Method for preparing three-dimensional nitrogen-doped graphene/CoOx composite material

A nitrogen-doped graphene and composite material technology is applied in the field of preparation of three-dimensional nitrogen-doped graphene/CoOx composite nanomaterials, which can solve problems such as cumbersome steps, and achieve the advantages of simple preparation method, good rate performance, and excellent electrical conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

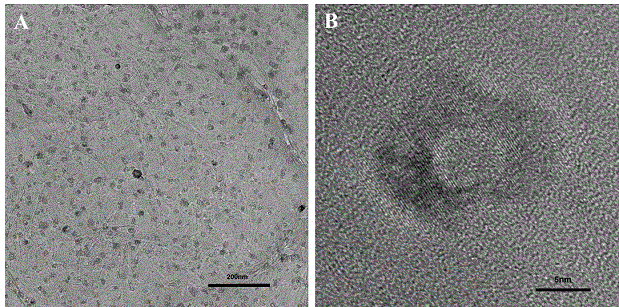

[0028] Nitrogen-doped graphene / CoO x The preparation steps of the composite material are as follows:

[0029] A. Preparation of Graphene Oxide (GO)

[0030] a. Weigh 10g of graphite powder and 7.5g of sodium nitrate in a 2L round bottom beaker, and mechanically stir vigorously. Slowly add 300mL of concentrated sulfuric acid, and after stirring for 0.5h, slowly add 40g of potassium permanganate (completely added in 2 hours). When the magnetic stirrer was stirred until the next day, the mixture in the flask turned brown and had a thick character, and then changed to a mechanical stirrer for about five days.

[0031] b. Slowly add 1L of deionized water into the beaker. Since this process will release a lot of heat, the speed must be controlled when the dilution is first started. After dilution, the mixture turns into a tan liquid. Slowly add 60ml of 30% hydrogen peroxide while stirring to neutralize the unreacted potassium permanganate. At the same time, a large number of bubb...

Embodiment 2

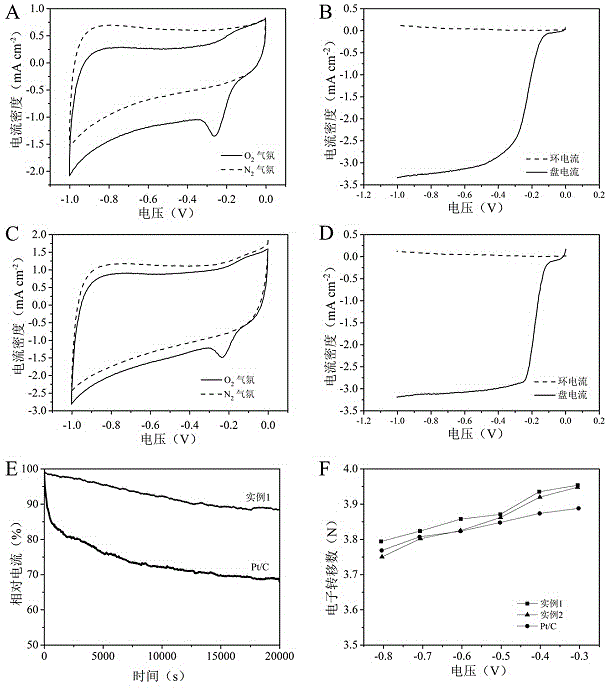

[0040] The difference between this example and Example 1 is: the surfactant is F127, and the addition amount is 1mg / ml; the temperature is raised to 600°C at a rate of 2°C / min under a nitrogen atmosphere; the material is used as a cathode catalyst for the fuel cell oxygen reduction reaction.

Embodiment 3

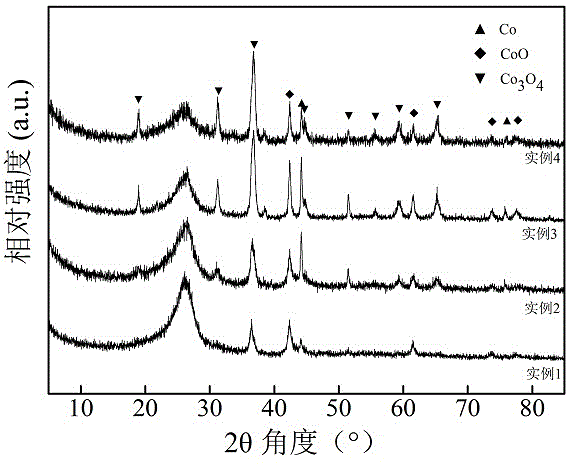

[0042] e. Heat up the 3D cobalt phthalocyanine / surfactant CTAB / graphene airgel obtained in B (c) above to 800°C at a rate of 2°C / min in a nitrogen atmosphere, keep it for 2h, and wait for the temperature to drop to 400°C ℃, stop the nitrogen flow, change to the air, keep the sample for 20 minutes, and then cool the sample rapidly to obtain a three-dimensional nitrogen-doped graphene / CoO x nanocomposites, and the obtained cobalt is Co 3 o 4 as the main form (3D nitrogen-doped graphene / CoO x -2); The material can be used as a negative electrode catalyst for lithium-ion batteries.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com