Method of improving the acrylic rubber sealant compatibility in an internal combustion engine

a technology of acrylic rubber and internal combustion engine, which is applied in the direction of separation process, liquid degasification, foam dispersion/prevention, etc., can solve the problems of resin or rubber sealant deterioration, shrinkage of sealant, and inability to meet the requirements of internal combustion engine performance, etc., to achieve the effect of improving the compatibility of acrylic rubber sealan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

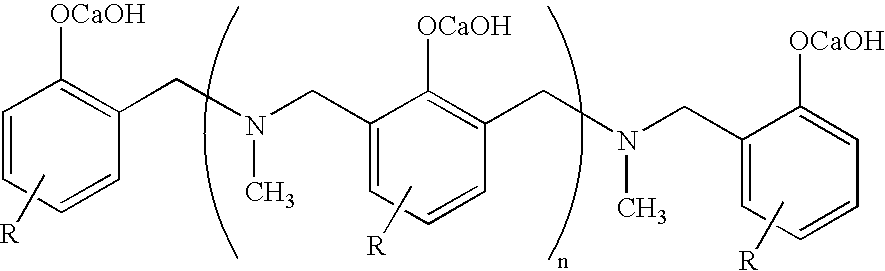

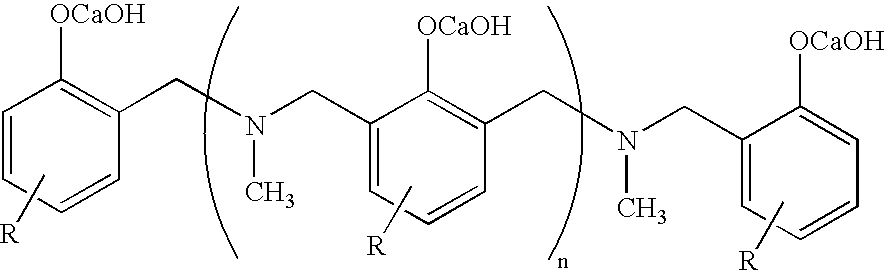

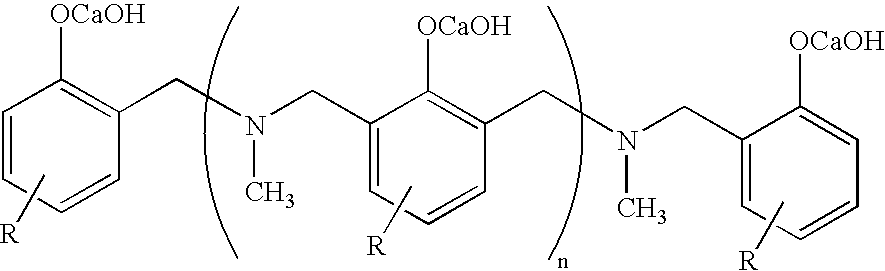

Image

Examples

example 1

[0091] The below-mentioned additives and the base oil of lubricating viscosity were mixed to give: the lubricating oil composition employed in the method of the present invention. The lubricating oil composition was SAE viscosity grade 10W30. Also shown below are the contents of each element (Ca, P, N) in the lubricating oil composition, the ratio between the nitrogen content attributable to all the dispersants and that attributable to the detergent A (Mannich base calcium phenate), and the ratio between the metal content attributable to all the detergents and that attributable to the detergent A (Mannich base calcium phenate). [0092] (1) Additives [0093] Dispersant A (amount: 3.0 wt. %, content in terms of nitrogen: 0.03 wt. %), [0094] Dispersant B (amount. 1.5 wt. %, content in terms of nitrogen: 0.03 wt. %), [0095] Detergent A (amount: 0.4 wt. %, content in terms of calcium: 0.01 wt. %, content in terms of nitrogen; 0.006 wt. %), [0096] Detergent B (amount: 0.86 wt. %, content in...

example 2

[0111] The procedures of Example 1 were repeated except for changing the amount of the detergent A (Mannich base calcium phenate) into 1.16 wt. % (content in terms of calcium: 0.03wt. %, content in terms of nitrogen: 0.018 wt. %) and for changing the residual amount of the base oil of lubricating viscosity so that the total amount of the lubricating oil composition is 100 wt. %. The prepared lubricating oil composition was SAE viscosity grade 10W30. Shown below are the contents of each element (Can P, N) in the lubricating oil composition, a ratio between the nitrogen content attributable to all the dispersants and that attributable to the detergent A (Mannich base calcium phenate), and a ratio between the metal content attributable to all the detergents and that attributable to the detergent A (Mannich base calcium phenate). [0112] (1) Contents of each element (Ca, P, N) in the lubricating oil composition [0113] Calcium (Ca): 0.26 wt. %, Phosphorus (P); 0.10 wt. %, Nitrogen (N): 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| sizes | aaaaa | aaaaa |

| kinematic viscosity | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com