Method for preparing composite graphene/silane film on surface of metal

A technology of metal surface and composite thin film, which is applied in the direction of metal material coating process, liquid chemical plating, coating, etc., can solve the problems of weak bonding strength, achieve high bonding strength, and improve the effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0033] 1 Preparation of graphene oxide dispersion

[0034] 1) Pre-oxidation

[0035] Take 3g artificial graphite and 10ml concentrated H 2 SO 4 , 1gP 2 o 5 , 1gK 2 S 2 o 8 The mixture was placed in a three-necked flask, heated to 80°C and maintained for 2h, until the solution in the three-necked flask was blue-black, then stop heating, and the reactant was naturally cooled to room temperature, and allowed to stand for 6h; the reactant was filtered, and continuously rinsed with distilled water, The reactant was filtered until the filtrate was neutral, and finally the obtained solid was air-dried at room temperature for 24 h.

[0036] 2) Oxidation and dispersion by Hummers method

[0037] Take 1gNaNO 3 Place in a three-necked flask, add 50ml of concentrated H 2 SO 4 , and keep stirring to make NaNO 3 Fully dissolved in concentrated H 2 SO 4 In the above solution, take the dried pre-oxidized product and add it to the above solution, place the three-necked fl...

Embodiment example 2

[0043] 1 Preparation of graphene oxide dispersion

[0044] The preparation method of graphene oxide is the same as that of case 1. Dissolve 0.001g of graphene oxide in 1ml of N-methylpyrrolidone (density of 1.028 g / mL at 25°C) solution (the mass concentration of graphene oxide is 0.097%), and after ultrasonication for 2 hours A uniform dispersion is formed and sealed for storage until use.

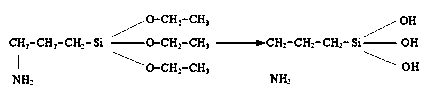

[0045] 2 Preparation of γ-aminopropyltrimethoxysilane grafted graphene oxide

[0046] Take 15ml of γ-aminopropyltrimethoxysilane (APTMS structure as Figure 6 Shown) Slowly drop into the dispersion under stirring, stir and react in a water bath at 80°C for 24h, through the NH of APTMS molecules 2 The group reacted with the COOH group on the surface of graphene oxide to complete grafting, and the obtained paste was ultrasonically dispersed for 2 hours to obtain a graphene oxide solution grafted with a silane coupling agent; the solution was placed in a water bath at 90°C, and slowly ...

Embodiment example 3

[0051] 1 Preparation of graphene oxide dispersion

[0052] The preparation method of graphene oxide is the same as that of case 1. Dissolve 0.001g of graphene oxide in 1ml of N-methylpyrrolidone (density of 1.100 g / mL at 20°C) solution (the mass concentration of graphene oxide is 0.091%), and after ultrasonication for 2 hours A uniform dispersion is formed and sealed for storage until use.

[0053] Preparation of 2γ-mercaptopropyltrimethoxysilane grafted graphene oxide

[0054] Take 20ml of γ-mercaptopropyltrimethoxysilane (MPTS structure as Figure 7 Shown) was slowly dropped into the dispersion liquid under stirring, stirred and reacted in a water bath at 90°C for 24 hours, the grafting was completed by the reaction of the SH group of the MPTS molecule with the COOH group on the surface of graphene oxide, and the obtained paste was ultrasonically dispersed After 2h, the graphene oxide solution grafted with silane coupling agent was obtained; the solution was placed in a wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com