Iron-based metal organic framework (MOFs) photocatalytic material and its preparation method and use

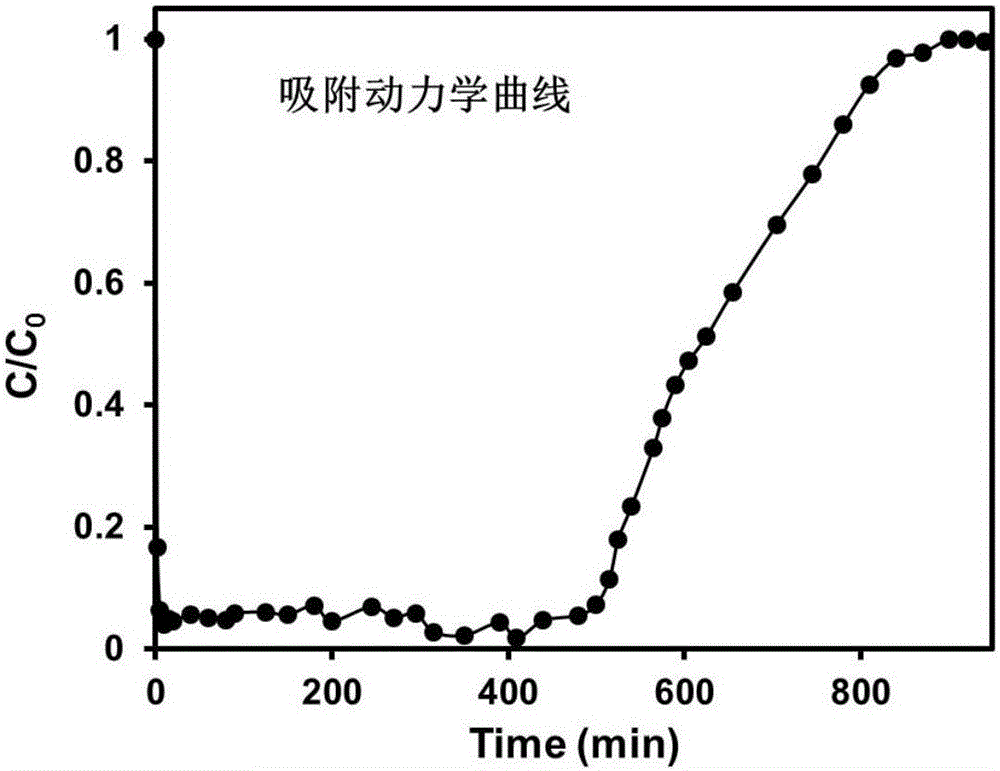

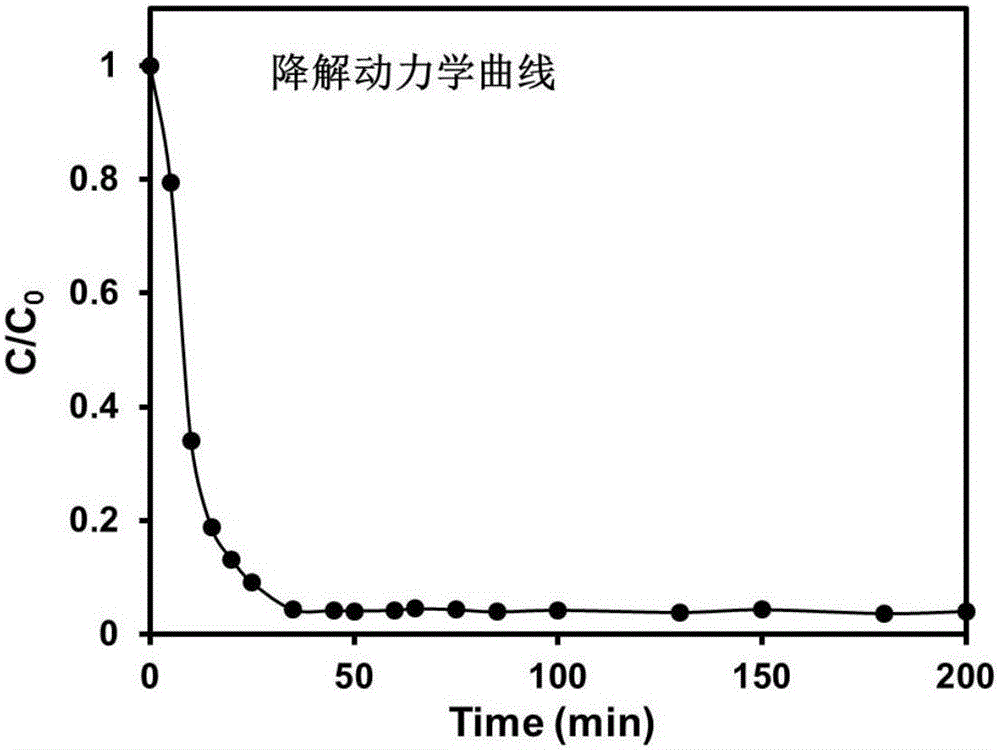

A photocatalytic material, iron-based technology, applied in the field of photocatalysis, can solve the problems of ineffective adsorption of VOCs pollutants, reduced photocatalytic oxidation efficiency, small specific surface area, etc., achieves excellent adsorption and photocatalytic synergy, and is conducive to adsorption and enrichment, the effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] S1. FeCl with a molar ratio of 2:1 3 ·6H 2 O and terephthalic acid were added to 30 mL of DMF solution, stirred at room temperature for 1 h, and an orange-yellow transparent solution was obtained.

[0030] S2. Put the transparent solution obtained in step S1 into a 100mL hydrothermal reactor and react at 110°C for 24h; after cooling to room temperature at a cooling rate of 0.1°C / min, collect the precipitate to obtain an iron-based MOFs photocatalytic material crude products.

[0031] S3. Soak the precipitate obtained in step S2 in ethanol solution, soak at 60°C for 15h, and obtain solid powder in the solution by filtration; vacuum dry at 150°C for 12h to obtain an activated iron-based MOFs photocatalytic material.

Embodiment 2

[0033] S1. FeCl with a molar ratio of 1:1 3 ·6H 2 O and terephthalic acid were added to 30mL DMF solution, stirred at room temperature for 2h, and an orange-yellow transparent solution was obtained.

[0034] S2. Put the transparent solution obtained in step S1 into a 100mL hydrothermal reactor and react at 150°C for 20h; after cooling to room temperature at a cooling rate of 0.5°C / min, collect the precipitate to obtain an iron-based MOFs photocatalytic material crude products;

[0035] S3. Soak the precipitate obtained in step S2. in ethanol solution, soak at 60°C for 15h, and obtain solid powder in the solution by filtration; vacuum-dry at 120°C for 15h to obtain an activated iron-based MOFs photocatalytic material.

Embodiment 3

[0037] S1. FeCl with a molar ratio of 2:1 3 ·6H 2 O and terephthalic acid were added to 30mL DMF solution, stirred at room temperature for 1.5h, and an orange-yellow transparent solution was obtained.

[0038] S2. Put the transparent solution obtained in step S1 into a 100mL hydrothermal reactor and react at 150°C for 24h; after cooling to room temperature at a cooling rate of 1.0°C / min, collect the precipitate to obtain an iron-based MOFs photocatalytic material crude products.

[0039]S3. Soak the precipitate obtained in step S2. in ethanol solution, soak at 80°C for 12h, and obtain the solid powder in the solution by filtering; vacuum-dry at 150°C for 12h to obtain the activated iron-based MOFs photocatalytic material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com