Preparation method of transparent silicon dioxide aerogel

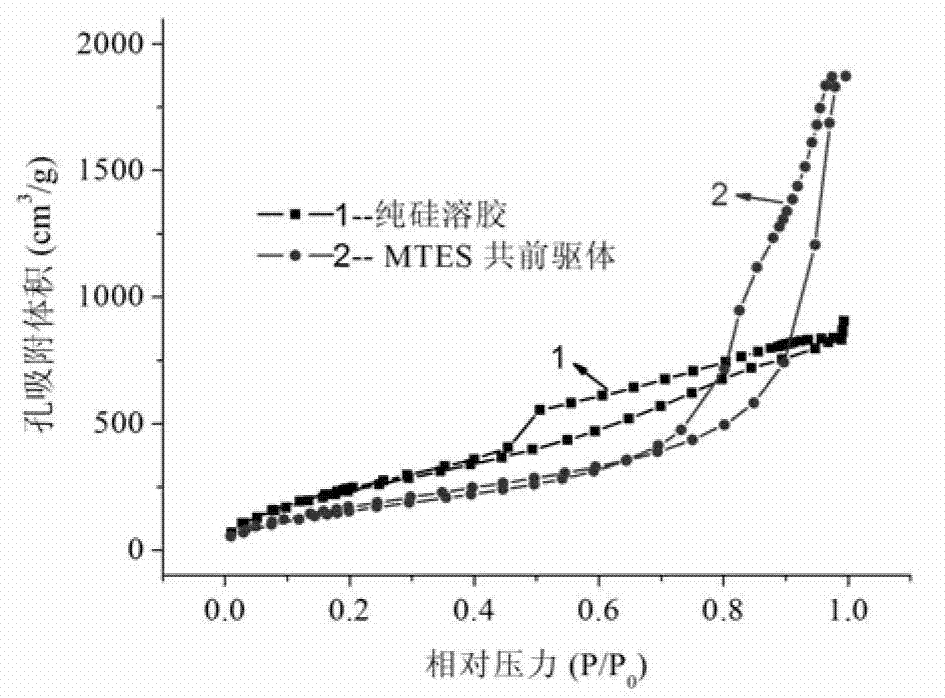

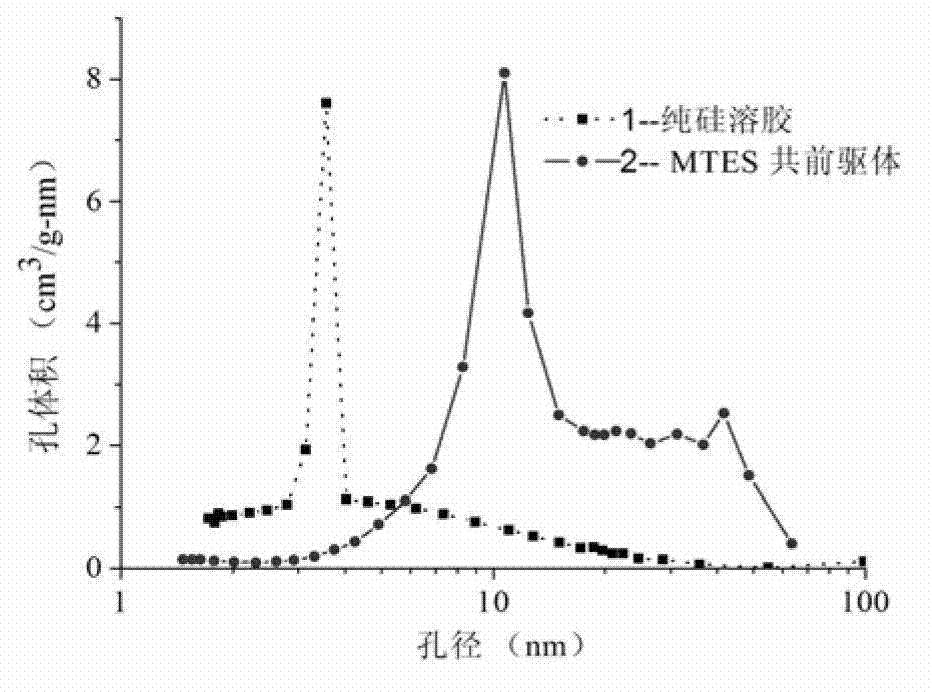

A technology of silica and airgel, applied in the field of airgel, can solve the problems of poor mechanical strength, high cost, and long synthesis cycle, and achieve the effect of good blockability, low cost, and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The molar ratio of raw materials is: water glass: MTES: water=1: 0.3: 35, the MTES of 1.7ml, the water glass solution of 5ml and the deionized water of 12.5ml are mixed and stirred for 48h, and then the mixed solution is passed into 25ml of strong acid In the styrene resin, after 10 minutes, the silica sol with pH = 2~3 was obtained by suction filtration, and a certain amount of ammonia water was added while stirring, so that the final pH value of the system was 8.0. After 10 minutes, the stirring was stopped, and the SiO 2 The sol was allowed to stand for 24 hours until the sample gelled. Put the gel in absolute ethanol solution for aging and solvent replacement. The aging temperature is 30°C. After aging, the gel sample is immersed in the solution. The volume ratio of the ingredients is trimethylchlorosilane (TMCS): absolute ethanol: n-hexane =1 (4ml): 1:8 mixed solution modified for 2 days, the modified solution was washed away with n-hexane, and the sample was soake...

Embodiment 2

[0045]The molar ratio of raw materials is: water glass: MTMS: water=1: 0.3: 38, the MTMS of 1.7ml, the water glass solution of 5ml and the deionized water of 13.5ml are mixed and stirred for 24h, and then the mixed solution is passed into 25ml of strong acid In the styrene resin, filter the silica sol with pH=2~3 after 10 minutes, and add a certain amount of ammonia water while stirring, so that the final pH value of the system is about 8.0. After 10min, the stirring was stopped, and the SiO 2 The sol was allowed to stand for 24 hours until the sample gelled. Put the gel in absolute ethanol solution for aging and solvent replacement. The aging temperature is 30°C. After aging, the gel sample is immersed in the solution. The volume ratio of ingredients is TMCS: absolute ethanol: n-hexane = 1 (4ml): 3 : 6 in the mixed solution of modification for 2 days, wash off the modified solution with n-hexane, soak the sample in normal hexane and dry it under normal pressure, and the dryi...

Embodiment 3

[0048] Raw material molar ratio is: water glass: MTES: water=1: 0.2: 40, the MTES of 2.3ml, the water glass solution of 5ml and the deionized water of 14.3ml are mixed and stirred for 24h, then the mixed solution is passed into 25ml of strongly acidic benzene In the vinyl resin, after 10 minutes, suction filter to obtain the silica sol with pH=2~3, and add a certain amount of ammonia water while stirring, so that the final pH value of the system is about 8.0. After 10min, the stirring was stopped, and the SiO 2 The sol was allowed to stand for 24 hours until the sample gelled. Put the gel in absolute ethanol solution for aging and solvent replacement. The aging temperature is 30°C. After aging, the gel sample is immersed in the solution. The volume ratio of ingredients is TMCS: absolute ethanol: n-hexane = 1 (4ml): 1 : 8 in the mixed solution modified for 2 days, the modified solution was washed away with n-hexane, the sample was soaked in normal hexane and dried under normal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com