Matching method based on physical form of tobacco shred

A technology of physical form and shredded tobacco, which is applied in the fields of tobacco, tobacco preparation, food science, etc., can solve the problem of uniformity of shredded tobacco mixing, does not consider the problem of matching different lengths of shredded tobacco, and can not solve the problem of cigarette rolls well Problems such as the control of physical indicators, etc., to achieve good application prospects, improve blending uniformity, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

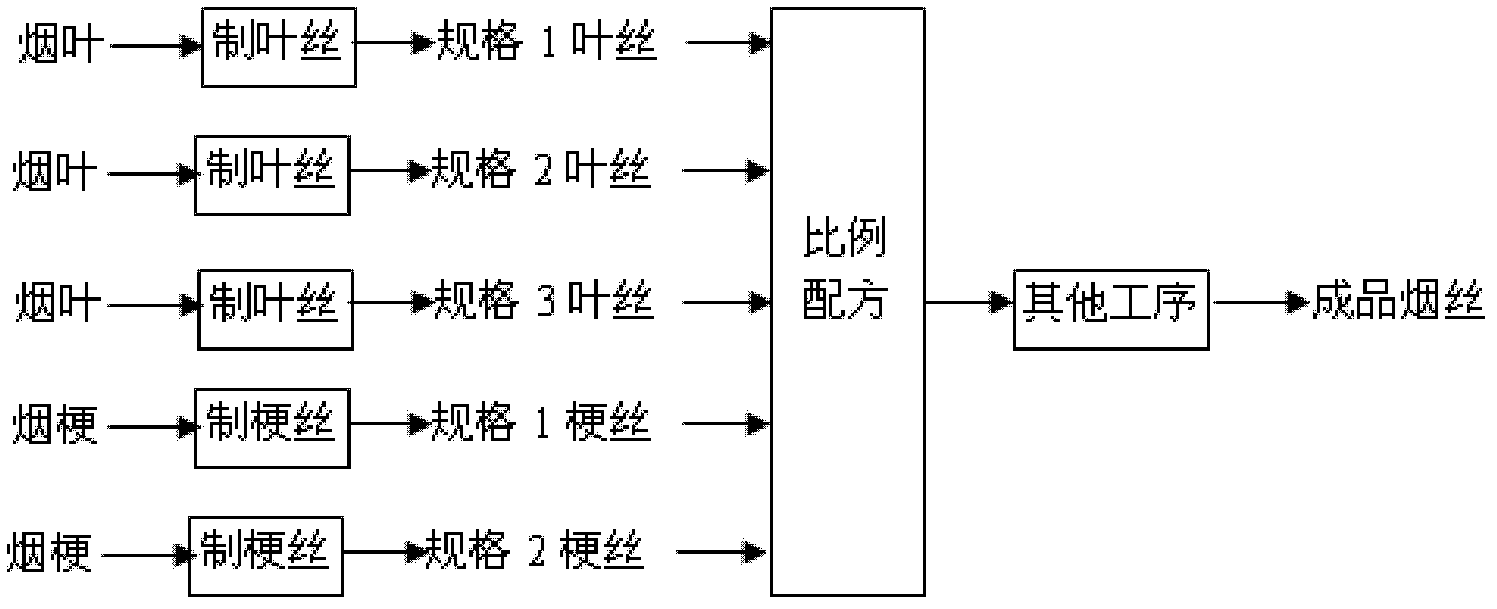

[0017] Through the shredded process, according to the size of the tobacco leaves and the length of the tobacco stems, according to the figure 1 As shown, shredded leaves and shredded stems are processed into the following specifications respectively:

[0018] Specification 1 leaf silk: length between 25mm-15mm, width between 0.7mm-1.0mm.

[0019] Specification 2 leaf silk: length between 20mm-10mm, width between 1.0mm-3.0mm.

[0020] Specification 3 leaf silk: the length is less than 10mm, and the width is between 2.0mm-4.0mm.

[0021] Specification 1. Shredded stem: the length is more than 20mm.

[0022] Specification 2 stems: the length is less than 20mm.

[0023] After the shredded leaves and cut stems of different length specifications and different width specifications are prepared, they are designed according to the proportion of cigarette formula, and the shredded leaves and cut stems of different length specifications and different width specifications are mixed acc...

Embodiment 2

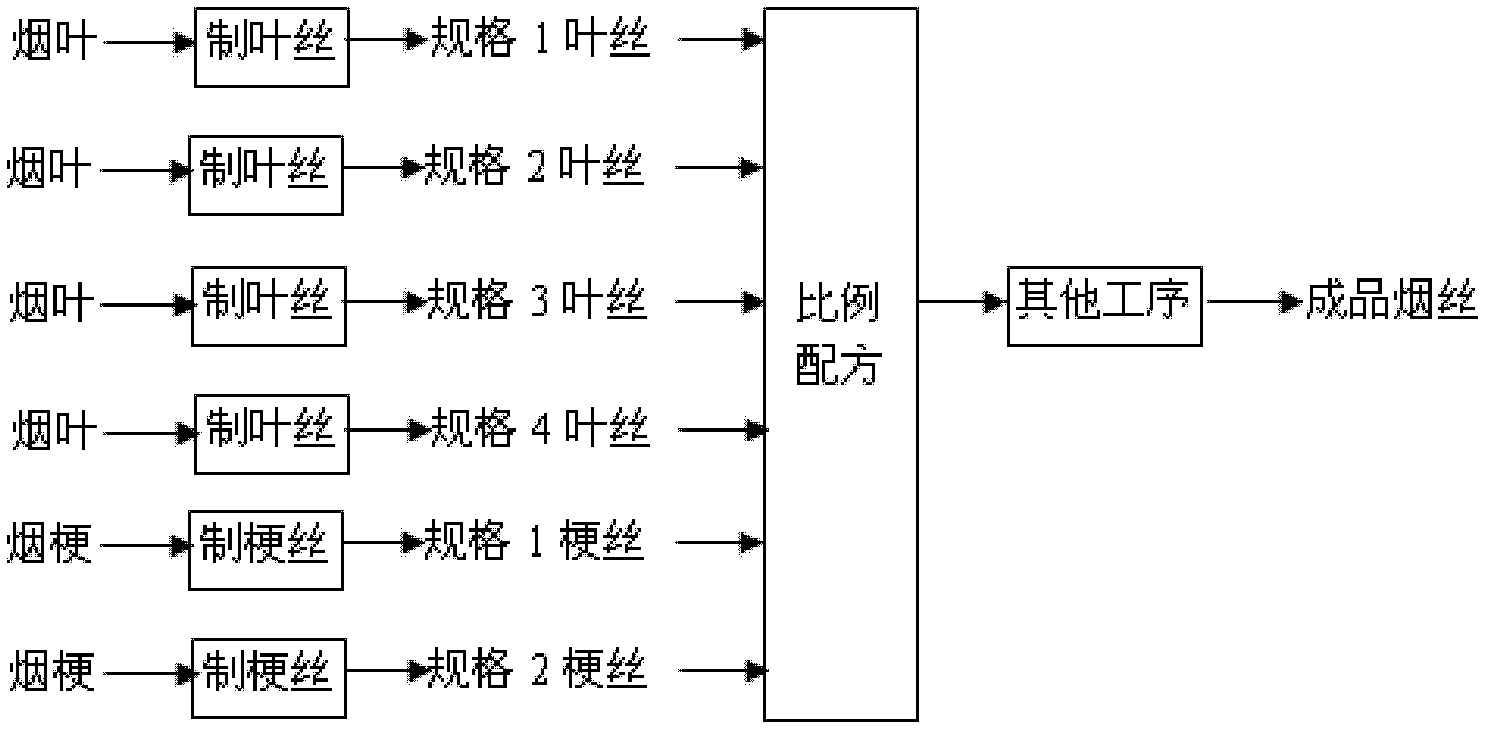

[0026] Such as figure 2 As shown, through the silk-making process, according to the size of the tobacco leaves and the length of the tobacco stems, the shredded leaves and stems are processed into the following specifications:

[0027] Specification 1 leaf silk: length between 25mm-15mm, width between 0.7mm-1.0mm.

[0028] Specification 2 leaf silk: length between 20mm-10mm, width between 1.0mm-3.0mm.

[0029] Specifications 3 leaf silk: length between 15mm-5mm, width between 2.0mm-4.0mm.

[0030] Specifications 4 leaf silk: the length is less than 5mm, and the width is between 3.0mm and 5.0mm.

[0031] Specification 1. Shredded stem: the length is more than 20mm.

[0032] Specification 2 Stem: the length is less than 2mm.

[0033] After the shredded leaves and cut stems of different length specifications and different width specifications are prepared, they are designed according to the proportion of cigarette formula, and the shredded leaves and cut stems of different l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com