Metallic 1T molybdenum disulfide nano-sheet array as well as preparation method and application thereof

A technology of nanosheet array and molybdenum disulfide, applied in the direction of molybdenum sulfide, nanotechnology, nanotechnology, etc., can solve the problems of unfavorable large-scale preparation and commercial application, high cost, and high equipment requirements, and achieve low cost and simple steps , Improve the effect of wetting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a method for preparing a metallic 1T molybdenum disulfide nanosheet array, comprising the following steps:

[0027] heat-treating the substrate to obtain a functionalized substrate;

[0028] The functionalized substrate, molybdate, and sulfur-containing compound were solvothermally reacted in a solvent to obtain metallic 1T molybdenum disulfide nanosheet arrays.

[0029] The substrate is heat-treated to obtain a functionalized substrate. In the present invention, the base is preferably carbon cloth, carbon paper and nickel foam; the present invention has no special requirements on the shape and area of the base, and the shape and area of the base can be set according to actual needs; the present invention has no special requirements on the shape and area of the base; There is no special requirement for the source of the material, and a substrate well known to those skilled in the art can be used, such as commercially available carbon cloth,...

Embodiment 1

[0044] Cut the carbon cloth (CFC) into an area of 1.13cm 2 The discs were ultrasonically washed with acetone, ethanol, and water for 15 min, and then dried;

[0045] Calcining the dried carbon cloth at 450°C in air for 1 hour to obtain functionalized carbon cloth;

[0046] Dissolve 0.5 mol of sodium molybdate dihydrate and 1.25 mol of L-cysteine in a mixed solvent of 50 mL of water and DMF (the volume ratio of water and DMF is 1:1.5), and stir for 30 min to dissolve;

[0047] Add the obtained reaction solution into a polytetrafluoroethylene liner with a volume of 80mL, put a piece of functionalized carbon cloth disc in the liner, transfer it to a hydrothermal reaction kettle and keep it warm at 200°C for 12h, then cool naturally, separate , washing, and drying to obtain a carbon cloth covered with metallic 1T phase molybdenum disulfide nanosheet arrays.

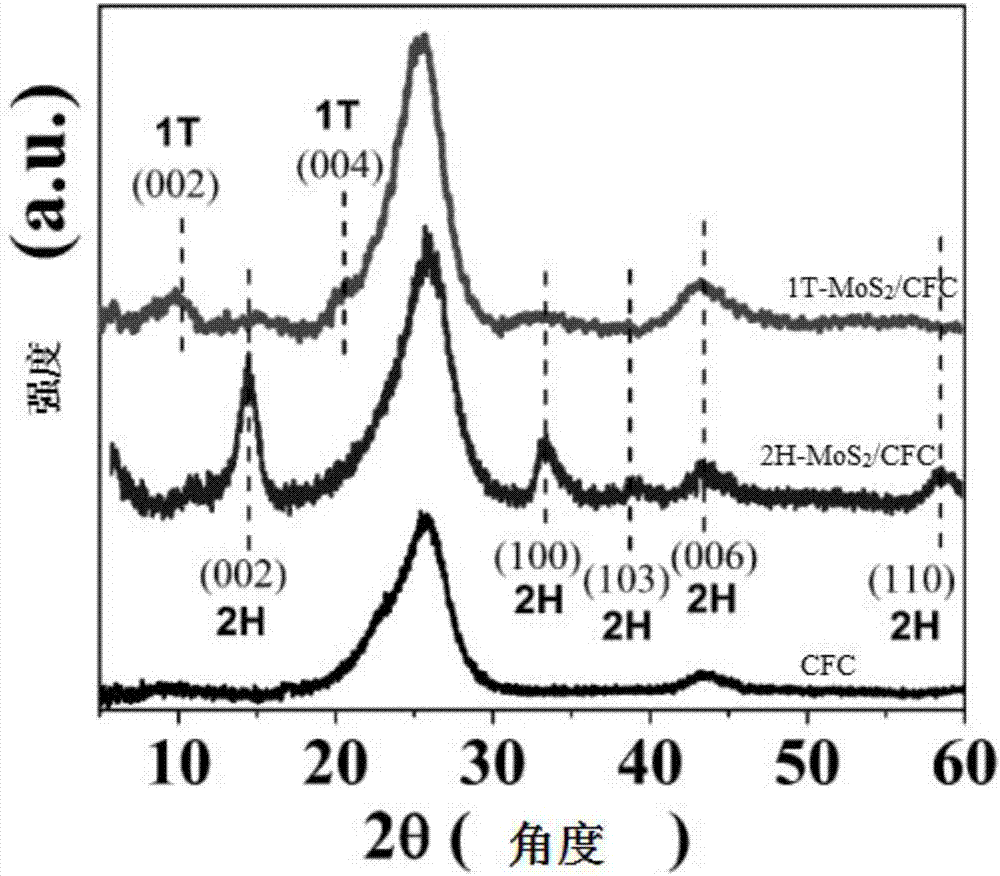

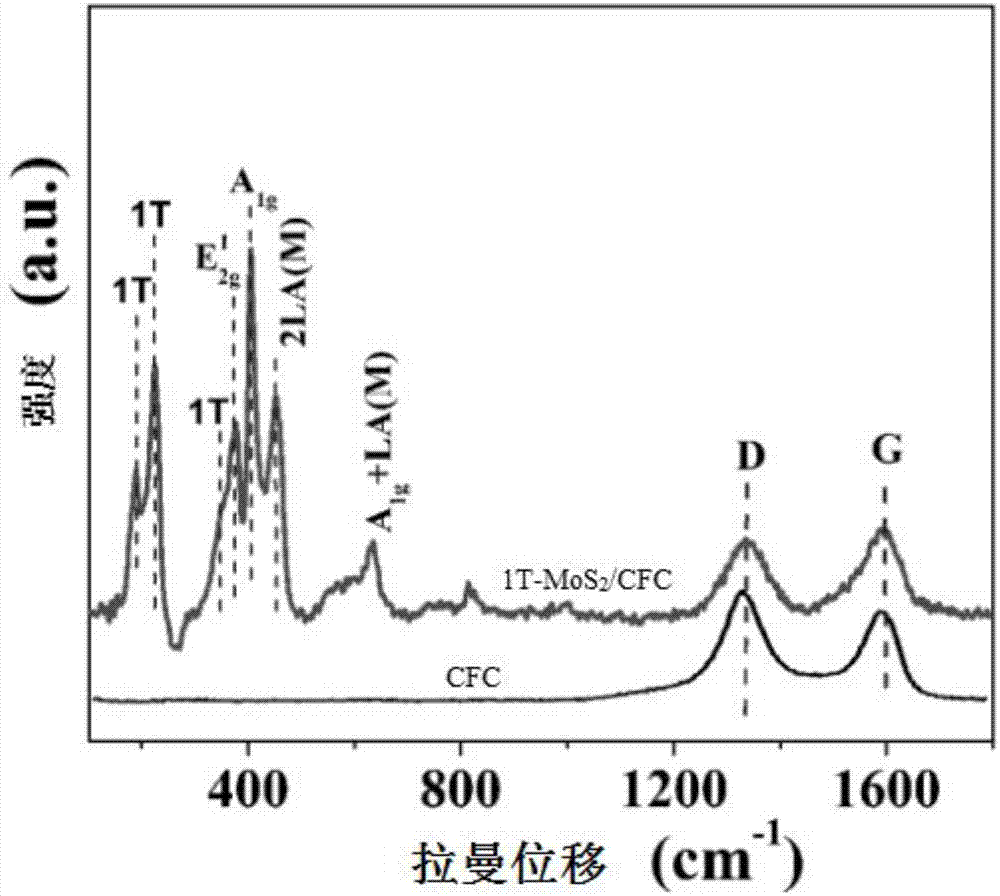

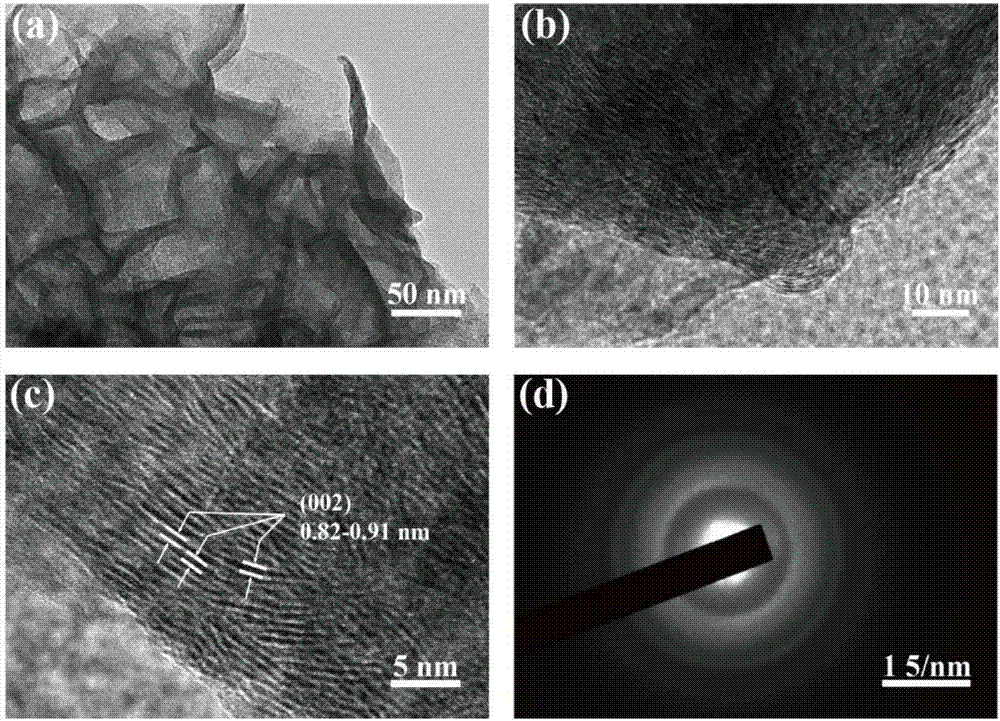

[0048] Carbon cloth (CFC), metallic 1T phase molybdenum disulfide nanosheet arrays (1T-MoS) grown on the surface of c...

Embodiment 2

[0052] Cut the nickel foam into an area of 1.13cm 2 The discs were ultrasonically washed with acetone, ethanol, and water for 15 min, and then dried;

[0053] The dried carbon cloth was calcined in air at 400°C for 1.5 hours to obtain functionalized nickel foam;

[0054] Dissolve 0.5mol of sodium molybdate dihydrate and 1.0mol of L-cysteine in 30mL of water, stir for 30min to dissolve;

[0055] The resulting reaction solution was added to a polytetrafluoroethylene liner with a volume of 80 mL, and a piece of functionalized nickel foam disc was placed in the liner, transferred to a hydrothermal reaction kettle and kept at 180°C for 24 hours, then cooled naturally, and separated , washing, and drying to obtain foamed nickel covered with metallic 1T phase molybdenum disulfide nanosheet arrays.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com