Titanium-base tubular ruthenium dioxide coating membrane electrode and preparation method thereof

A technology of ruthenium dioxide and oxide coating, which is applied in the coating, metal material coating process, liquid chemical plating, etc., can solve the problems of high energy consumption in electrode treatment and poor effect of high-concentration wastewater, and achieve improved Efficiency, increased contact probability, and increased specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The preparation method of titanium-based tubular ruthenium dioxide coating film electrode, it comprises the steps:

[0025] The first step: the preparation of the alkoxide solution of ruthenium metal

[0026] Accurately weigh RuCl 3 ·3H 2 O 20g in a beaker, then add 1L of isopropanol to the beaker, then add 0.5mol of hydrochloric acid, stir until RuCl 3 ·3H 2 O was completely dissolved in isopropanol to prepare a ruthenium metal alkoxide solution.

[0027] Step 2: Preparation of titanium-based tubular ruthenium dioxide-coated membrane electrodes by brush coating and thermal oxidation

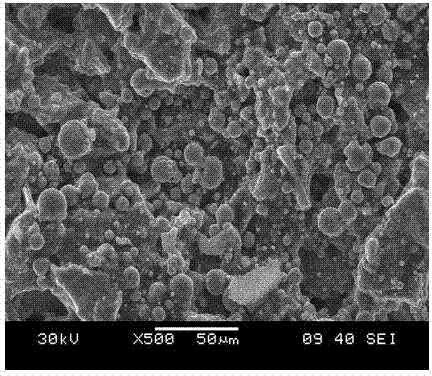

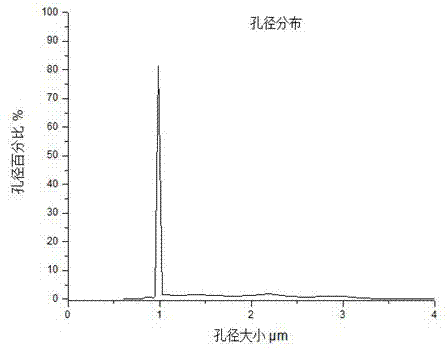

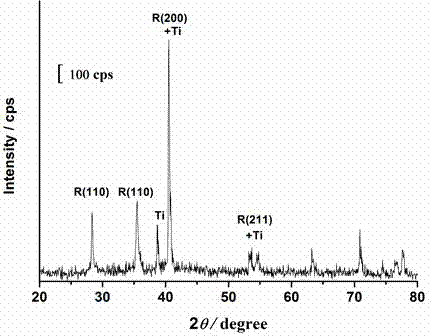

[0028] Preparation of titanium-based tubular ruthenium dioxide coating: first, the existing tubular titanium substrate (the tubular titanium substrate is a tubular structure with the substrate closing the top opening, the tube wall is covered with micropores, and the diameter of the micropores is 0.5~ 4 μm) were washed with distilled water and dried in an oven. Then brush the prepar...

Embodiment 2

[0030] The preparation method of titanium-based tubular ruthenium dioxide coating film electrode, it comprises the steps:

[0031] The first step: the preparation of the alkoxide solution of ruthenium metal

[0032] Accurately weigh RuCl 3 ·3H 2 Put 23.4g of O in a beaker, then add 1L of isopropanol to the beaker, add 0.5mol of hydrochloric acid, stir until RuCl 3 ·3H 2 O was completely dissolved in isopropanol to prepare a ruthenium metal alkoxide solution.

[0033] Step 2: Preparation of titanium-based tubular ruthenium dioxide-coated membrane electrodes by brush coating and thermal oxidation

[0034] Preparation of titanium-based tubular ruthenium dioxide coating: first, the existing tubular titanium substrate (the tubular titanium substrate is a tubular structure with the substrate closing the top opening, the tube wall is covered with micropores, and the diameter of the micropores is 0.5~ 4 μm) were washed with distilled water and dried in an oven. Then brush th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com