Method for preparing acetophenone by biomimetic catalytic oxidation of ethylbenzene with oxygen

A technology of oxygen oxidation and biomimetic catalysis, applied in the preparation of carbon-based compounds, chemical instruments and methods, preparation of organic compounds, etc., can solve problems such as increased operating costs, energy waste, and reduced safety, and achieve the effect of safety in the production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

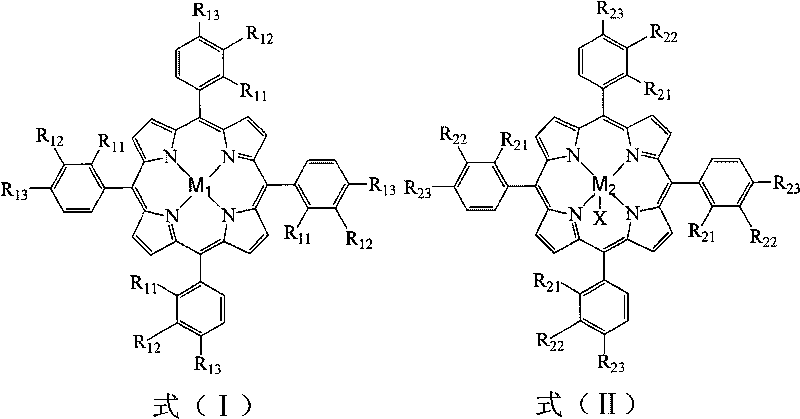

[0044] In a 100mL three-necked flask, add 10.572g ethylbenzene, 1ppm (0.07mg) tetraphenyliron porphyrin (that is, R in formula (I) 11 for hydrogen, R 12 for hydrogen, R 13 is hydrogen, M 1 is iron), 10ppm (0.86mg) four-(p-chlorophenyl) cobalt porphyrin (that is, R in the general formula (I) 11 for H, R 12 for H, R 13 for Cl, M 1 For Co), oxygen was introduced at a flow rate of 40 mL / min, the reaction was initiated at 130°C, and the reaction was carried out at 90°C for 6h. The reacted mixture was distilled under reduced pressure to obtain acetophenone, the conversion rate of ethylbenzene was 81.3%, the yield of acetophenone was 73.6%, and the purity was 99.7%.

Embodiment 2

[0046] In a 100mL three-necked flask, add 10.595g ethylbenzene, 5ppm (0.38mg) tetra-phenylmanganese porphyrin chloride (that is, R in general formula (II) 21 for H, R 22 for H, R 23 for H, M 2 is Mn, X is Cl), 5ppm (0.44mg) tetrakis-(o-methoxyphenyl) cobalt porphyrin chloride (that is, R in the general formula (II) 21 for OCH 3 , R 22 for H, R 23 for H, M 2 is Co, X is Cl), oxygen was introduced at a flow rate of 40 mL / min, the reaction was initiated at 130°C, and the reaction was carried out at 90°C for 7h. The reacted mixture was distilled under reduced pressure to obtain acetophenone, the conversion rate of ethylbenzene was 82.4%, the yield of acetophenone was 73.8%, and the purity was 99.2%.

Embodiment 3

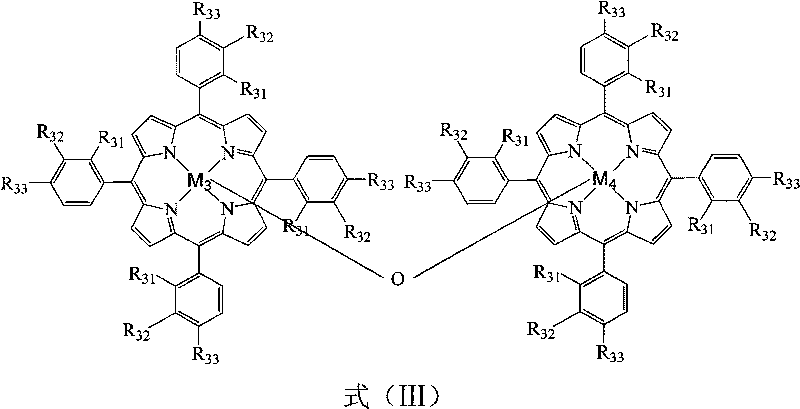

[0048] In a 100mL three-necked flask, add 10.582g ethylbenzene, 1ppm (0.15mg) μ-oxygen-binuclear tetra-phenyliron porphyrin (that is, R in general formula (III) 31 for H, R 32 for H, R 33 for H, M 3 , M 4 Fe), 5ppm (0.88mg) μ-oxygen-binuclear four-(p-chlorophenyl) cobalt porphyrin (that is, R in the general formula (III) 31 for H, R 32 for H, R 33 for Cl, M 3 , M 4 For Co), oxygen was introduced at a flow rate of 50 mL / min, the reaction was initiated at 130°C, and the reaction was carried out at 80°C for 7h. The reacted mixture was distilled under reduced pressure to obtain acetophenone, the conversion rate of ethylbenzene was 69.5%, the yield of acetophenone was 62.3%, and the purity was 99.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com