Modified graphite and its preparing method

A graphite and modification technology, applied in the field of modified graphite and its preparation, can solve the problems of high cost, difficult industrial production, and difficult process, and achieve the effects of low cost, long cycle life and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

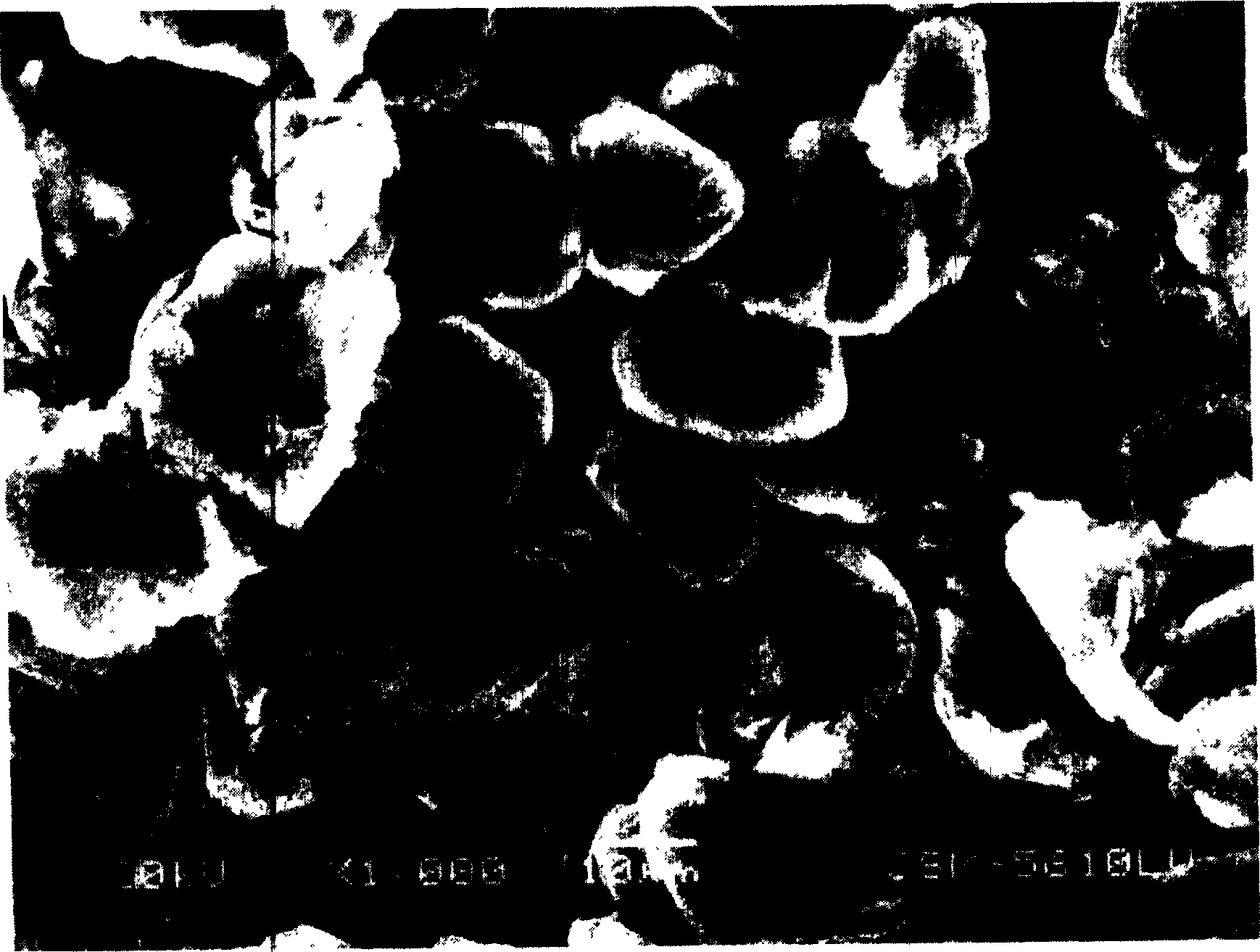

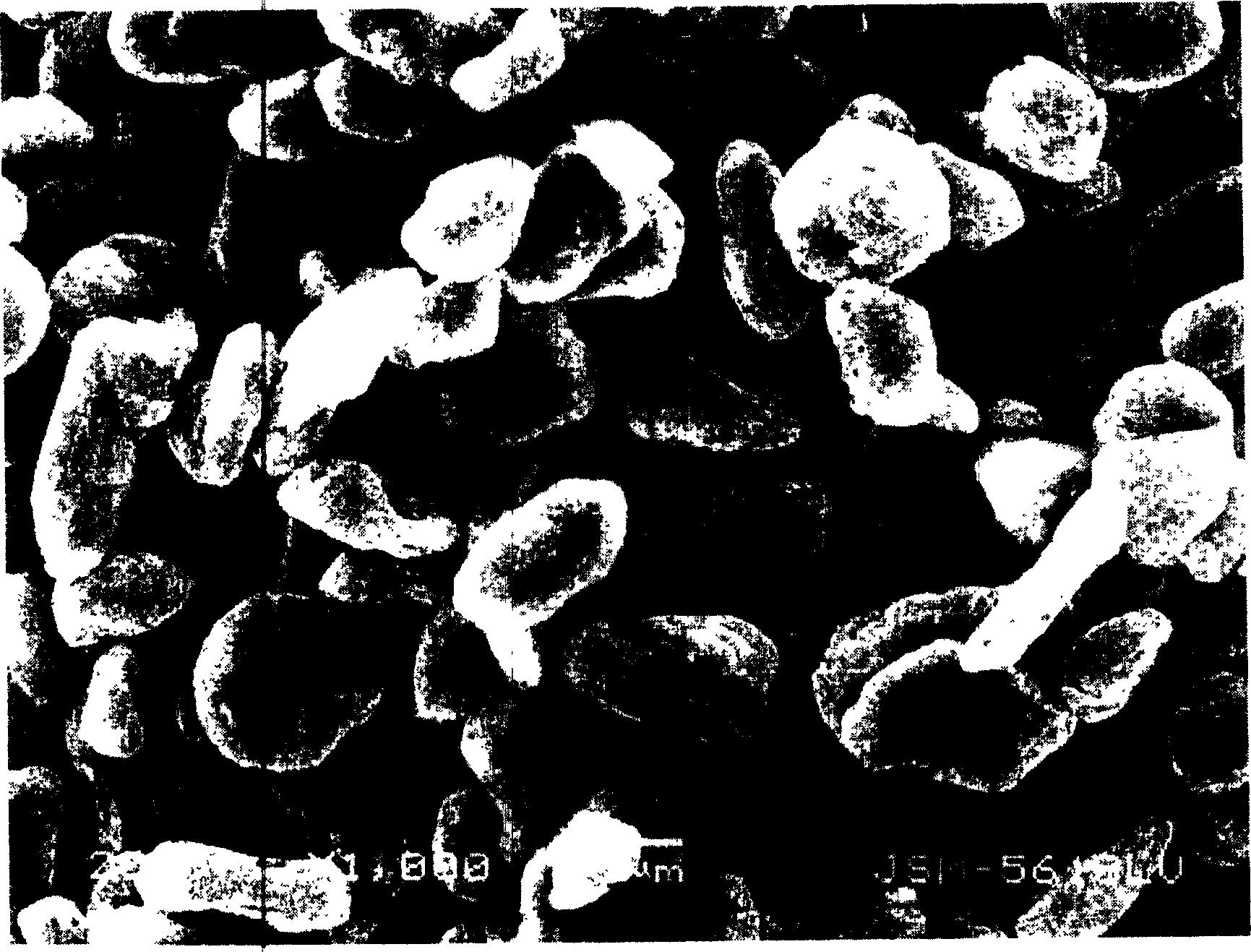

[0047]In the present invention, the modified graphite is mainly obtained by surface modification treatment of natural graphite or artificial graphite with a relatively high degree of graphitization. The preparation method includes the following steps: pre-preparing an organic solution of a polymer surface modifier with a certain concentration (generally saturated or close to saturation); immersing the graphite core material in it and stirring it, the stirring speed is 100-2000rpm, and the stirring time 0.5~10h; then separate (filter or centrifuge) the graphite in it, dry the solvent involved in it, and sieve; finally, the dry graphite obtained is solidified and carbonized under a protective atmosphere without crushing process The modified graphite of the present invention can be obtained.

[0048] In the preparation method of modified graphite of the present invention, described surface modifier is a kind of very high organic matter of carbon content, can be coal pitch, coal t...

Embodiment 1

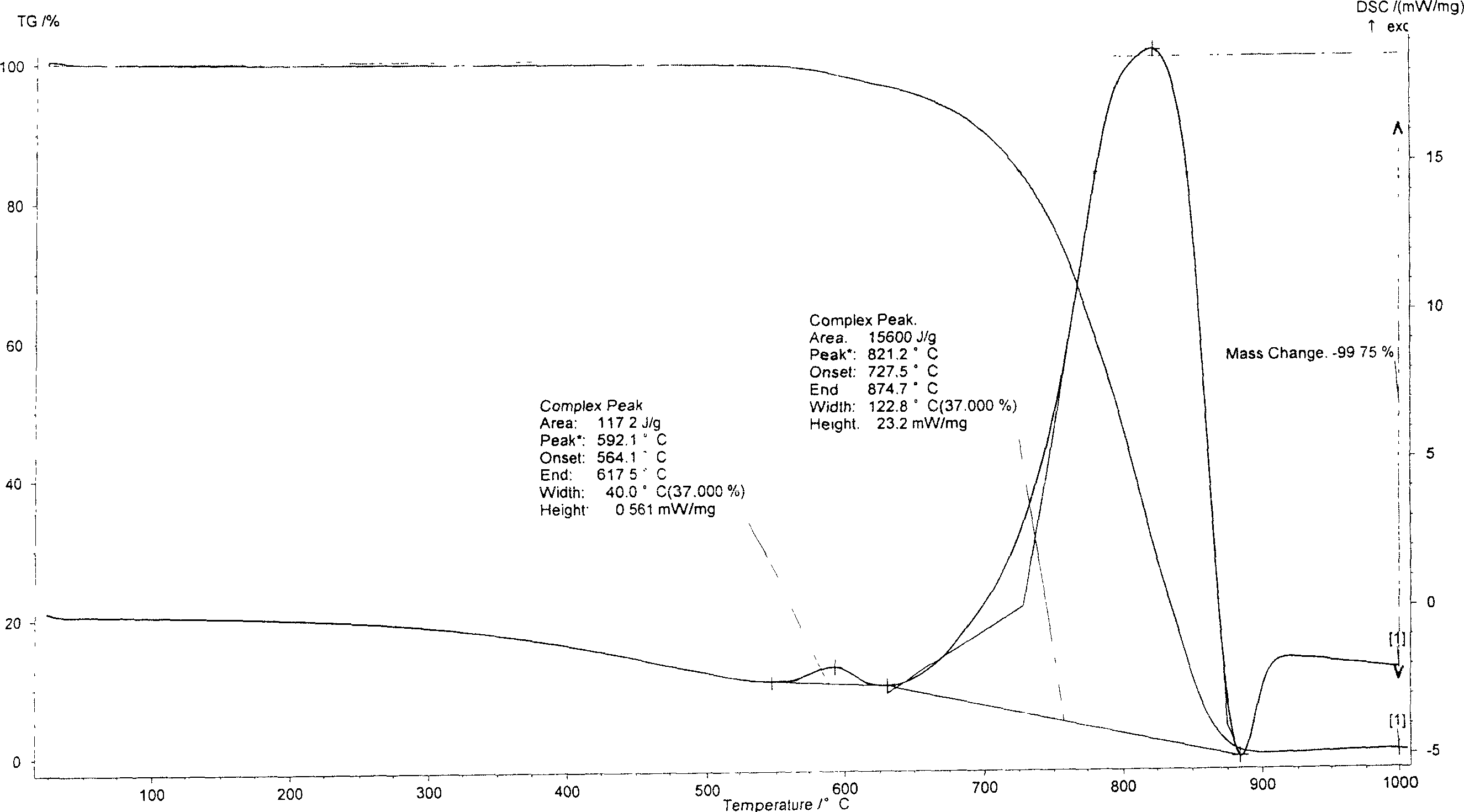

[0055] Weigh 8 g of petroleum tar, dissolve it in carbon tetrachloride, and prepare 200 ml of a 4% surface modifier solution for later use. Weigh 100g of dry natural graphite, dip it in the organic solution of the surface modifier, and stir it at a speed of 300rpm for 1 hour, so that a thin layer of surface modification film is formed on the surface of the graphite particles. Then filter to obtain graphite, dry, and pass through a 300-mesh sieve. Put the sieved graphite into a closed tubular high-temperature furnace, and pass high-purity N at a flow rate of 10 liters / min. 2 , the heating rate was raised to 400°C at a rate of 15°C / min, kept for 1 hour, and then raised to 1000°C at a rate of 10°C / min, kept at a temperature of 3 hours, and naturally cooled to room temperature to obtain surface-modified graphite. The graphite is D 50 The average particle size of the characterization is 13.8μm, and the distance between the crystallite layers is d 002 is 0.3365, and the specific ...

Embodiment 2

[0058] In this example, the surface modification agent is 5% coal tar pitch in tetrahydrofuran solution, except that, other processes are consistent with Example 1. The average particle diameter D of the modified graphite that present embodiment obtains 50 and crystallite interlayer spacing d 002 Basically consistent with Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| face spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com