Cathode material for lithium-ion battery, preparation method of cathode material and battery

A lithium-ion battery, cathode material technology, applied in battery electrodes, secondary batteries, secondary battery repair/maintenance, etc., can solve the problems of insufficient cycle performance and rate performance, high cost, improve reversible specific capacity, reduce corrosion , the effect of increasing the cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

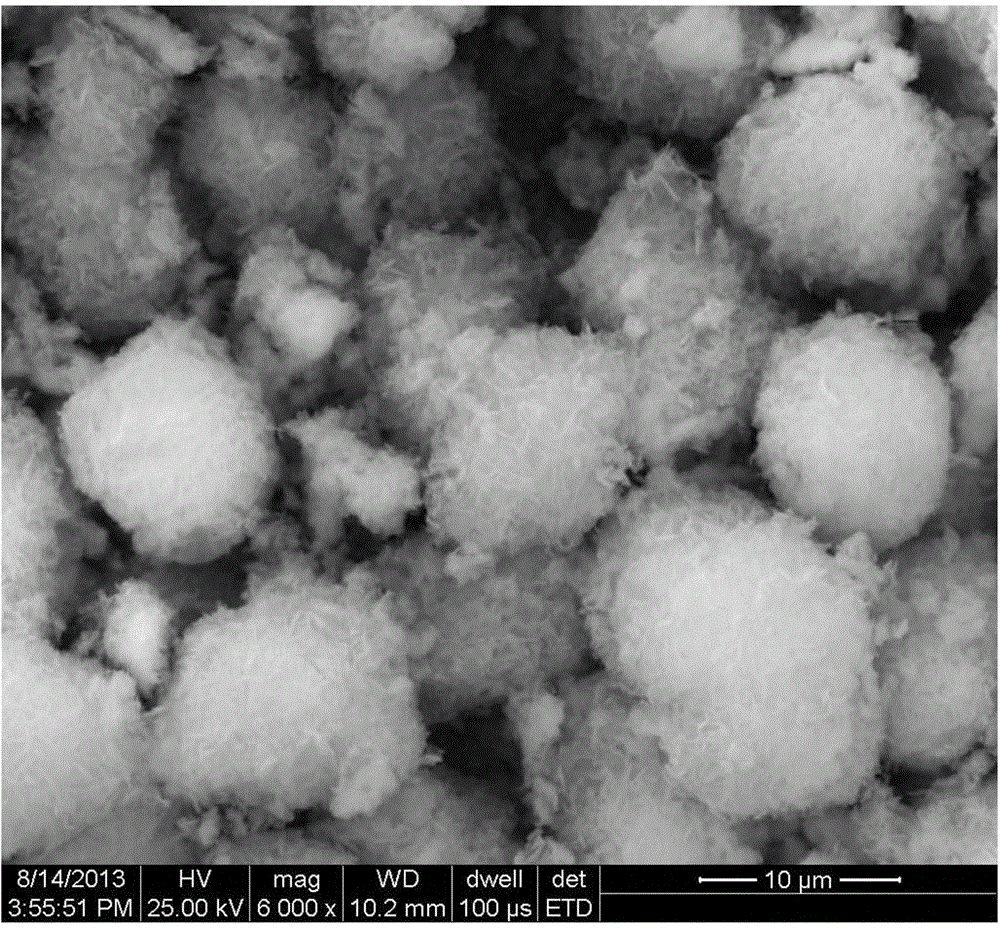

Image

Examples

Embodiment 1

[0042] This embodiment provides a method for preparing a positive electrode material for a lithium-ion battery, comprising the following steps:

[0043] (1) Using nickel sulfate, cobalt sulfate, and manganese sulfate as raw materials, configure the first mixed aqueous solution of the first metal salt according to the ratio of substances Ni: Co: Mn = 0.5: 0.25: 0.25. All metals in the first mixed aqueous solution The total concentration of salt was 3M. Add the first mixed aqueous solution, 10M sodium hydroxide of the first precipitating agent, and 10M ammonia water of the first complexing agent to the 2M ammonia water of the first bottom liquid, and put it in a water bath at 80°C for 24 hours, with a stirring speed of 1000rpm, and the first mixed aqueous solution The first metal salt in the precipitate is precipitated, and the precipitate is filtered, washed and dried to obtain the first precipitate.

[0044] (2) Using nickel sulfate, cobalt sulfate, manganese sulfate, and alu...

Embodiment 2

[0051] This embodiment provides a method for preparing a positive electrode material for a lithium-ion battery, comprising the following steps:

[0052] (1) Using nickel nitrate, cobalt nitrate, and manganese nitrate as raw materials, configure the first mixed aqueous solution of the first metal salt according to the ratio of substances Ni:Co:Mn=0.55:0.2:0.25, and all the metals in the first mixed aqueous solution The total concentration of salt was 1M. Add the first mixed aqueous solution, the first precipitating agent 5M sodium hydroxide, and the first complexing agent 8M ammonium nitrate to the first bottom liquid 1M ammonium nitrate, and put it in a water bath at 60°C for 12h, with a stirring speed of 800rpm, the first The first metal salt in the mixed aqueous solution is precipitated, and the precipitate is filtered, washed and dried to obtain the first precipitate.

[0053] (2) Using nickel nitrate, cobalt nitrate, manganese nitrate, and aluminum nitrate as raw material...

Embodiment 3

[0057] This embodiment provides a method for preparing a positive electrode material for a lithium-ion battery, comprising the following steps:

[0058] (1) Using nickel acetate, cobalt acetate, and manganese acetate as raw materials, configure the first mixed aqueous solution of the first metal salt according to the ratio of substances Ni: Co: Mn = 0.4: 0.3: 0.3, and all metals in the first mixed aqueous solution The total concentration of salt was 0.1M. Add the first mixed aqueous solution, the first precipitant 1M potassium carbonate, and the first complexing agent 6M ammonia water to the ammonia water with a pH value of 9 in the first bottom liquid, and put it in a water bath at 40°C for 6 hours, with a stirring speed of 600rpm. The first metal salt in the mixed aqueous solution is precipitated, and the precipitate is filtered, washed and dried to obtain the first precipitate.

[0059] (2) Using nickel acetate, cobalt acetate, manganese acetate, and aluminum acetate as ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com