Carbon cladding layer expansion graphite composite material used for lithium ion batteries and preparation method thereof

A technology for lithium ion batteries and composite materials, applied in the field of graphite-based composite materials and preparation, can solve the problems of unfavorable industrial application of modified expanded graphite negative electrode materials for lithium ion batteries, unfavorable electrochemical stability of materials, and serious damage of nearly spherical graphite. and other problems, to achieve the effect of improving high power performance, increasing reversible specific capacity, and improving electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The carbon-coated expanded graphite composite negative electrode material for lithium ion batteries has a "shell-core" structure, the inner core is expanded graphite doped with phosphorus, the outer shell is the pyrolysis product of phenolic resin, and the graphite layer spacing is 0.3387nm.

[0024] The preparation method of the above-mentioned carbon-coated expanded graphite composite negative electrode material is as follows:

[0025] Step 1: In N 2 Under the protection of the atmosphere, the microcrystalline graphite raw material was heated to 1000° C., heat-treated at a constant temperature for 0.5 h, and the pretreated microcrystalline graphite raw material was obtained after cooling.

[0026] The second step: at the temperature of -10 ° C, 10 g of the pretreated microcrystalline graphite raw material, 10 g of NaNO 3 and 20g of oxalic acid were added to 20.0ml of 85% concentrated H 3 PO 4 solution, after stirring evenly, let stand for 12h, graphite: H 3 PO 4 ...

Embodiment 2

[0029] The carbon-coated expanded graphite composite negative electrode material for lithium ion batteries has a "shell-core" structure, the inner core is expanded graphite doped with phosphorus, the outer shell is the pyrolysis product of phenolic resin, and the graphite layer spacing is 0.3383nm.

[0030] The preparation method of the above-mentioned carbon-coated expanded graphite composite negative electrode material is as follows:

[0031] Step 1: In N 2 Under the protection of the atmosphere, the microcrystalline is heated to 1000°C, heat-treated at a constant temperature for 2 hours, and the pretreated microcrystalline graphite raw material is obtained after cooling.

[0032] The second step: at a temperature of 20 ° C, 10 g of pretreated microcrystalline graphite raw materials, 15 g of NaNO 3 and 50g of acetic acid were sequentially added to 80.0ml of NH with a concentration of 300g / l 4 h 2 PO 4 solution, after stirring evenly, let stand for 10h, graphite: NH 4 h 2...

Embodiment 3

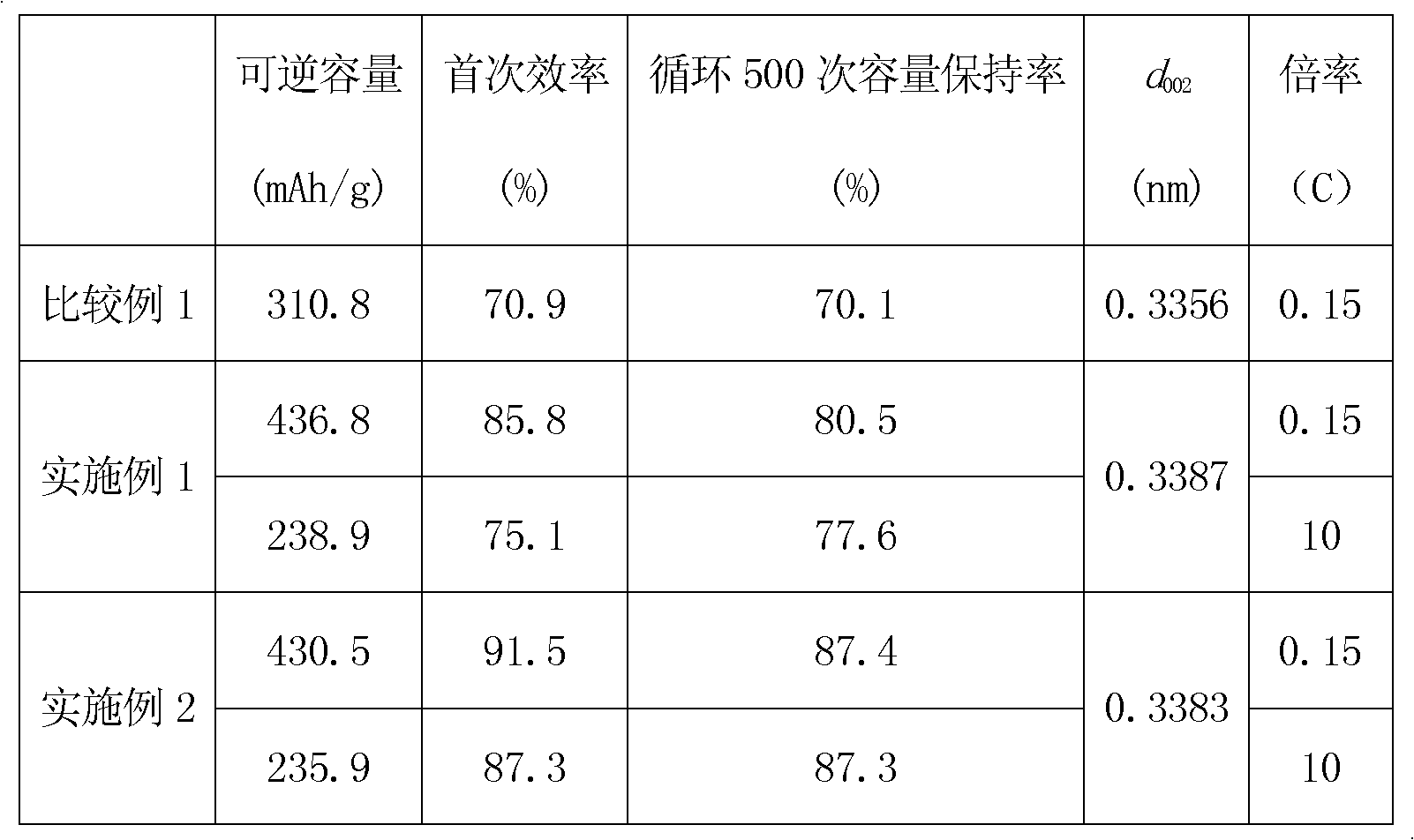

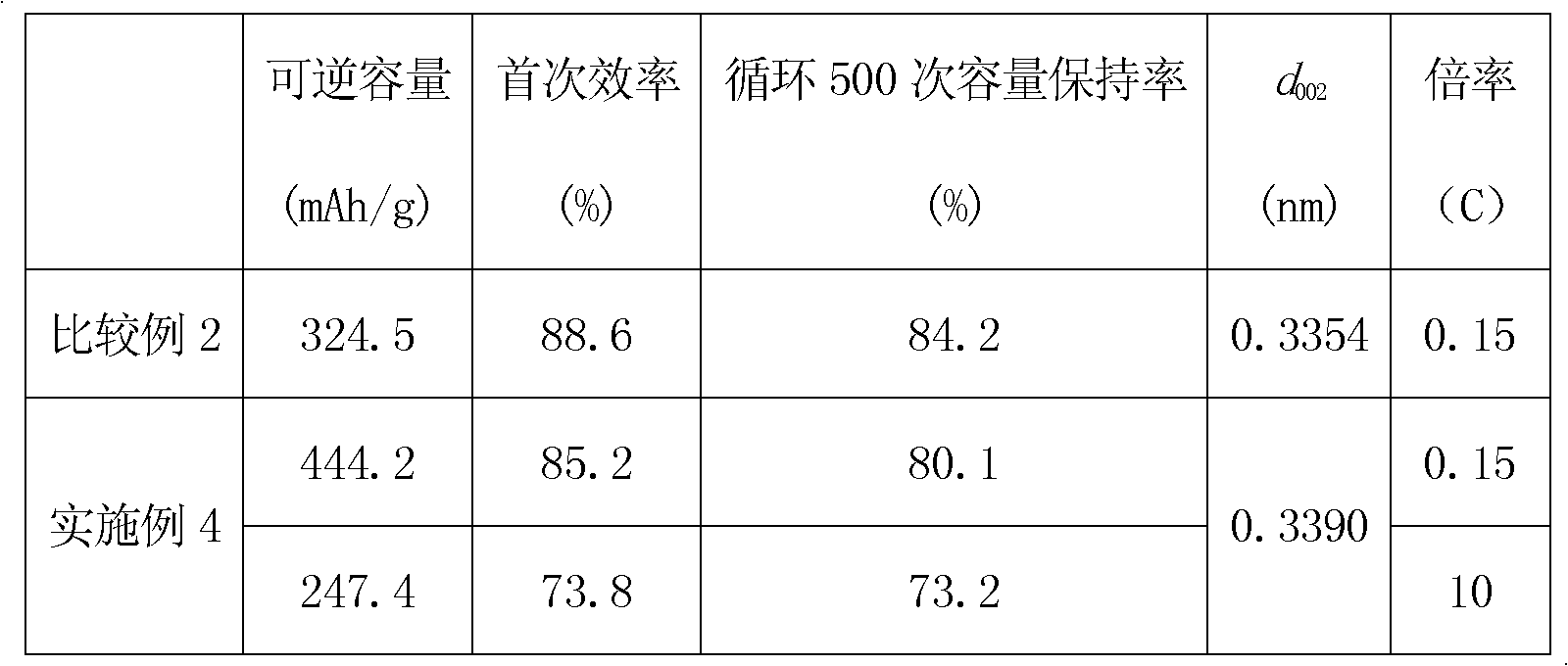

[0035] The above-mentioned carbon-coated expanded graphite composite negative electrode material fine powder was made into an electrode; as a comparison, the microcrystalline graphite was ground, and then passed through a 325-mesh sieve, and the resulting -325-mesh graphite powder was made into an electrode. This is Comparative Example 1. Other test conditions are the same, the test results are as follows:

[0036]

[0037] The comparison results show that the interlayer spacing of the carbon-coated expanded graphite composite negative electrode material of the present invention is slightly larger than that of the microcrystalline graphite material, and the reversible specific capacity and cycle life of the lithium ion battery negative electrode made with it under the charging and discharging conditions of 0.15C and 10C The electrochemical performance has been greatly improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Layer spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com