Double-component epoxy resin pouring sealant

A technology of epoxy resin and potting glue, which is applied in the field of electronic information, can solve the problems that it is difficult to meet the packaging requirements of high-power electronic modules, cannot meet the packaging requirements of high-power electronic modules, and the tensile strength is reduced, so as to avoid the decline of thermal conductivity , Improve the interface contact state, improve the effect of thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

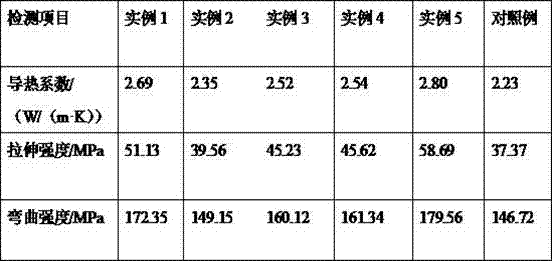

Examples

example 1

[0027] First, take 20 parts of silicon carbide with a particle size of 8 μm, 30 parts of aluminum oxide with a particle size of 30 μm, and 20 parts of aluminum nitride with a particle size of 80 μm in the order of parts by weight, and stir and mix at a speed of 400 r / min in a mixer 2h, get particle filler; then take 80 parts of epoxy resin, 20 parts of thinner, 10 parts of fibrous filler, 10 parts of sheet filler, 8 parts of particle filler, 1 part of dispersant, 1 part of Degassing agent, stir and mix epoxy resin, diluent, dispersant and defoaming agent for 30 minutes, then add fibrous filler, sheet filler and granular filler in turn, and disperse for 1 hour with a high-speed disperser, and then undergo vacuum degassing to obtain A component; again by weight, take 80 parts of curing agent, 8 parts of dibutyl phthalate, 0.6 part of DMP-30 epoxy accelerator, 10 parts of hydrotalcite, 1 part of dispersant, 1 part of Degassing agent, stir and mix curing agent, dibutyl phthalate, ...

example 2

[0029]First, mix magnesium aluminum hydrotalcite with deionized water at a mass ratio of 1:50, then ultrasonically disperse for 38 minutes at an ultrasonic frequency of 43kHz, and then add 0.4 times the mass of magnesium aluminum hydrotalcite to the deionized water Sodium dodecylbenzene sulfonate, followed by stirring and reacting at a constant temperature for 4 hours at a temperature of 60°C and a rotating speed of 500r / min, and then filtered, washed and dried to obtain a modified hydrotalcite; in parts by weight, Take 30 parts of silicon carbide with a particle size of 9 μm, 35 parts of alumina with a particle size of 40 μm, and 25 parts of aluminum nitride with a particle size of 90 μm in a mixer, and stir and mix at a speed of 500 r / min for 3 hours to obtain a granular filler; then In parts by weight, take 90 parts of epoxy resin, 25 parts of diluent, 9 parts of particle filler, 2 parts of dispersant, 2 parts of defoamer, and stir epoxy resin, diluent, dispersant and defoam...

example 3

[0031] First, mix magnesium aluminum hydrotalcite with deionized water at a mass ratio of 1:45, then ultrasonically disperse for 36 minutes at an ultrasonic frequency of 41kHz, and then add 0.3 times the mass of magnesium aluminum hydrotalcite to the deionized water Sodium dodecylbenzene sulfonate, followed by stirring and reacting at a constant temperature for 3 hours at a temperature of 58°C and a rotational speed of 450r / min, and then filtered, washed and dried to obtain a modified hydrotalcite; then calculated in parts by weight , take 85 parts of epoxy resin, 22 parts of diluent, 11 parts of fibrous filler, 1 part of dispersant, 2 parts of defoamer, stir and mix epoxy resin, diluent, dispersant and defoamer for 33 minutes, and then Add fibrous filler, disperse with a high-speed disperser for 1 hour, and then undergo vacuum defoaming to obtain component A; then take 85 parts of curing agent, 9 parts of dibutyl phthalate, and 0.6 part of DMP in order by weight. -30 epoxy ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com