Lithium ion battery and anode active material thereof

A positive active material and lithium-ion battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as poor cycle stability, capacity fading, and battery performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

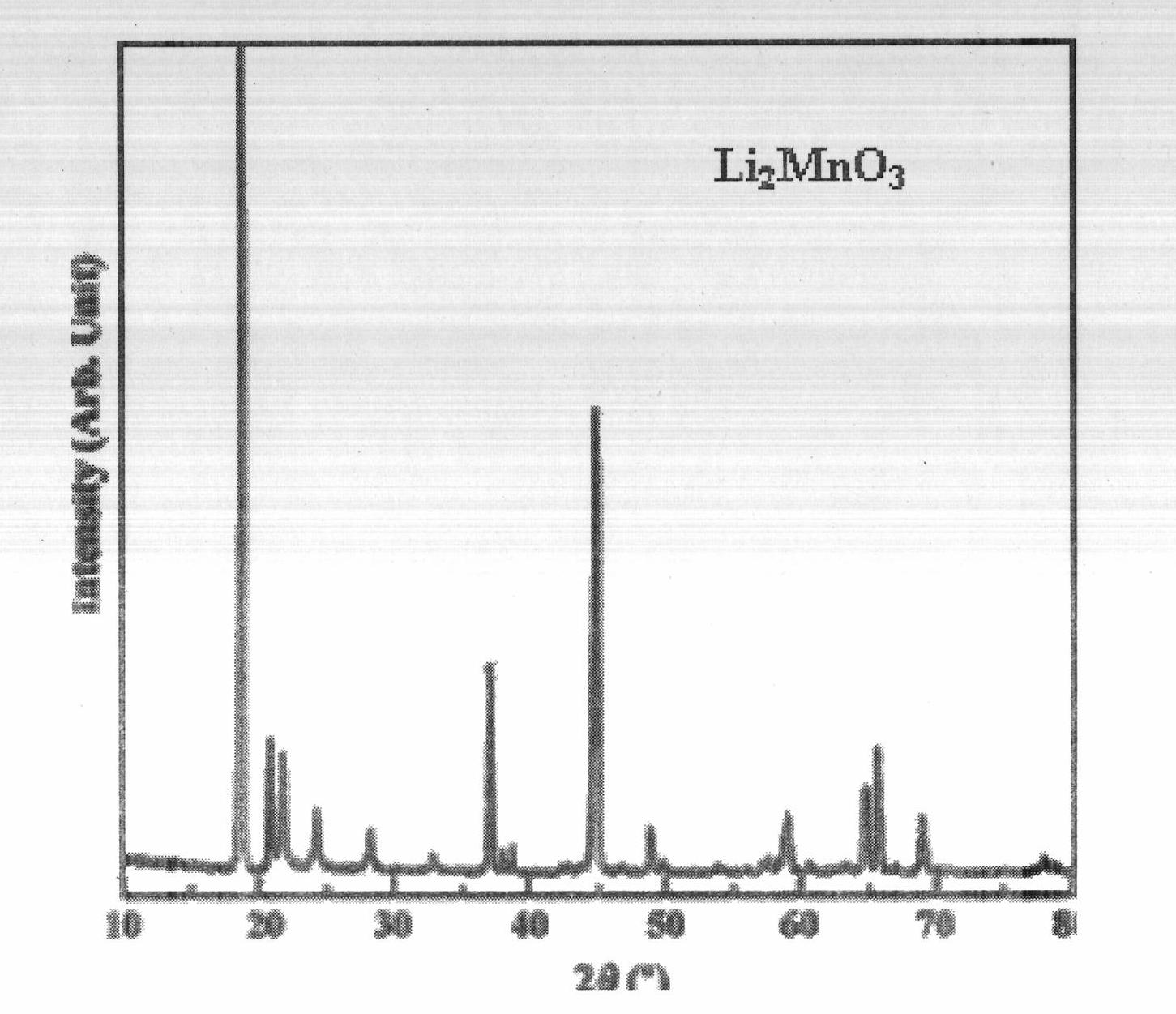

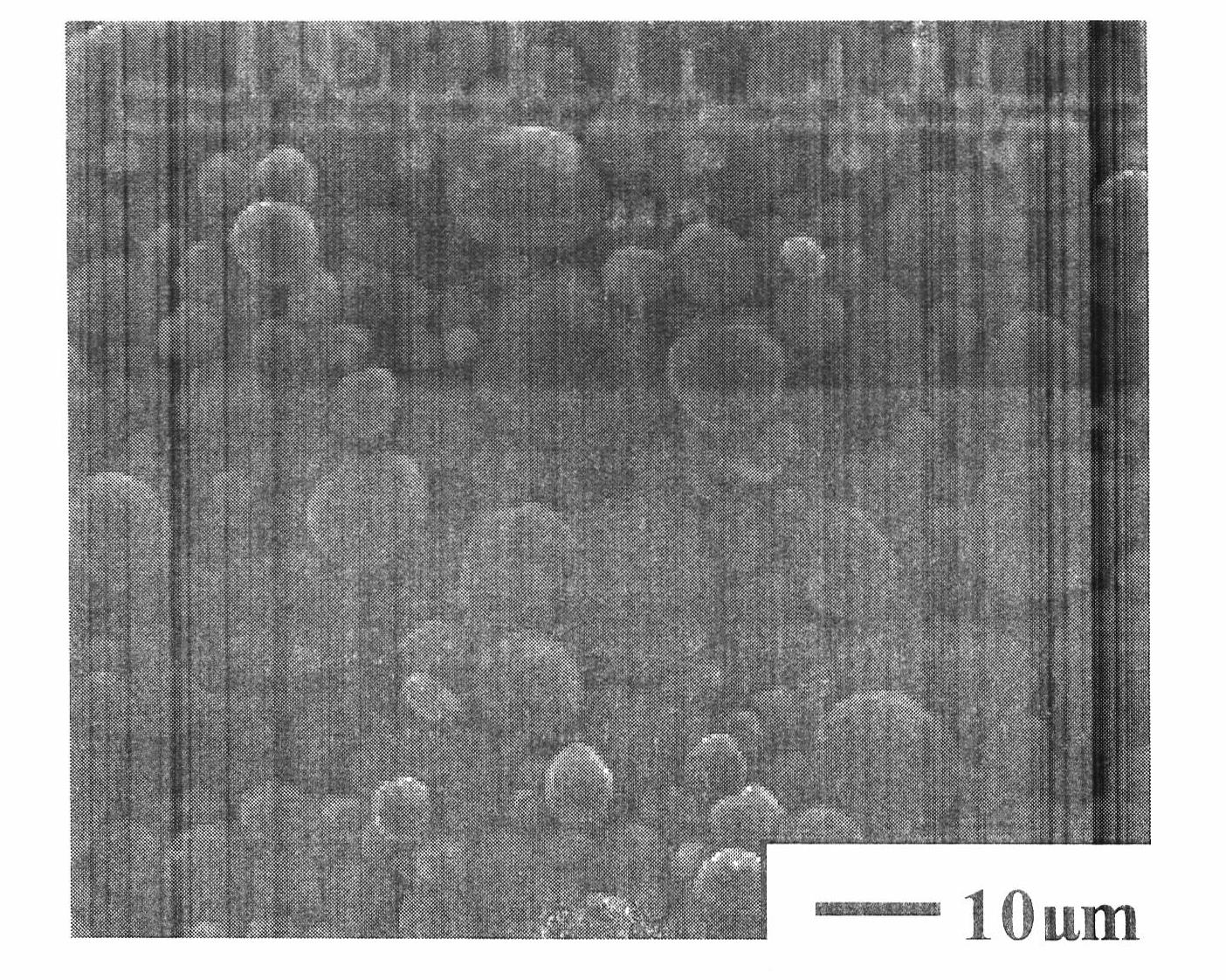

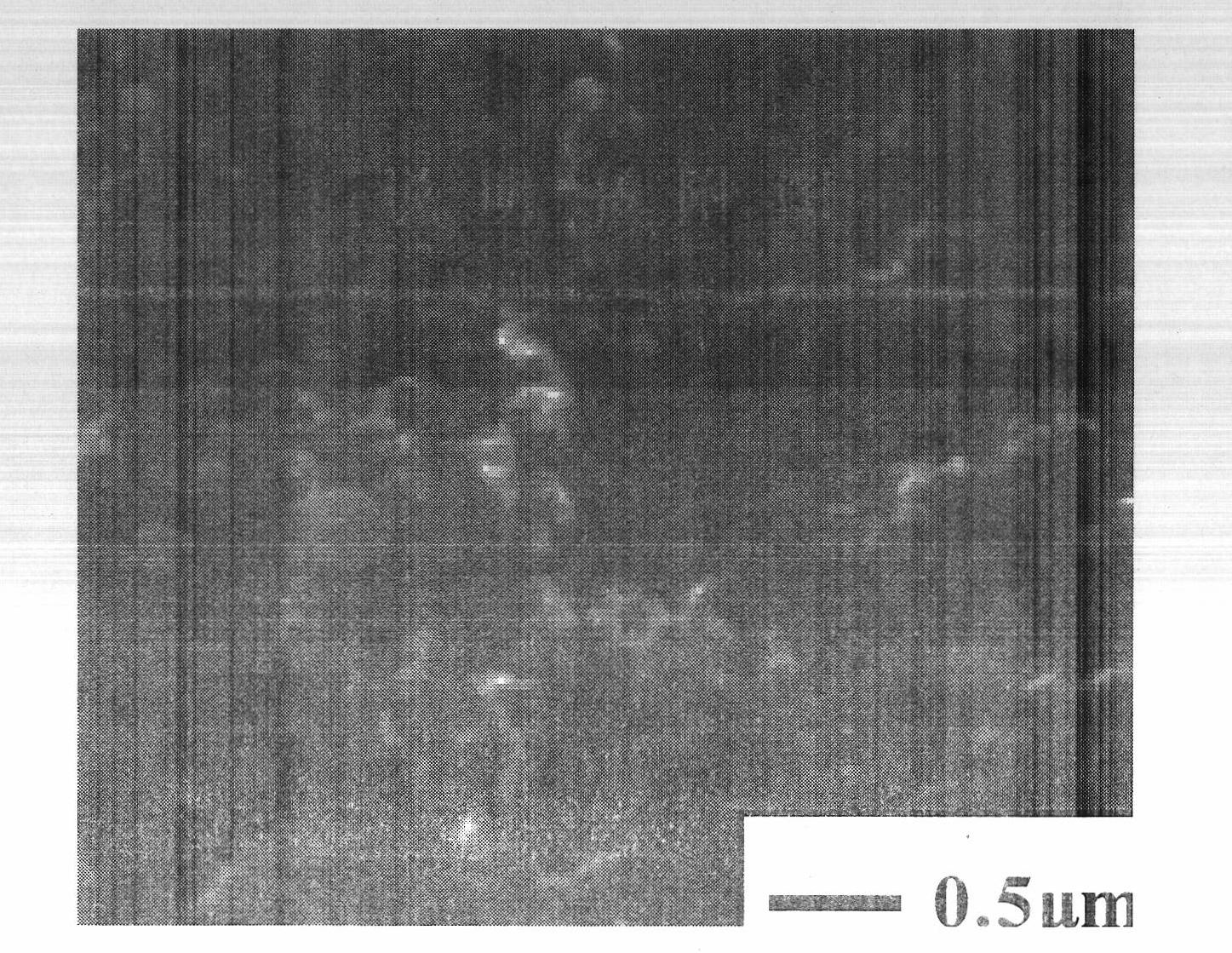

Embodiment 1

[0037] Take α=0, β=0.19, γ=0.15, δ=z=0, and M I for Ni, M II For Co and Al, the molecular formula Li[Li 0.14 Ni 0.19 mn 0.52 co 0.10 Al 0.05 ]O 2 . Prepare NiSO according to the molar ratio of Ni, Co, Mn and Al in the molecular formula 4 , MnSO 4 、CoSO 4 、Al 2 (SO 4 ) 3 The mixed deionized aqueous solution, the cation concentration is controlled at 2.0mol / L. Under the stirring condition of the peristaltic pump, the above mixed solution was added dropwise into another mixed aqueous solution composed of ammonia water and NaOH, the pH was controlled between 10 and 12, and the temperature of the water bath was kept at 60°C. After the reaction is completed, filter, wash, and vacuum-dry at 120° C. for 12 hours to obtain the reaction precursor MOH (M=Ni, Co, Mn, Al). The precursor is proportionally mixed with LiOH·H 2 O was ball milled and mixed in acetone for 1 hour, and then dried at a constant temperature of 60°C. The obtained precursor was first kept at 450°C for 6...

Embodiment 2

[0041] Take α=0.02, β=0.19, γ=0.15, δ=z=0, A is Ag, M I for Ni, M II For Co and Al, the formula Li is obtained 0.98 Ag 0.02 [Li 0.14 Ni 0.19 mn 0.52 co 0.10 Al 0.05 ]O 2 . According to the method in Example 1, the reaction precursor MOH (M=Ni, Co, Mn, Al) was prepared according to the ratio of Ni, Mn, Co, Al in the above molecular formula. The above precursors were proportionally mixed with LiOH·H 2 O and Ag 2 O was ball-milled and mixed in acetone for 1 hour, and then dried at a constant temperature of 60°C. The resulting precursor was kept at a constant temperature of 450°C for 6 hours in an air atmosphere, then heated to 900°C for 12 hours, and cooled to room temperature with the furnace to obtain sample 2:

[0042] Li 0.98 Ag 0.02 [Li 0.14 Ni 0.19 mn 0.52 co 0.10 Al 0.05 ]O 2 . Experiments have found that Ag can partially replace Ni, Co or Al, and the substitution amount is about 6-9 atom% of Ag.

Embodiment 3

[0044] Take α=0.02, β=0.19, γ=0.15, δ=z=0.05, A is Ag, M I for Ni, M II for Co and Al, X for F,

[0045] The molecular formula is obtained as Li 0.98 Ag 0.02 [Li 0.14 Ni 0.19 mn 0.52 co 0.10 Al 0.05 ]O 1.95 f 0.05 of active substances. According to the method in Example 1, the reaction precursor MOH (M=Ni, Co, Mn, Al) was prepared according to the ratio of Ni, Mn, Co, Al in the above molecular formula. The above precursors were proportionally mixed with LiOH·H 2 O, Ag 2 O and LiF were mixed in acetone for 1 hour and dried at a constant temperature of 60°C. The obtained precursor was first kept at 450°C for 6 hours in an air atmosphere, then heated to 900°C for 12 hours, and cooled to room temperature with the furnace to obtain sample 3:

[0046] Li 0.98 Ag 0.02 [Li 0.14 Ni 0.19 mn 0.52 co 0.10 Al 0.05 ]O 1.95 f 0.05 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com