Silicon-containing negative electrode of lithium ion battery and preparation method of silicon-containing negative electrode

A technology for lithium-ion batteries and silicon negative electrodes, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of low initial charge and discharge efficiency, and achieve the effects of low cost, simple preparation method, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Weigh 38.2g of natural graphite (average particle size D50=25.2μm) and 1.0g polycrystalline silicon nanoparticles (average particle size D50=0.26μm) into a certain amount of beaker, and slowly mechanically stir for 10 minutes to mix the two powders evenly; Add 40g of carboxymethyl cellulose aqueous dispersion with a concentration of 1.0%, completely wet the surface of the powder particles with a glass rod, and then turn on high-speed mechanical stirring (>1000 rpm); add 0.8g of 50% carboxymethyl cellulose after 30 minutes For the aqueous dispersion of styrene-butadiene rubber, continue high-speed mechanical stirring (>1000 rpm), stop after 10 minutes, and obtain gray-black viscous slurry. After coating the gray-black viscous slurry, dry it at 80°C, and roll it with a double-roller machine to make the compacted density of the overall pole piece reach 1.60-1.75g / cm 3 , that is, the final usable pole piece is obtained.

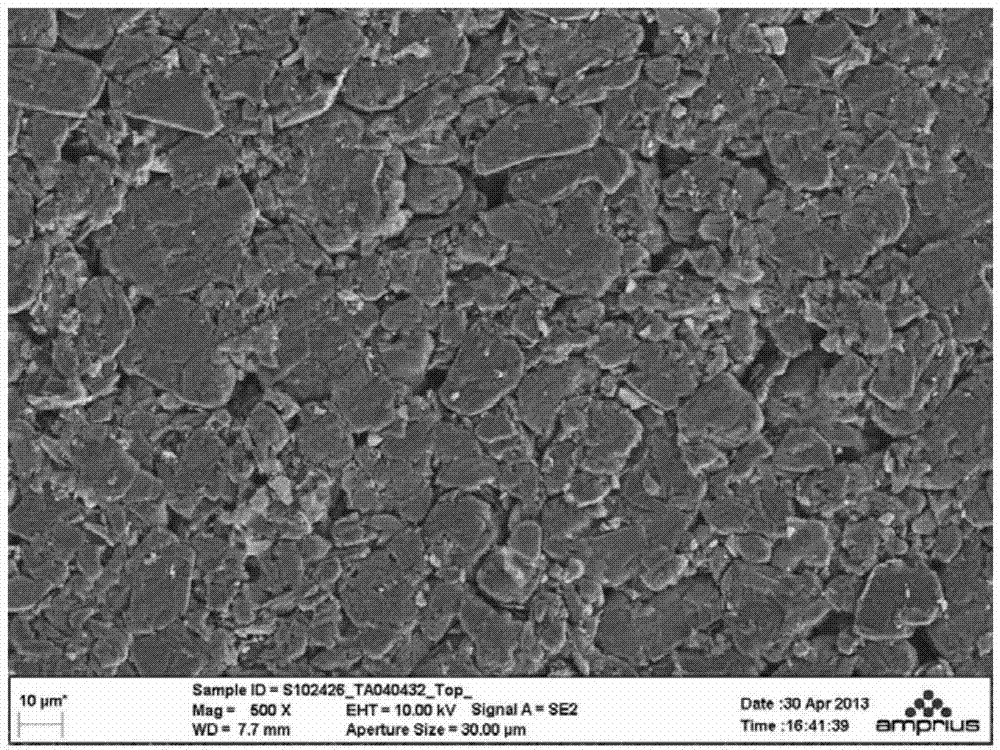

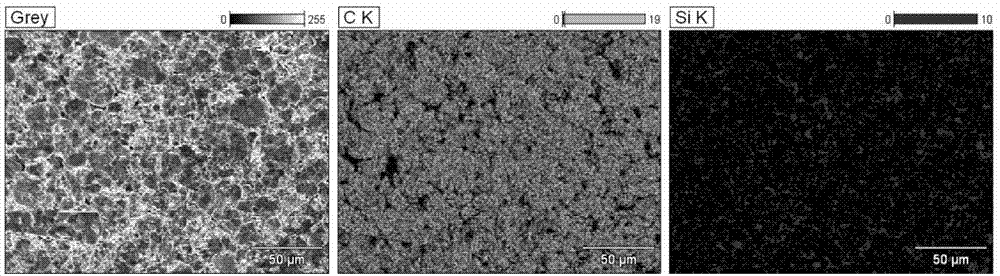

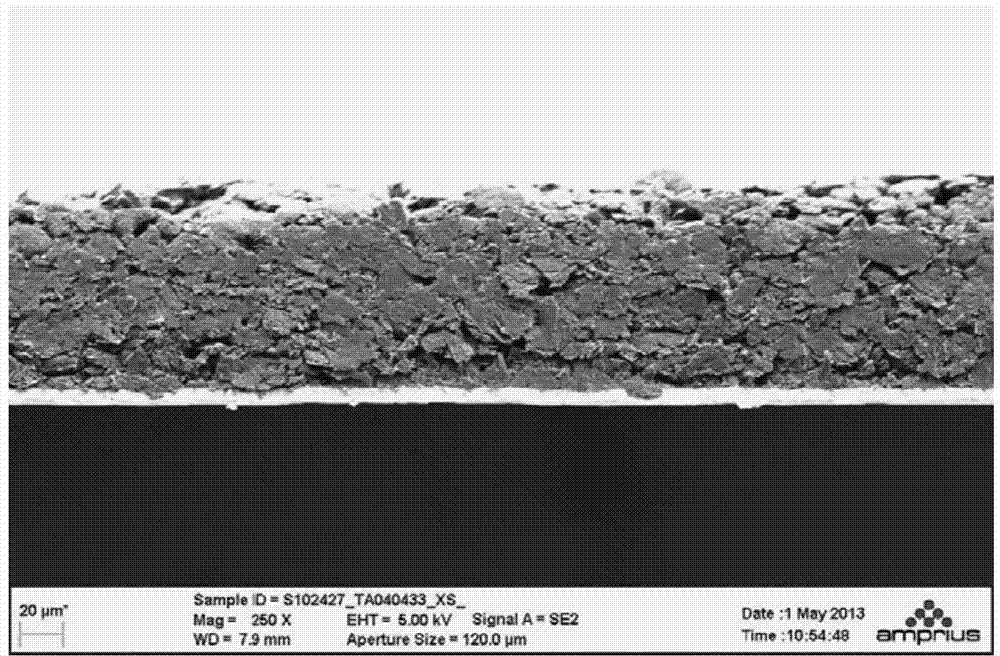

[0041] Scanning electron microscope test: After vac...

Embodiment 2

[0047] Weigh 37.2g of artificial graphite (average particle size D50=22.6μm) and 2.0g polycrystalline silicon nanoparticles (average particle size D50=0.26μm) into a certain amount of beaker, and slowly mechanically stir for 10 minutes to mix the two powders evenly; Add 40g of carboxymethyl cellulose aqueous dispersion with a concentration of 1.0%, completely wet the surface of the powder particles with a glass rod, and then turn on high-speed mechanical stirring (>1000 rpm); add 0.8g of 50% carboxymethyl cellulose after 30 minutes For the aqueous dispersion of styrene-butadiene rubber, continue high-speed mechanical stirring (>1000 rpm), stop after 10 minutes, and obtain gray-black viscous slurry. After coating the gray-black viscous slurry, dry it at 80°C, and roll it with a double-roller machine to make the compacted density of the overall pole piece reach 1.60-1.75g / cm 3 , that is, the final usable pole piece is obtained.

[0048] Electrical performance test results: the ...

Embodiment 3

[0051] Weigh 39.2g surface-modified natural graphite (average particle diameter D50=24.4μm) and 0.2g polysilicon nano-particles (average particle diameter D50=0.26μm) into a certain amount of beaker, and slowly mechanically stir for 10 minutes to make the two Mix the powder evenly; add 40g of carboxymethyl cellulose aqueous dispersion with a concentration of 1.0%, completely wet the surface of the powder particles with a glass rod, and then turn on high-speed mechanical stirring (>1000 rpm); add 0.8g concentration after 30 minutes For 50% styrene-butadiene rubber aqueous dispersion, continue high-speed mechanical stirring (>1000 rpm), stop after 10 minutes, and obtain gray-black viscous slurry. After coating the gray-black viscous slurry, dry it at 80°C, and roll it with a double-roller machine to make the compacted density of the overall pole piece reach 1.60-1.75g / cm 3 , that is, the final usable pole piece is obtained.

[0052] Electrical performance test results: such as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com