Lithium ion battery negative electrode material and preparation method thereof

A technology for lithium ion batteries and negative electrode materials, which is applied in the fields of energy storage materials and lithium ion batteries, can solve the problems of cumbersome steps, high cost, time-consuming and material-consuming processes, and achieves a controllable preparation process, simple preparation method and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

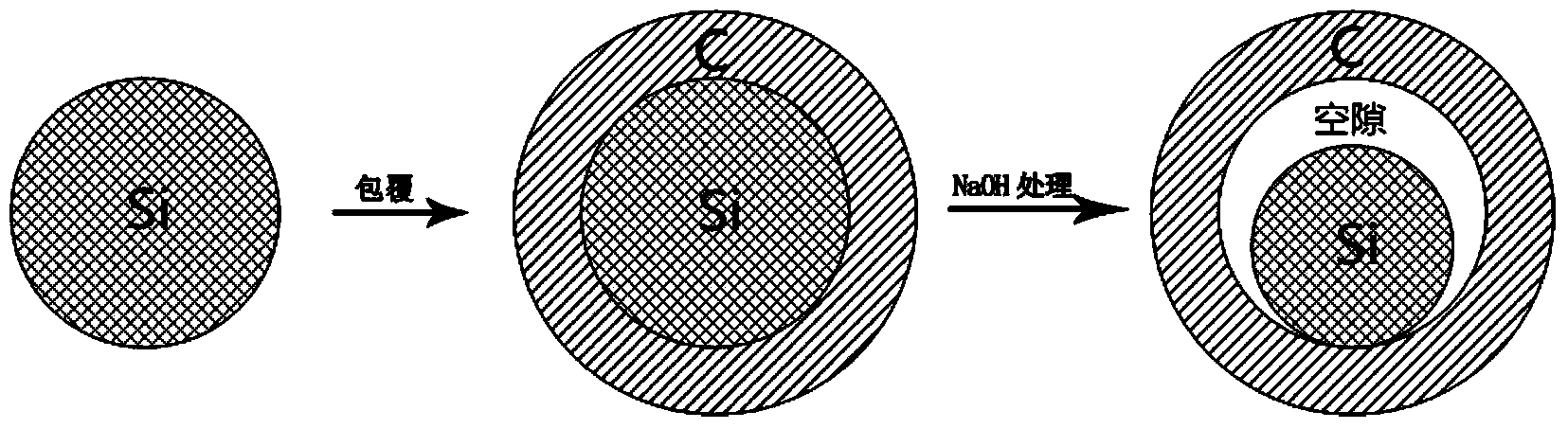

Method used

Image

Examples

Embodiment 1

[0035] (1) Put silicon particles and dopamine with a mass of 0.2 g in a solution containing tris at a concentration of 0.1 mM, and continuously stir and react for 24 hours, then centrifuge and wash the reaction product 3 times with deionized water, Dry at 80° C. for 24 hours in a vacuum to obtain a precursor.

[0036] (2) Calcining the precursor at 800°C for 4 hours in an argon-hydrogen mixed gas atmosphere to obtain carbon-coated silicon particles;

[0037] (3) Put carbon-coated silicon particles in 0.5M NaOH aqueous solution at 60°C for 10 minutes, wash with deionized water three times, and dry at 80°C in vacuum for 24 hours to obtain lithium-ion battery anode materials.

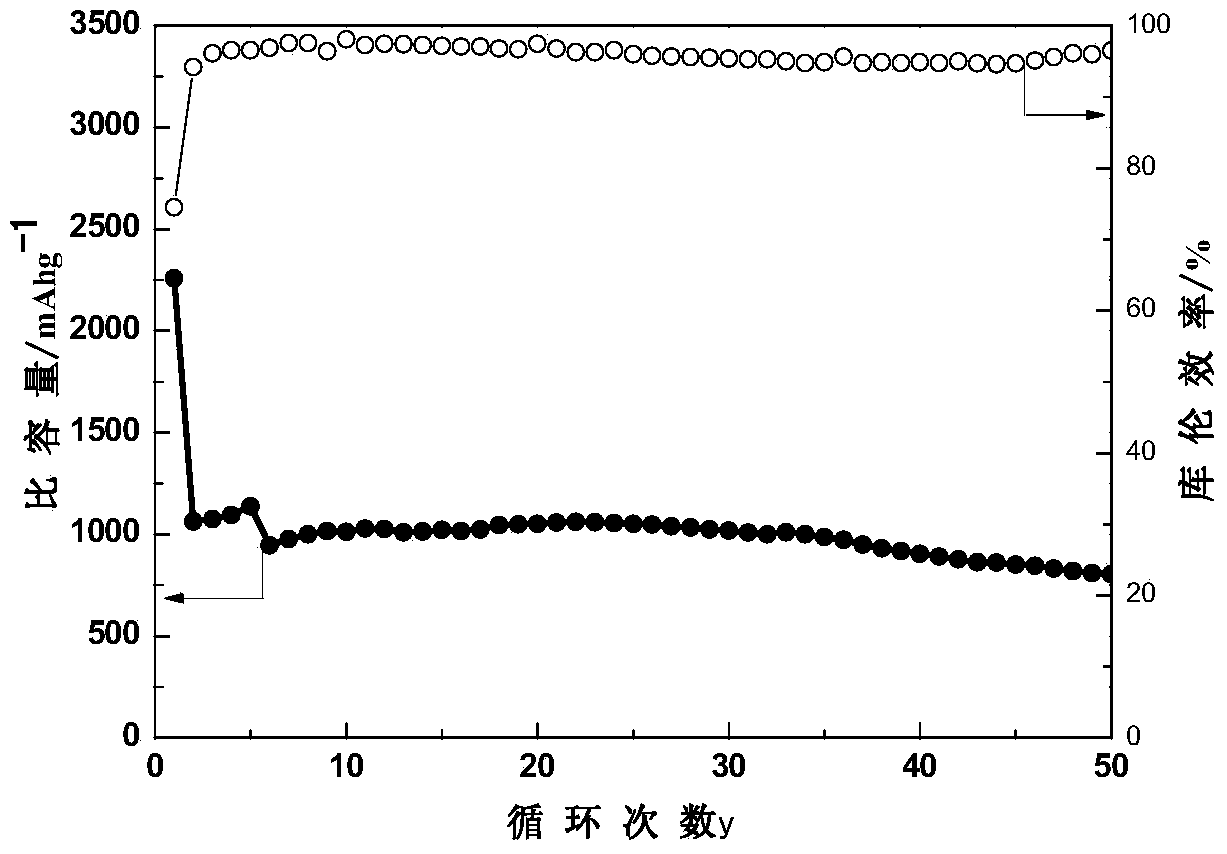

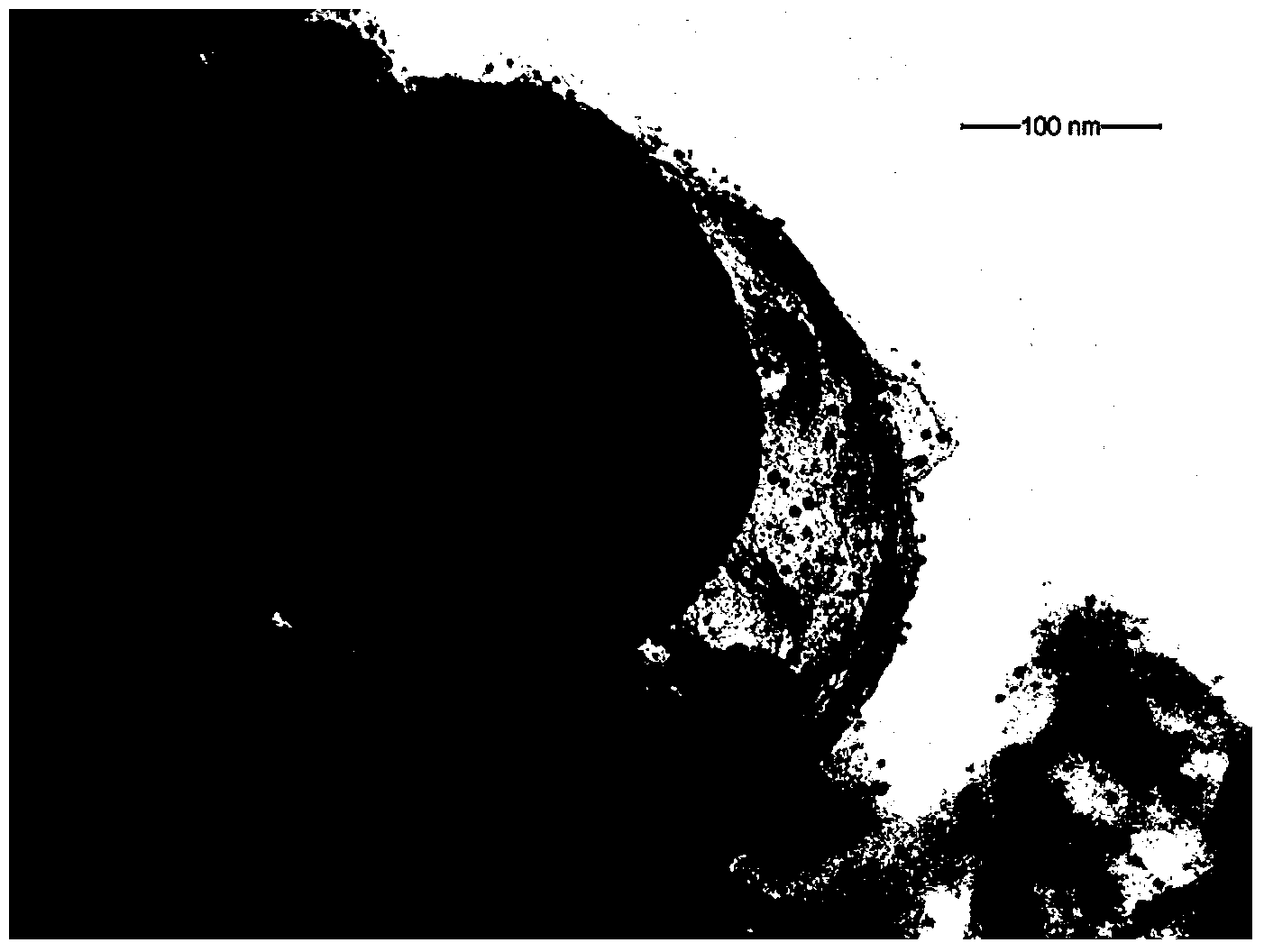

[0038] figure 2 It is the charge-discharge cycle diagram of the negative electrode material obtained in this example. image 3 It is a TEM image. Such as figure 2 It is shown that under 1C rate, charging and discharging in the range of 0.01 ~ 1.5V, the battery can still maintain about 850mAh / g after ...

Embodiment 2

[0040] (1) Put silicon particles and dopamine with a mass of 0.2 g in a solution containing tris at a concentration of 0.1 mM, and continuously stir and react for 12 hours, then centrifuge and wash the reaction product 3 times with deionized water, Dry at 80° C. for 12 hours in a vacuum to obtain a precursor.

[0041] (2) Calcining the precursor at 400°C for 3 hours in an argon atmosphere to obtain carbon-coated silicon particles;

[0042] (3) Put carbon-coated silicon particles in 0.5M KOH aqueous solution at 30°C for 2 minutes, wash with deionized water three times, and dry at 60°C in vacuum for 12 hours to obtain lithium-ion battery negative electrode materials.

[0043] Figure 4 TEM image of the negative electrode material. It can be seen from the TEM image that the void formed by 2-minute etching is not as large as that formed by 10-minute etching.

Embodiment 3

[0045] (1) In the tris solution with a concentration of 0.1mM, put silicon particles and dopamine with a mass of 0.2g, stir for 24 hours and react, then wash the reaction solution with deionized water and centrifuge for 3 times Placed at 80° C. for 24 hours in vacuum to obtain a precursor.

[0046] (2) Calcining the precursor obtained in step (1) at 800°C for 4 hours under the condition of argon-hydrogen mixed gas to obtain carbon-coated silicon particles.

[0047] (3) Put the product obtained in step (2) into a 0.5M NaOH aqueous solution at 80°C for 5 minutes, wash it with deionized water for 3 times, and then dry it in a vacuum oven at 80°C for 24 hours to obtain the negative electrode material for lithium-ion batteries .

[0048] Figure 5 TEM image of the negative electrode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com