Ejector for soil deep placement

A sprayer and soil technology, applied in the field of deep soil application sprayer, can solve the problems of destroying the plowing layer, demanding foundation conditions, soil damage, etc., and achieve the effect of small soil compaction, high power requirements, and high degree of integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

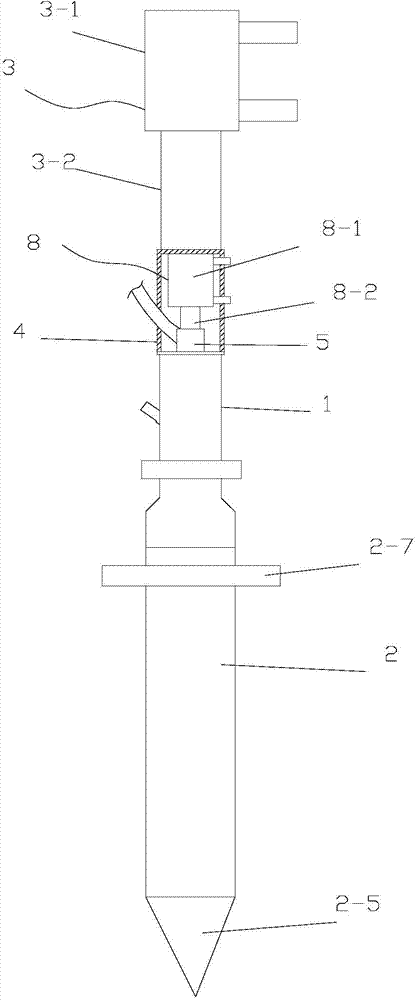

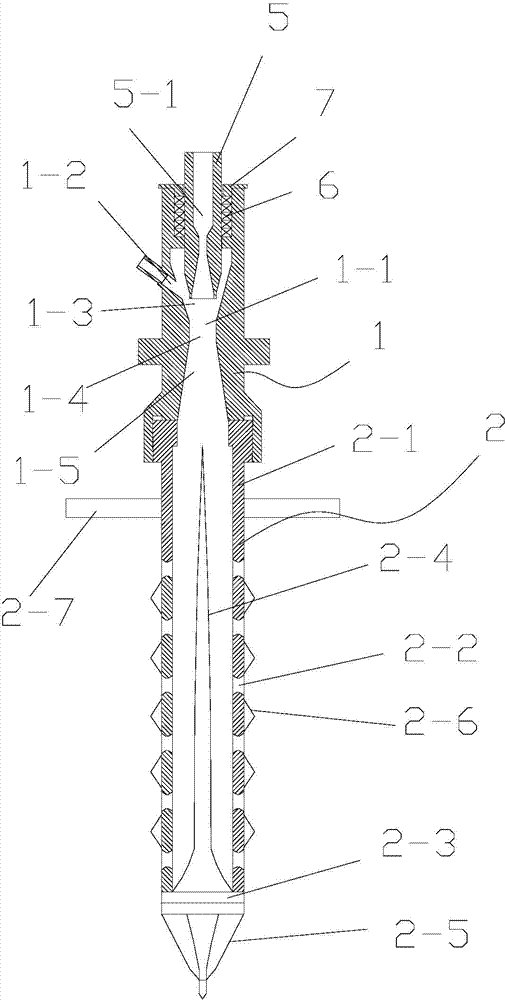

[0020] figure 1 It is a schematic diagram of the overall structure of the soil deep application injector of the present invention, figure 2 It is a longitudinal sectional view of the deep soil application injector of the present invention, as shown in the figure: the deep soil application injector of the present invention includes an air delivery device 1 for delivering high-pressure jet airflow, and the air flow delivery device 1 is provided with an air flow Channel 1-1 and fertilizer channel 1-2 for feeding fertilizer, the airflow channel 1-1 is a Venturi structure, and the fertilizer outlet of the fertilizer channel 1-2 communicates with the constriction area of the airflow channel 1-1 ; Because the airflow channel 1-1 is a Venturi structure, as shown in the figure, the airflow channel 1-1 of the Venturi structure includes a constriction zone 1-3, a weir zone 1-4 and an expansion zone 1-5, because the expansion zone pressure is higher At the bottom, the high-pressure je...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com