Three-dimensional electrode bio-membrane system used for processing high-ammonium-nitrogen wastewater with low carbon-nitrogen ratio

A technology of biofilm system and three-dimensional electrode, which is applied in the direction of aerobic and anaerobic process treatment, to achieve the effect of product cleaning, increase of microbial biomass, improvement of current efficiency and treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

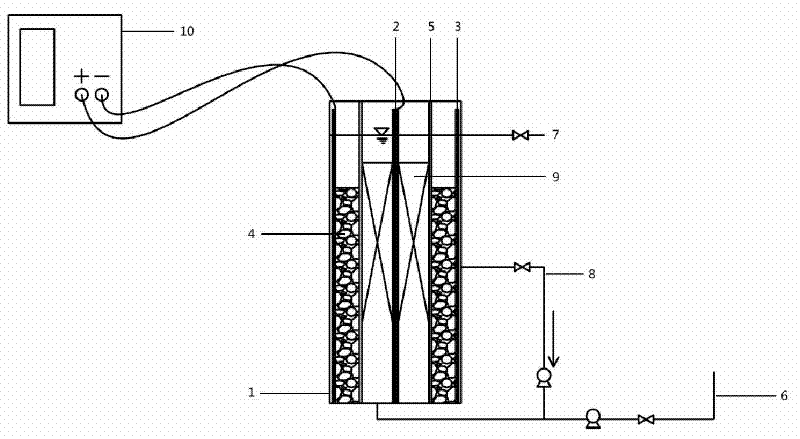

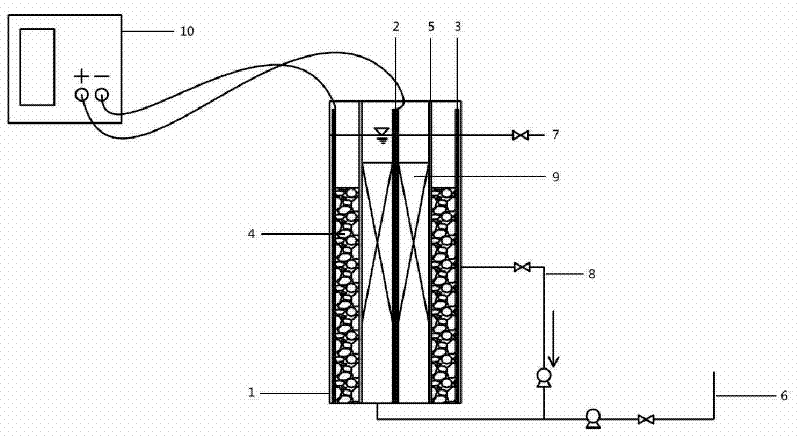

[0029] The three-dimensional electrode biofilm system of the present invention is mainly used to treat waste water with low carbon-to-nitrogen ratio and high ammonia-nitrogen, see figure 1 , the structural main body is a reactor body 1, the reactor body 1 adopts a cylindrical structure, and a diaphragm 5 concentric with the reactor body is arranged in the reactor body 1, and the inner region of the reactor is divided into an anode region and an anode region by the diaphragm. There are two parts of the cathode area, the circular area inside the diaphragm is the anode area, and the annular area between the outside of the diaphragm and the inner wall of the reactor body is the cathode area. The anode area is filled with microbial carrier filler 9, and a positive electrode 2 is provided in the center; a negative electrode 3 is provided i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com