Airplane wheel dismounting and mounting mechanism

A wheel and sliding mechanism technology, applied in tire installation, aircraft parts, wheel assembly and disassembly equipment, etc., to achieve the effect of easy operation and good practical application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

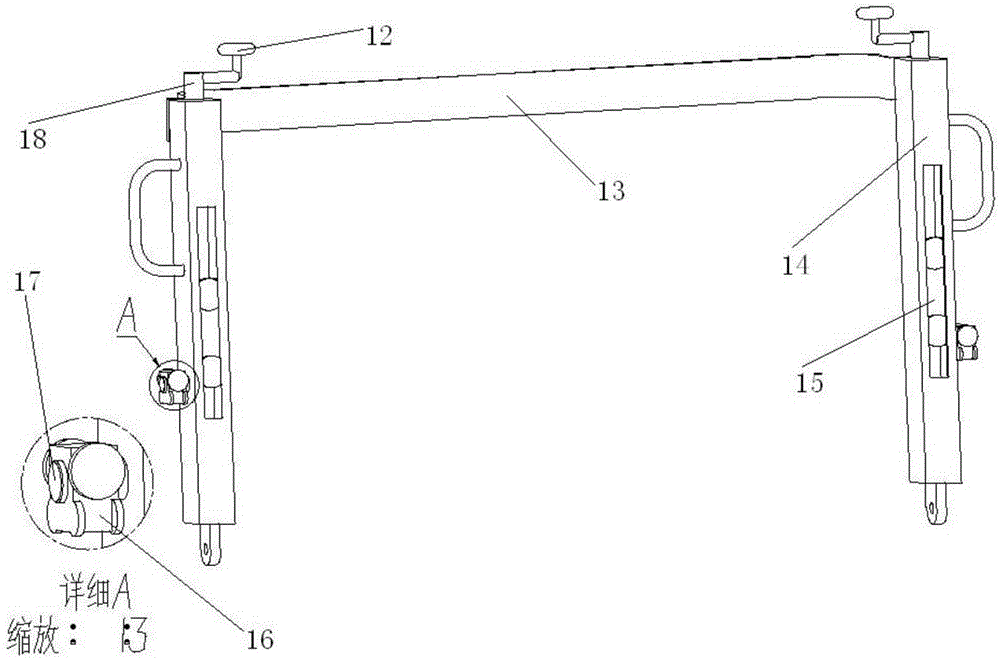

[0012] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

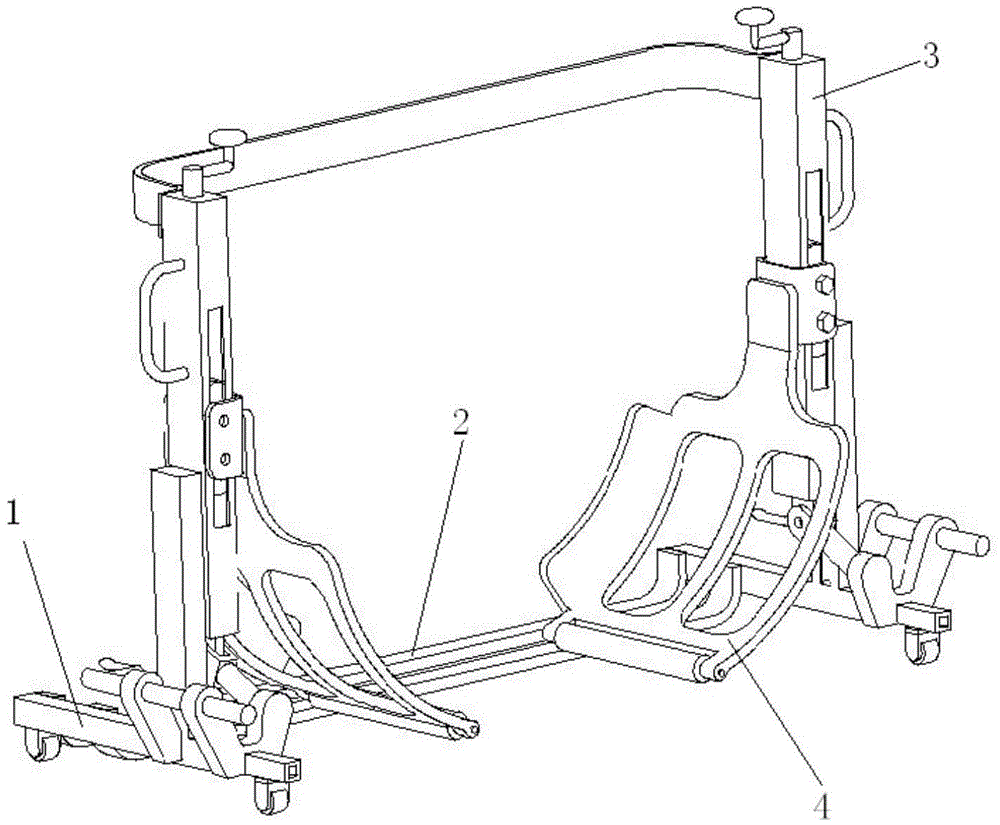

[0013] see figure 1 , A specific embodiment of the present invention mainly includes a left and right lead screw sliding mechanism 1 each, two lower beams 2, a movable frame 3 and a left and right wheel claw mechanism 4 each. The left and right lead screw sliding mechanisms are welded together with the two lower beams to form the frame of the equipment; the lower end of the movable frame is connected to the oblique arms in the left and right lead screw sliding mechanisms through hinge joints, and the slider on the movable frame can be placed in the lead screw sliding mechanism The vertical column slides up and down; the claw mechanism is connected with the nut B in the movable frame through bolts.

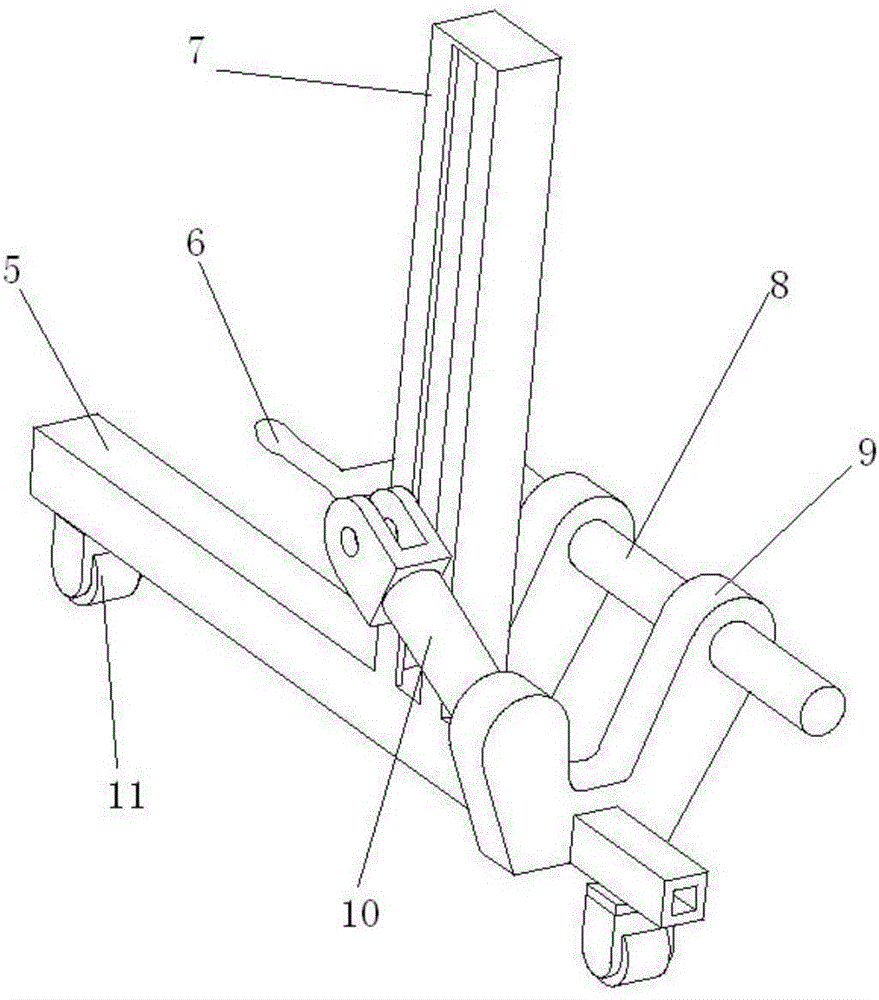

[0014] see figure 2 , the screw sliding mechanism 1 of the equipment is divided into left and right symmetrical parts, mainly including a sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com