Silicon/graphite composite anode material and preparation method thereof

A negative electrode material and graphite technology, which is applied in the field of silicon/graphite composite negative electrode material and its preparation, can solve the problems of unstable SEI film and low coulombic efficiency of negative electrode materials, so as to avoid thickness growth, improve coulombic efficiency and cycle stability, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

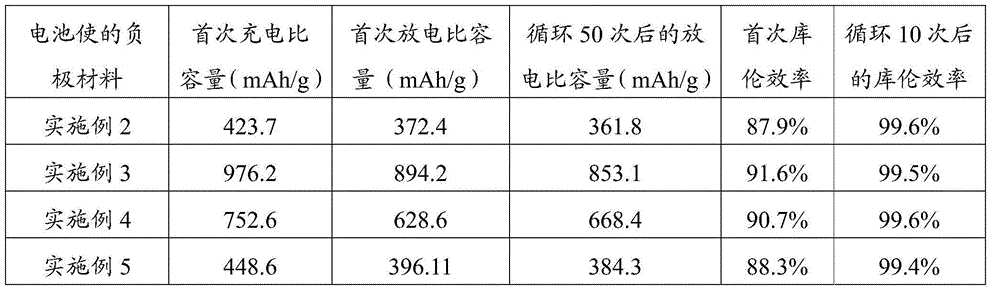

Examples

preparation example Construction

[0030] On the one hand, an embodiment of the present invention provides a method for preparing a silicon / graphite composite negative electrode material, the method comprising the following steps:

[0031] Step 101, putting the mixture of elemental silicon particles and graphite in a ball mill for ball milling to obtain a ball milled product.

[0032] In the embodiment of the present invention, graphite with a small specific surface area is selected as a material for buffering the volume effect of silicon. Through ball milling, the silicon particles are nano-dispersed in the graphite sheet structure and are in contact with the graphite sheet structure. Therefore, the lamellar structure of graphite and the gaps between nano-dispersed silicon particles can provide a large number of channels for lithium ions, increase the insertion position of lithium ions, so as to achieve the purpose of buffering the volume effect of silicon materials and effectively improve the preparation. Cy...

Embodiment 1

[0059] This embodiment provides a silicon / graphite composite negative electrode material, the preparation steps of which are as follows:

[0060] Mix 1.0 g of silicon powder (150 nm in particle size) and 4.0 g of artificial graphite (10 μm in particle size), put them into a planetary ball mill, and ball mill at 300 rpm for 4 hours to obtain a ball milled product. The ball-milled product was put into a mixed solution consisting of 10ml of ammonia (25% mass fraction), 10ml of hydrogen peroxide (30% mass fraction) and 50ml of water, heated to boiling, and stirred for 30min in a boiling state. Then the ball-milled product was taken out, washed with water, filtered and vacuum-dried at 80° C. for 12 hours to obtain a dry product. Add 4.0 g of the dried product to an absolute ethanol solution containing 0.06 g of a silane coupling agent (γ-glycidyl etheroxypropyltrimethylsilane) (wherein the mass of absolute ethanol is 20 g), at 50° C. Heat and stir for 30min. Then, slowly add 5 g ...

Embodiment 2

[0065] This embodiment provides a silicon / graphite composite negative electrode material, the preparation steps of which are as follows:

[0066] Mix 1.0 g of silicon powder (with a particle size of 5 μm) and 10.0 g of natural graphite (with a particle size of 25 μm), put them into a planetary ball mill, and ball mill at 400 rpm for 16 hours to obtain a ball milled product. 10g of this ball mill product was put into a mixed solution consisting of 20ml of ammonia (25% mass fraction), 20ml of hydrogen peroxide (30% mass fraction) and 100ml of water, heated to boiling, and stirred for 60min in a boiling state. Then the ball-milled product was taken out, washed with water, filtered and vacuum-dried at 120° C. for 2 hours to obtain a dried product. Add 8.0 g of this dry product to an absolute ethanol solution containing 0.008 g of a silane coupling agent (3-(N,N-dimethylaminopropyl)-aminopropylmethyldimethoxysilane) (wherein, The mass of absolute ethanol is 40 g), heated and stirr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com