Composite martial for lithium battery and button battery prepared from composite martial

A composite material, button battery technology, applied in nanotechnology for materials and surface science, battery electrodes, lithium batteries, etc. problem, to achieve the effect of improving lithium storage capacity and good electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Graphite oxide (GO) was prepared by improved Hummers’, and 120 mg of graphite oxide was dissolved in distilled water, and ultrasonically dispersed (700 W, 2 h) to obtain a graphite oxide solution (1 mg·mL -1 ), denoted as solution A. Weigh 5g dicyandiamide, 504mg thiourea, 240mg SnCl 2 2H 2 O was dissolved in solution A completely under stirring at room temperature; the mixed solution was transferred to a hydrothermal kettle and heated at 150°C for 12 hours, and naturally cooled to room temperature after the reaction was completed. The hydrothermal reaction product was washed several times with distilled water and then dried at 70 °C. After drying, the sample was calcined at 500 °C for 2 h under a nitrogen atmosphere to obtain SnO 2 -S / N-GNs composites. Using the same method as above, prepare respectively without adding dicyandiamide or thiourea or SnCl 2 2H 2 Composites of O and thiourea, labeled as SnO 2 / GNs, SnO 2 / N-GNs, N-GNs.

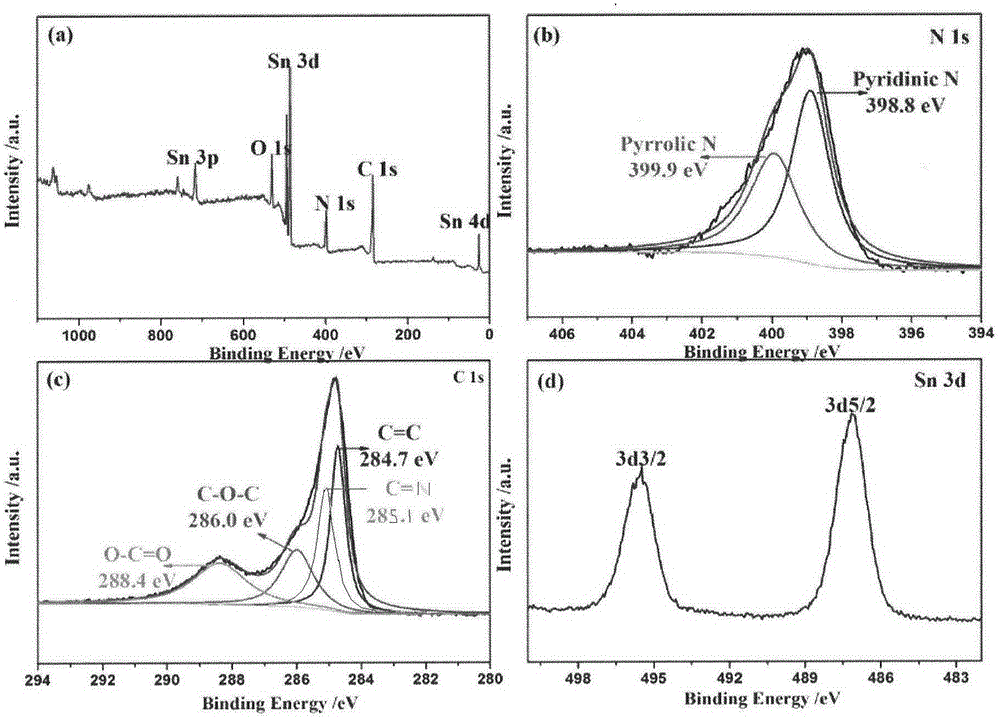

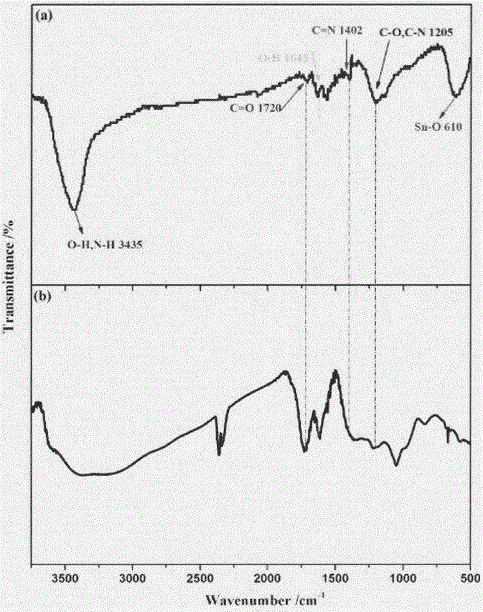

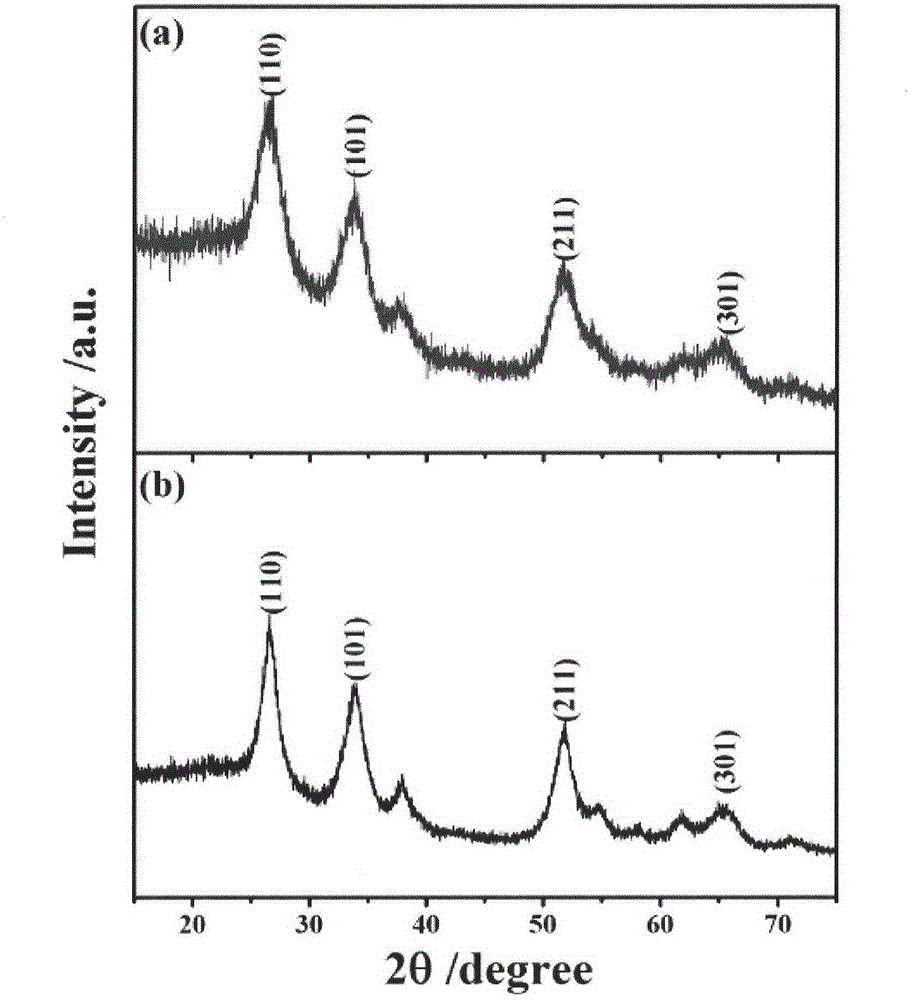

[0031] Analysis and charact...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge specific capacity | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com