Electrochemical energy storage device and preparation method hereof

An electrochemical and energy storage technology, applied in the manufacture of electrochemical generators, electrical components, electrolyte batteries, etc., can solve the problems of difficult blending of metal lithium and anode, poor cycle performance, lithium evolution in batteries, etc. Effects of first efficiency, improved cycle performance, and increased lithium storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

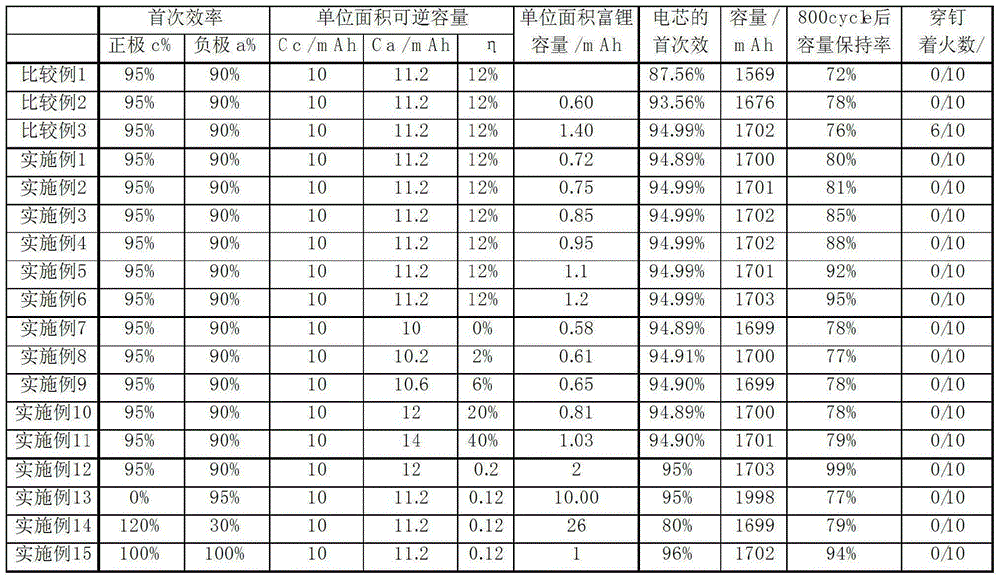

Embodiment 1

[0040] The difference with Comparative Example 2 is that this embodiment includes the following steps:

[0041] Negative electrode sheet preparation: choose graphite with an initial efficiency of 90% as the negative electrode active material, stir it with conductive agent, adhesive and solvent to obtain negative electrode slurry, and then apply it. The coating weight is converted according to the capacity per unit area of 11.2mAh. Afterwards, cold pressing, slitting, welding, and after drying, lithium powder is used as the lithium source, which is evenly dispersed on the surface of the negative electrode coating, and the lithium-rich capacity per unit area is 0.72mAh (that is, Ca×(1-a%) / a%-Cc ×(1-c%) / c%), and then the lithium powder particles are closely combined with the negative electrode coating by rolling, so as to obtain a lithium-enriched negative electrode sheet for use.

[0042] The rest are the same as Comparative Example 2, and will not be repeated here.

Embodiment 2

[0044] The difference with Comparative Example 2 is that this embodiment includes the following steps:

[0045] Negative electrode sheet preparation: choose graphite with an initial efficiency of 90% as the negative electrode active material, stir it with conductive agent, adhesive and solvent to obtain negative electrode slurry, and then apply it. The coating weight is converted according to the capacity per unit area of 11.2mAh. Afterwards, cold pressing, slitting, welding, and after drying, lithium powder is used as the lithium source, which is evenly dispersed on the surface of the negative electrode coating. The lithium-rich capacity per unit area is 0.75mAh, and then the lithium powder particles are tightly combined with the negative electrode coating by rolling , so as to obtain the lithium-enriched negative electrode sheet for use.

[0046] Cell preparation: Wind the above-mentioned negative electrode sheet, the above-mentioned dried positive electrode sheet, and the...

Embodiment 3

[0049] The difference with Comparative Example 2 is that this embodiment includes the following steps:

[0050] Negative electrode sheet preparation: choose graphite with an initial efficiency of 90% as the negative electrode active material, stir it with conductive agent, adhesive and solvent to obtain negative electrode slurry, and then apply it. The coating weight is converted according to the capacity per unit area of 11.2mAh. Afterwards, cold pressing, slitting, welding, and after drying, lithium powder is used as the lithium source, which is evenly dispersed on the surface of the negative electrode coating. The lithium-rich capacity per unit area is 0.85mAh, and then the lithium powder particles are tightly combined with the negative electrode coating by rolling , so as to obtain the lithium-enriched negative electrode sheet for use.

[0051] Cell preparation: Wind the above-mentioned negative electrode sheet, the above-mentioned dried positive electrode sheet, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com