Catalytic cracking catalyst, preparation and application thereof

A catalytic cracking and catalyst technology, used in catalytic cracking, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve the problems of inability to supplement silicon and limited aluminum extraction, and achieve improved coke selectivity, increased liquid yield, zeolite The effect of strong cracking ability of macromolecules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

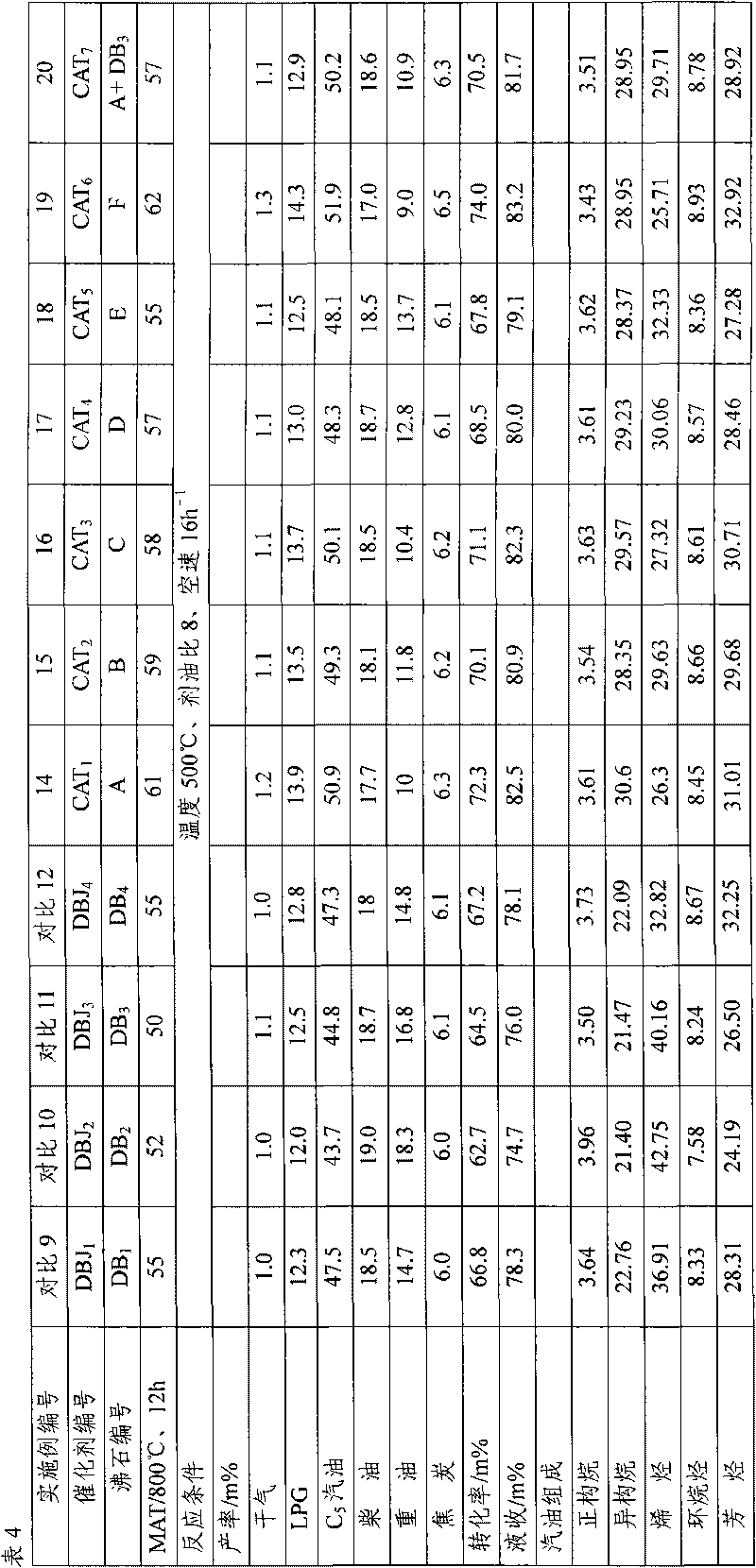

Examples

preparation example Construction

[0031] In the catalyst preparation method provided by the present invention, the mixing and beating of REUSY zeolite with high silicon-aluminum ratio and inorganic oxide binder and spray drying can be carried out according to existing methods, for example, according to the methods disclosed in patents CN97120271.0 and ZL200410029876.5 conduct. It usually includes steps such as mixing zeolite with a substrate, beating to prepare a slurry, and then spray-drying the slurry to form a shape. The catalyst obtained after spray-drying can also be washed, dried, and roasted. These preparation steps are well known to those skilled in the art, and the present invention has no special Require.

[0032] In the catalyst application method provided by the present invention, the catalytic cracking conditions are well known to those skilled in the art, and there is no special requirement in the present invention. The heavy oils are, for example, vacuum gas oil, atmospheric residue, vacuum res...

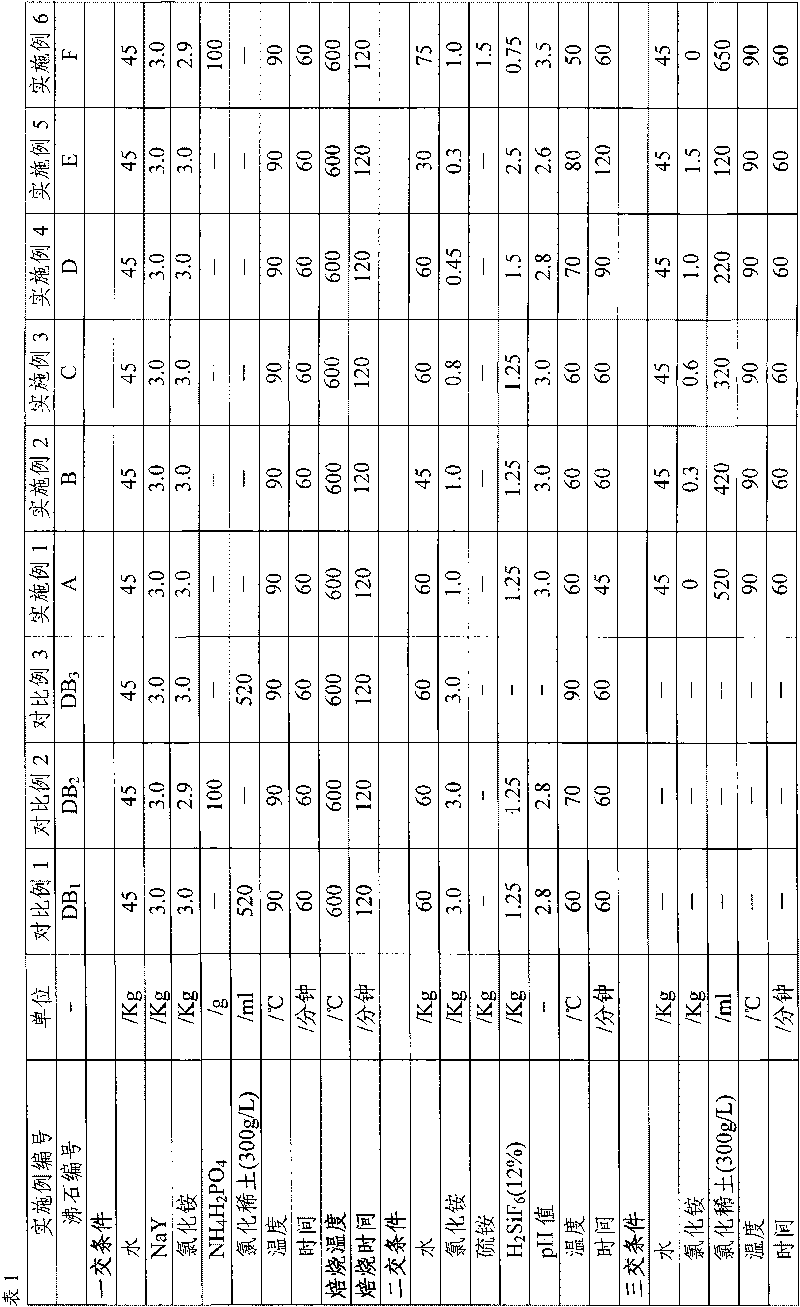

Embodiment 1

[0036] This example illustrates the preparation of the high-silicon-aluminum ratio rare earth ultrastable Y zeolite of the present invention.

[0037] Get 3 kilograms (dry basis) NaY zeolite (Sinopec Catalyst Qilu Branch Company produces, NaY 2 O 14% by weight, relative crystallinity 90%, unit cell constant 2.465nm), after beating with 45 kilograms of decationized water, add 3.0 kilograms of NH 4 Cl, heat up to 90°C, carry out ion exchange for 60 minutes, filter and wash with water, and roast the filter cake at 600°C and 100% water vapor for 2 hours to make a calcined zeolite NaHY, whose Na 2 The O content is 4.5% by weight.

[0038] Beat the above NaHY zeolite with 60 kg of decationized water, add 0.3 kg of NH 4 Cl, under stirring, add 12% by weight of fluorosilicic acid solution to make H 2 SiF 6 : Zeolite=0.05, adjust the pH value of the slurry to 3.0 with 3N hydrochloric acid, then heat up to 60°C, react for 45 minutes, filter, wash with water, and make zeolite M 1 . ...

Embodiment 2

[0042] This example illustrates the preparation of the high-silicon-aluminum ratio rare earth ultrastable Y zeolite of the present invention.

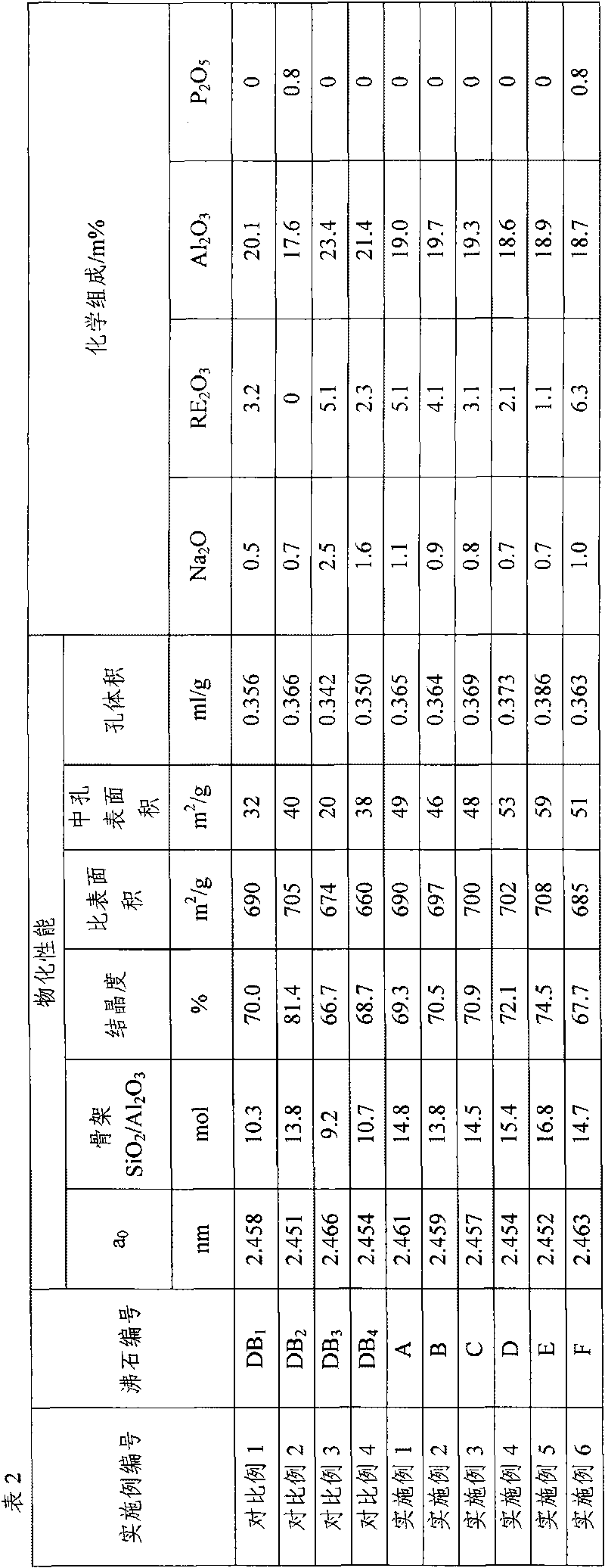

[0043] The preparation method is the same as in Example 1, and the preparation conditions are shown in Table 1, and the rare earth-containing ultrastable Y-type zeolite B is prepared.

[0044] The chemical composition and main physicochemical properties of zeolite B are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cell constant | aaaaa | aaaaa |

| Cell constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com