed for more than 1 hour to obtain a mixture of PAN-Si-PPM in the organic solvent DMF . Among them, the molecular weight M of PAN w It is preferably 100,000...

Embodiment 1

[0057] Compared with Comparative Example 1.

[0058] Step 1: Preparation of polyacrylonitrile spinning solution. Weigh 9g molecular weight M w =150000 PAN powder, added to 96mL of DMF, stirred at 65°C for 24h to dissolve, and prepared a PAN-DMF solution with a mass fraction of 9%; weighed 2.25g of nano-silicon particles with an average particle size of 30-50nm and added them to PAN solution, while adding 4g of PMMA (M w =120000) into the solution, continue stirring at 65°C for 24h, and ultrasonically disperse for 1h to obtain a co-dispersion system of PAN-Si-PMMA in DMF, which will be used for electrospinning.

[0059] The second step: electrospinning to prepare PAN nanofibers doped with Si and PMMA. The electrospinning conditions were the same as the second step in Comparative Example 1 to obtain PAN-Si-PMMA composite nanofibers.

[0060] The third step: oxidation treatment of PAN-Si-PMMA composite nanofibers. The oxidation treatment conditions were the same as in the th...

Embodiment 2

[0065] Compared with Comparative Example 1.

[0066] Step 1: Preparation of polyacrylonitrile spinning solution. Weigh 9g molecular weight M w =150000 PAN powder, added to 96mL of DMF, stirred at 65°C for 24h to dissolve, and prepared a PAN-DMF solution with a mass fraction of 9%; weighed 2.25g of nano-silicon particles with an average particle size of 30-50nm and added them to PAN solution, while adding 4g of PVC (M w =100000) into the solution, continue stirring at 65°C for 24h, and ultrasonically disperse for 1h to obtain a co-dispersion system of PAN-Si-PVC in DMF, which will be used for electrospinning.

[0067] The second step: electrospinning to prepare PAN nanofibers doped with Si and PVC. The electrospinning conditions were the same as the second step in Comparative Example 1 to obtain PAN-Si-PVC composite nanofibers.

[0068] The third step: oxidation treatment of PAN-Si-PVC composite nanofibers. The oxidation treatment conditions were the same as the third step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com