Single-duct ejector device for aero-engine

An aero-engine and duct technology, which is applied in the field of multi-nozzle distributed single-duct injection devices with variable working conditions, can solve the problem of inability to change the aerodynamic parameters of the mixed air flow, the inability to change the ejection outlet area, and the low efficiency of high-energy fluid ejection To achieve the effect of improving ejection efficiency and gas mixing uniformity, saving test costs, and improving the quality of the intake air field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

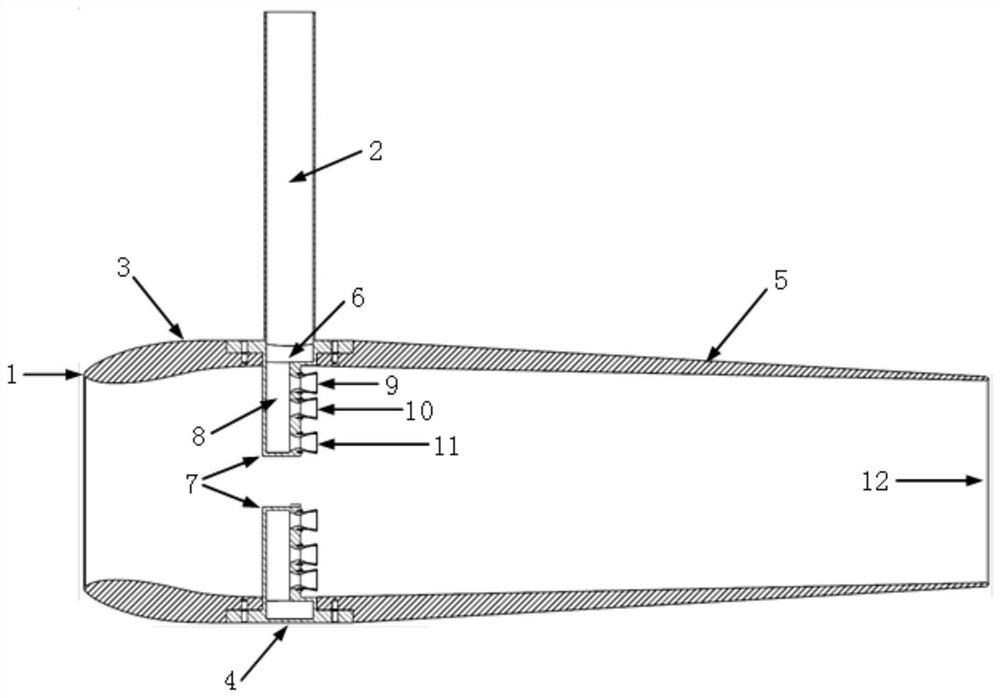

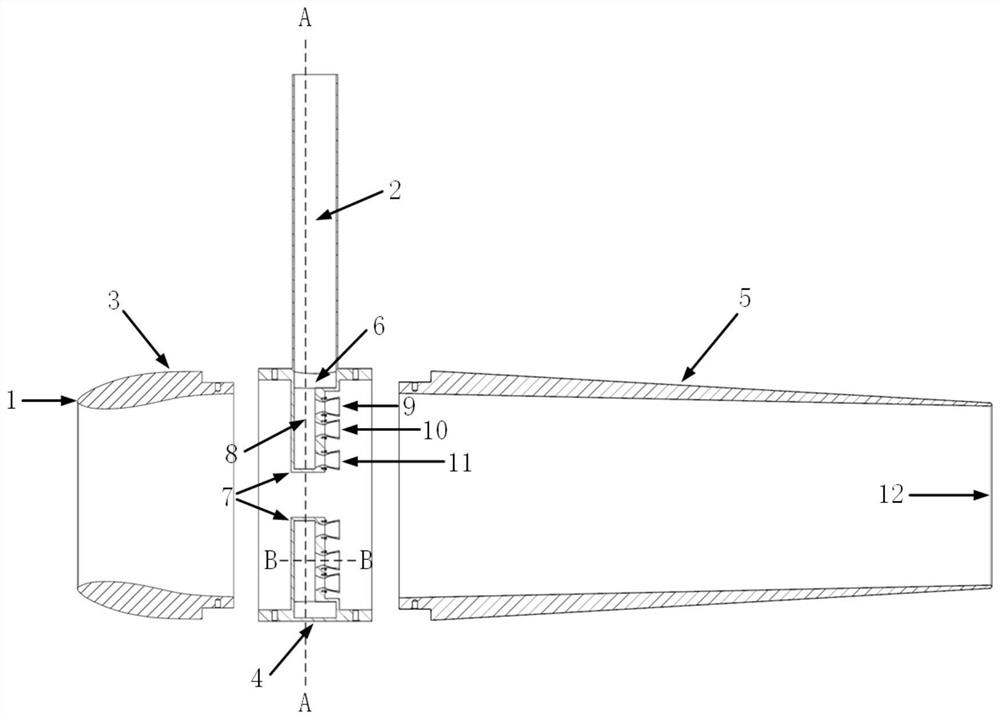

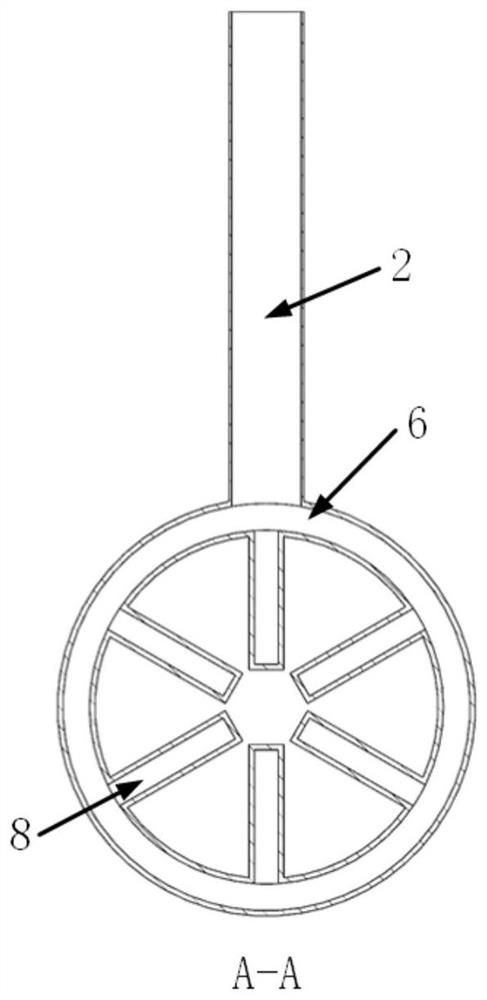

[0035] Single-duct injection device for aero-engine This embodiment is a single-duct injection device for aero-engine, including high-pressure intake pipe 2, ejector, leading edge strut 7 and variable Mach Number of nozzles.

[0036] The ejector is divided into an ejector front section 3 , an ejector middle section 4 and an ejector rear section 5 . There are six stabilizing struts 7, and the air inlet ends of each stabilizing strut are respectively welded to the inner surface of the casing of the middle section 4 of the ejector, and are connected to the annular high-pressure gas source stationed in the middle section of the ejector. 6 connected. On one surface of each said strut, three variable Mach number nozzles are installed along the length direction of each strut, and according to the position of each variable Mach nozzle on the strut, automatically From the inner surface of the middle section of the ejector to the center of the middle section of the ejector, three rows...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com