Preparation method of porous carbon material and application of porous carbon material as electrode material

A porous carbon and microporous technology, which can be used in the preparation/purification of carbon, battery electrodes, circuits, etc., can solve problems such as limited application, and achieve the effect of good practical application value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Dissolve 1g of phenolic resin, 3g of magnesium-aluminum hydrotalcite, and 0.35g of curing agent hexamethylenetetramine in absolute ethanol, mix well after dissolution, and stir naturally until the ethanol is completely volatilized. The mixture was cured in a vacuum oven at 150°C for 4 hours, and then the cured product was placed in a carbonization furnace and heated to 600°C for 6 hours under nitrogen protection. The carbonized product is sequentially treated with excess hydrochloric acid and KOH solution, then centrifuged, washed with deionized water until neutral, and dried to obtain the target porous carbon material.

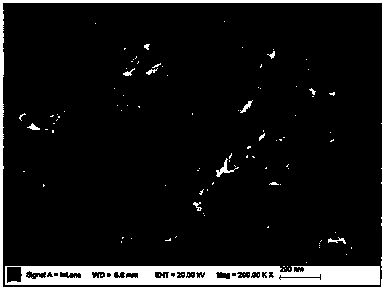

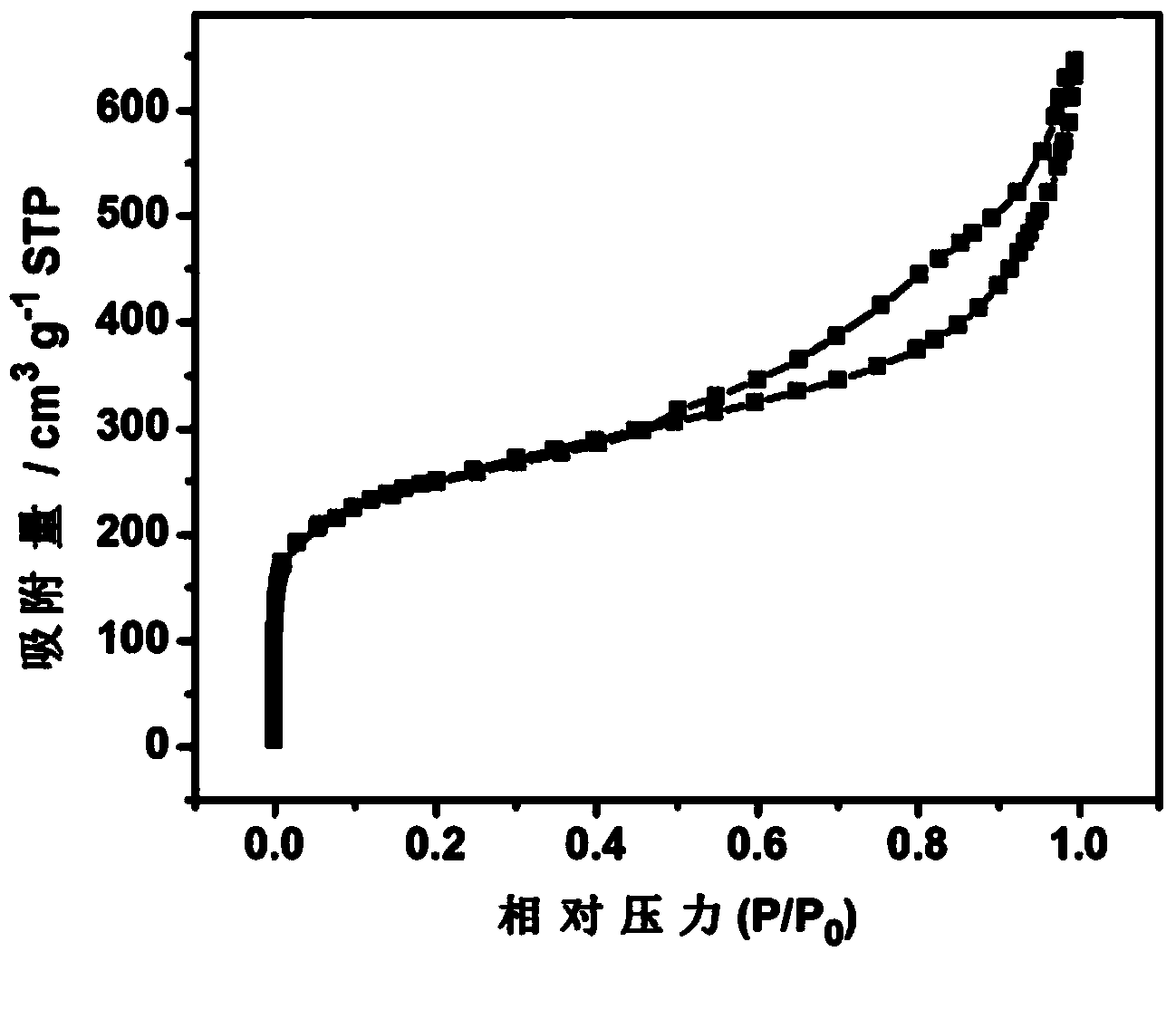

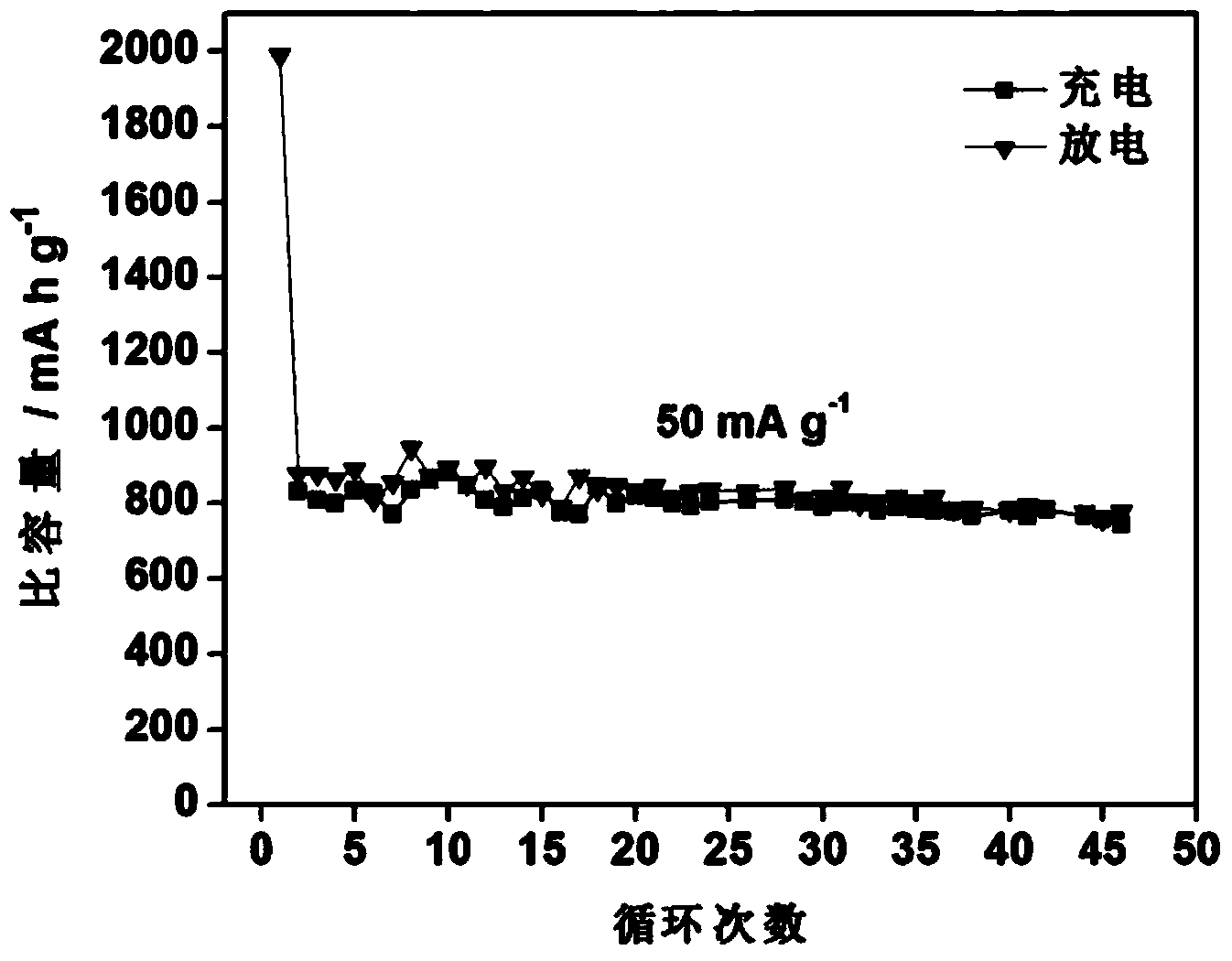

[0029] Such as figure 1 As shown, the porous carbon material is a loose block with a slit-like pore structure. Its nitrogen isotherm adsorption curve presents an obvious hysteresis loop, indicating that a large number of mesopores are formed ( figure 2 ). The total specific surface area of the porous carbon material is 887 m 2 / g, of which the ...

Embodiment 2

[0033] The operating conditions are the same as in Example 1, except that the mass of the hydrotalcite is changed to 1 g, and the carbonization condition is 800° C. for 6 hours.

[0034] The obtained porous carbon material has a specific surface area of 503 m 2 / g. The electrochemical test was carried out by the same method as in Example 1, and the results showed that the reversible capacity reached 652 mAh / g at a current density of 50 mA / g, and the capacity remained at 503 mAh / g after 50 cycles. Under high current, the reversible capacity is 214 mAh / g when the current density is 1 A / g.

Embodiment 3

[0036] The operating conditions are the same as in Example 1, except that the phenolic resin is changed to sucrose, and the carbonization temperature used is 600° C. for 2 hours.

[0037] The obtained porous carbon has a specific surface area of 780 m 2 / g. The electrochemical test was carried out by the same method as in Example 1, and the results showed that the reversible capacity reached 884 mAh / g at a current density of 50 mA / g, and the capacity remained at 690 mAh / g after 50 cycles. Under high current, the reversible capacity is 513 mAh / g when the current density is 200 mA / g, and the reversible capacity is 285 mAh / g when the current density is 1A / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total specific surface area | aaaaa | aaaaa |

| Micropore specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com