Artificial graphite composite negative electrode material for lithium ion battery and preparation method for negative electrode material

A lithium-ion battery, artificial graphite technology, applied in battery electrodes, electrode manufacturing, electrode heat treatment and other directions, can solve the problems of complex preparation process, high price of mesocarbon microspheres, etc., achieve simple process, not easy to loosen and disintegrate, small The effect of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

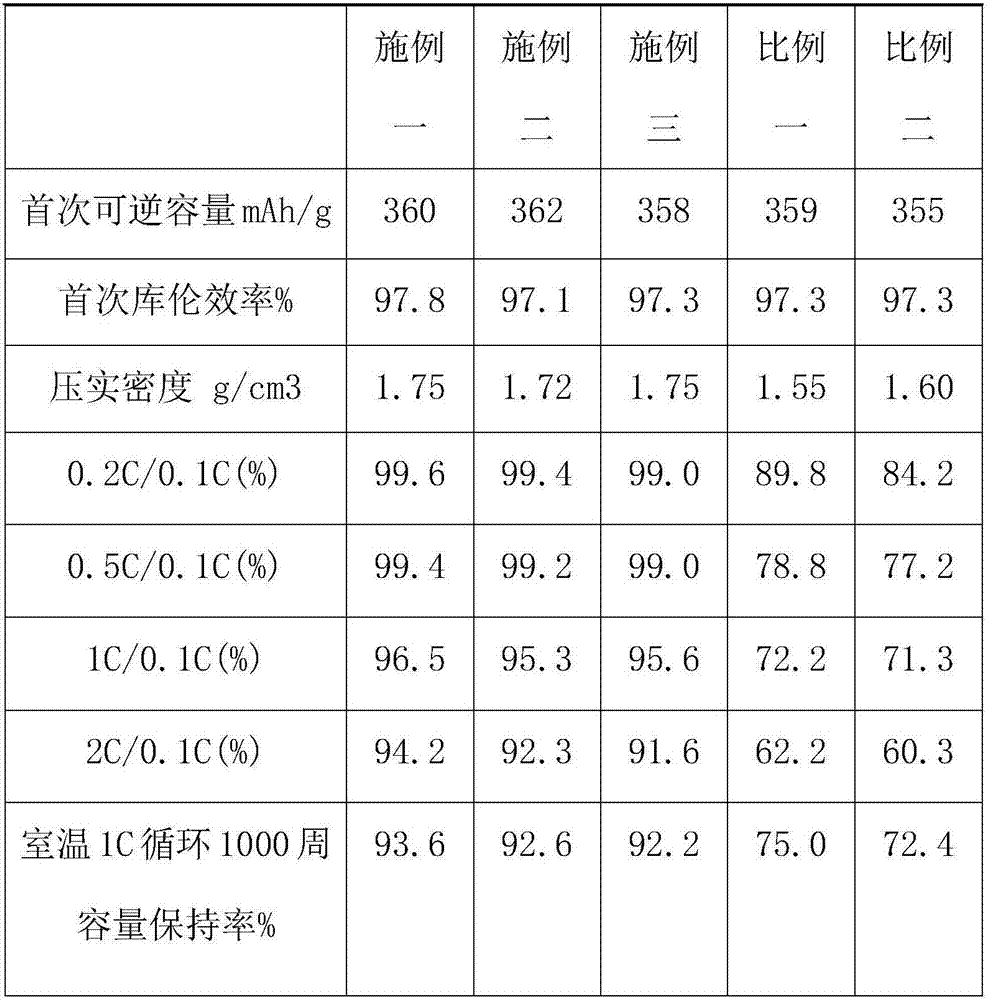

Embodiment 1

[0024] A kind of preparation method of artificial graphite composite negative electrode material for lithium ion battery proposed by the present invention comprises the following steps:

[0025] a. Crushing and grading petroleum-based needle coke in an impact mill to obtain powders with an average particle size D50 of 14-18 μm and an average particle size D50 of 3-6 μm;

[0026] b. Uniformly mix the powders with the average particle size D50 obtained in step a of 14-18 μm and the average particle size D50 of 3-6 μm according to a mass ratio of 100:10 to obtain a composite precursor;

[0027] c. Spheroidizing the composite precursor obtained in step b;

[0028] d. Graphitizing the material obtained in step c for 6 hours at a high temperature of 2600° C.;

[0029] E, the material that step d obtains is uniformly mixed with asphalt according to mass ratio 100:2;

[0030] f, put the material obtained in step e in N 2 Under protection, treat at 1200°C for 4 hours, cool to room t...

Embodiment 2

[0032] A kind of preparation method of artificial graphite composite negative electrode material for lithium ion battery proposed by the present invention comprises the following steps:

[0033] a. The calcined coke of the coal-based needle coke is pulverized and classified in an impact mill to obtain powders with an average particle size D50 of 16-20 μm and an average particle size D50 of 3-5 μm;

[0034] b. Uniformly mix powders of two particle sizes obtained in step a with an average particle size D50 of 16-20 μm and an average particle size D50 of 3-5 μm according to a mass ratio of 100:5 to obtain a composite precursor;

[0035] c. Spheroidizing the composite precursor obtained in step b;

[0036] d. Graphitizing the material obtained in step c for 10 h at a high temperature of 2800° C.;

[0037] E, the material obtained in step d is uniformly mixed with epoxy resin according to the mass ratio of 100:1;

[0038] f, put the material obtained in step e in N 2 Under prote...

Embodiment 3

[0040] A kind of preparation method of artificial graphite composite negative electrode material for lithium ion battery proposed by the present invention comprises the following steps:

[0041] a. Carry out pulverization and classification of petroleum-based calcined coke in an impact mill to obtain powders with an average particle diameter D50 of 18-22 μm and an average particle diameter D50 of 5-8 μm;

[0042] b. The average particle size D50 obtained in step a is 18-22 μm and the average particle size D50 is 5-8 μm, and the powders with two particle sizes are uniformly mixed according to the mass ratio of 100:8 to obtain a composite precursor;

[0043] c. Spheroidizing the composite precursor obtained in step b;

[0044] d. Graphitizing the material obtained in step c for 10 h at a high temperature of 2800° C.;

[0045] E, the material obtained in step d is uniformly mixed with glucose according to the mass ratio of 100:5;

[0046] f, put the material obtained in step e ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com