Abrasive article and method for making the same

a technology of abrasive articles and abrasive particles, which is applied in the direction of abrasive equipment, pigmentation treatment, other chemical processes, etc., can solve the problems of hammering the performance and usable life of abrasive tools, limited cutting ability, and poor abrasive particle retention, so as to reduce the overall amount of abrasive particles needed, reduce the cost of making tools, and increase the service life of expensive abrasive particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

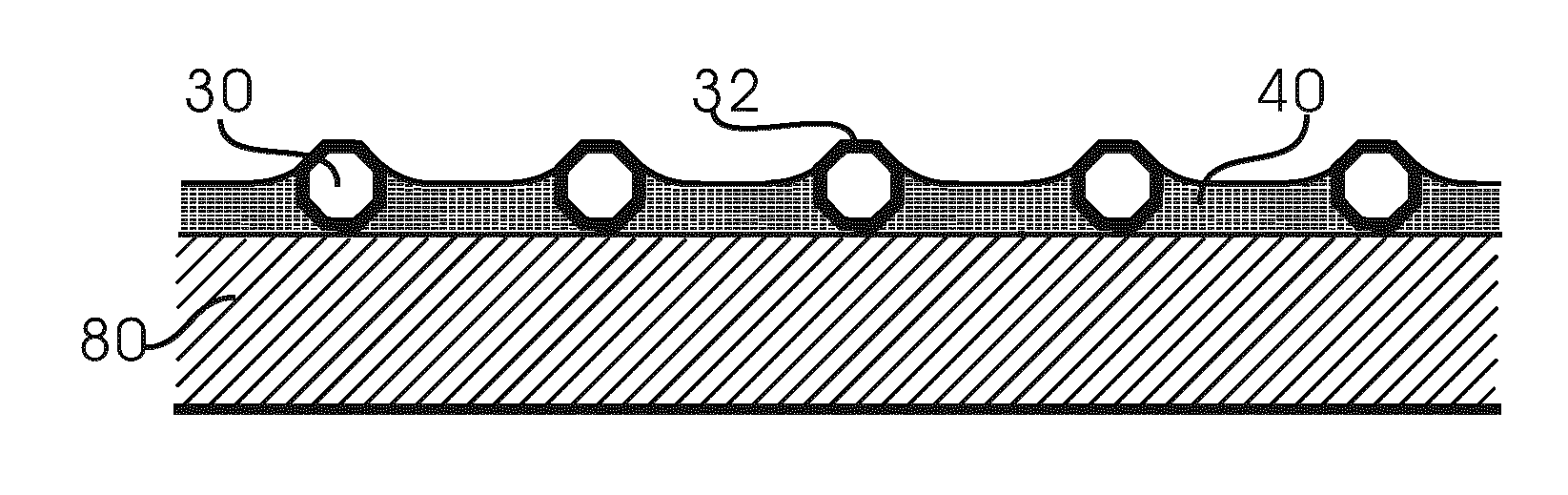

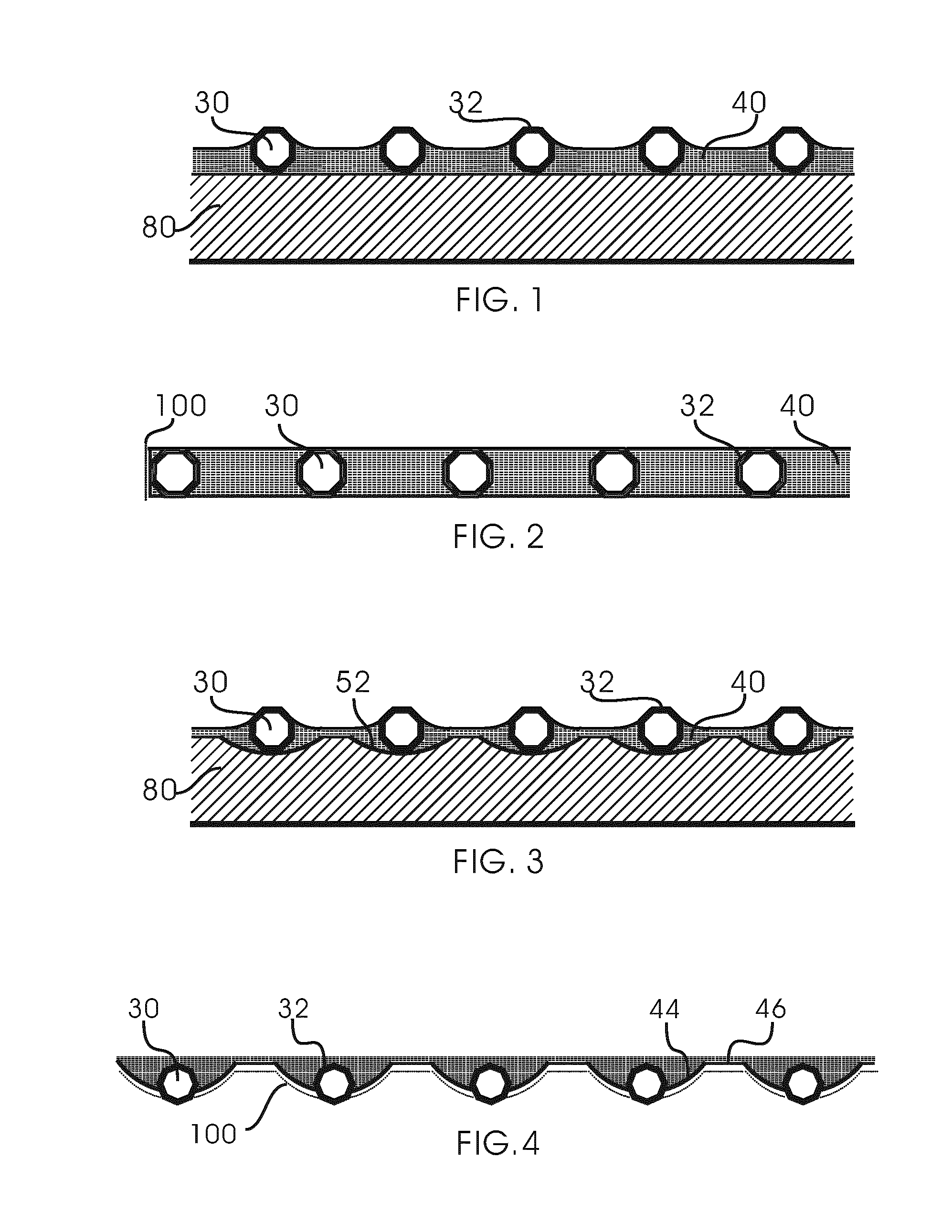

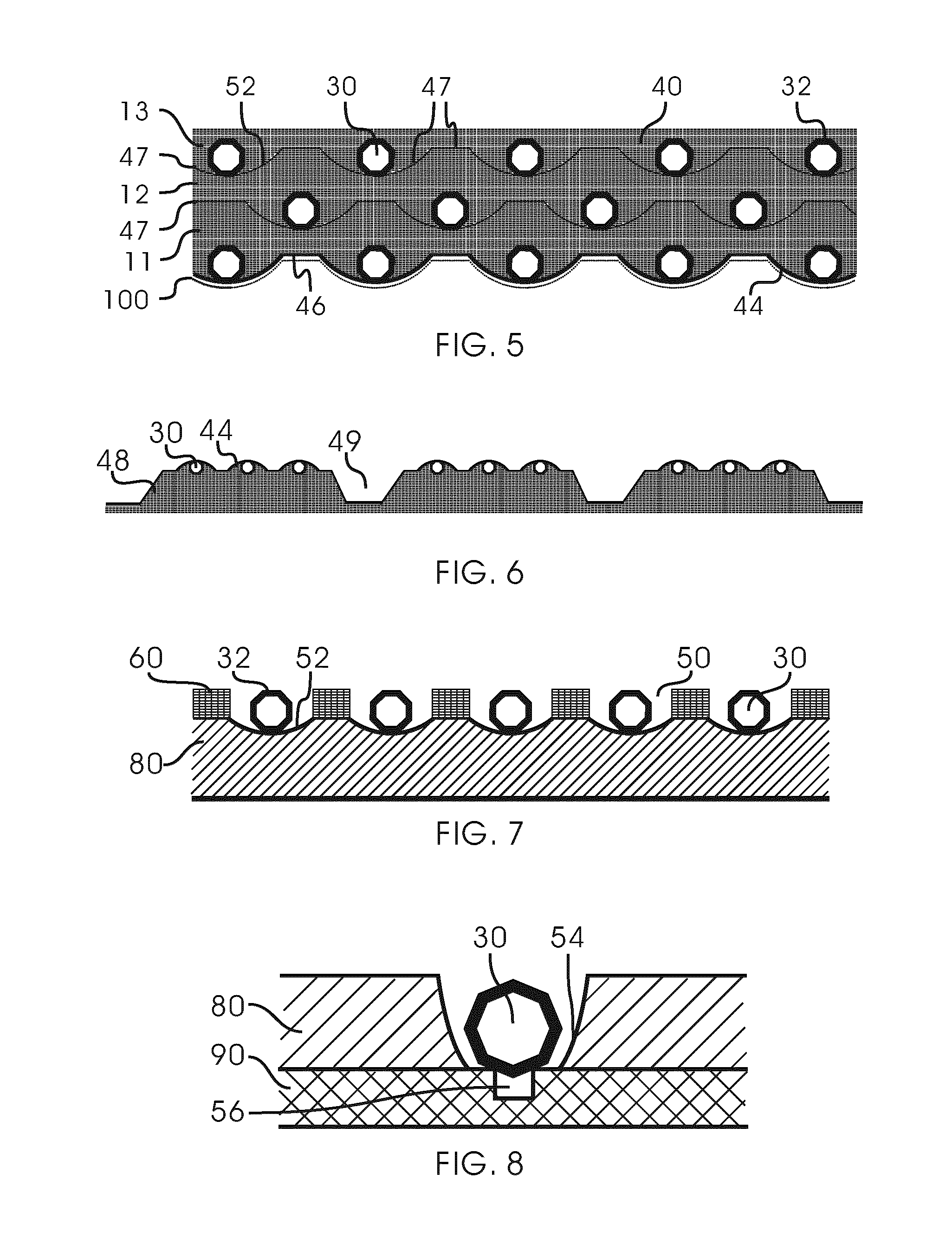

Image

Examples

example 1

[0109]A stainless steel disc (120D-0.65T) that is about 120 mm in diameter and about 0.65 mm in thickness is partially covered by an electrically non-conductive template having a plurality of apertures distributed in a lattice pattern. The template covers a generally circular area on a central portion of the disc of about 100 mm in diameter, leaving a width of about 10 mm around the perimeter of the disc. The perimeter area is covered by an insulating material to prevent deposition. The aperture separation measuring from the approximate center points of adjacent apertures is about 800 microns with each aperture about 400 microns in diameter. Nickel coated diamond particles with an average size of 300 microns are then dispersed into the apertures so that each aperture accommodates only a single grain. The excess diamond grains are discarded by brushing, titling, vibrating, shaking, etc. The located diamond grains are bonded to the steel substrate by an electroplating process. A 99.99...

example 2

[0110]The process of Example 1 is followed, except the diamond grains used in the present example are naked (with no metallic coating) and magnetically sensitive as a result of containing inclusions of catalysts such as nickel, cobalt, iron, manganese, or like. These grains are normally excluded in fabrication of electroplated diamond tools because they lead to the formation of nodules around diamond grains, over-plating of the grains, and pores in plated material between grains. Individual placement of the grains in the present invention successfully prevents the formation of such pores which are detrimental to the abrasive retention.

example 3

[0111]A substrate metal having a shape and a dimension of 240D-20T is prepared from stainless steel (SUS304) by working using a lathe. Then, the substrate surface is covered by an electrically non-conductive template, and the other part is masked with an insulation tape. The template has apertures in grid pattern with aperture diameter of 200 microns and aperture separation of 400 microns. The substrate is then treated for degreasing with an alkali and dipped into a pretreatment fluid containing 240 g / liter of nickel chloride and 100 g / liter of hydrochloric acid. The dipped substrate is set to an anode and electrolytically etched under a current density of 10 A / dm.sup.2 at an ordinary temperature for 2 minutes. Then, the substrate is set to a cathode, and strike plating is conducted for 3 minutes. The treated substrate is plated in a plating bath of nickel sulfamate under a current density of 1 A / dm.sup.2 for 15 minutes to form a thin plating underlayer. The purpose of the early pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Force | aaaaa | aaaaa |

| Structure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com