Grid seam cooling structure with fishtail-shaped turbulent flow columns

A cooling structure, fishtail-shaped technology, applied in the direction of the stator, engine components, machines/engines, etc., to reduce flow resistance and enhance wall-adherence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

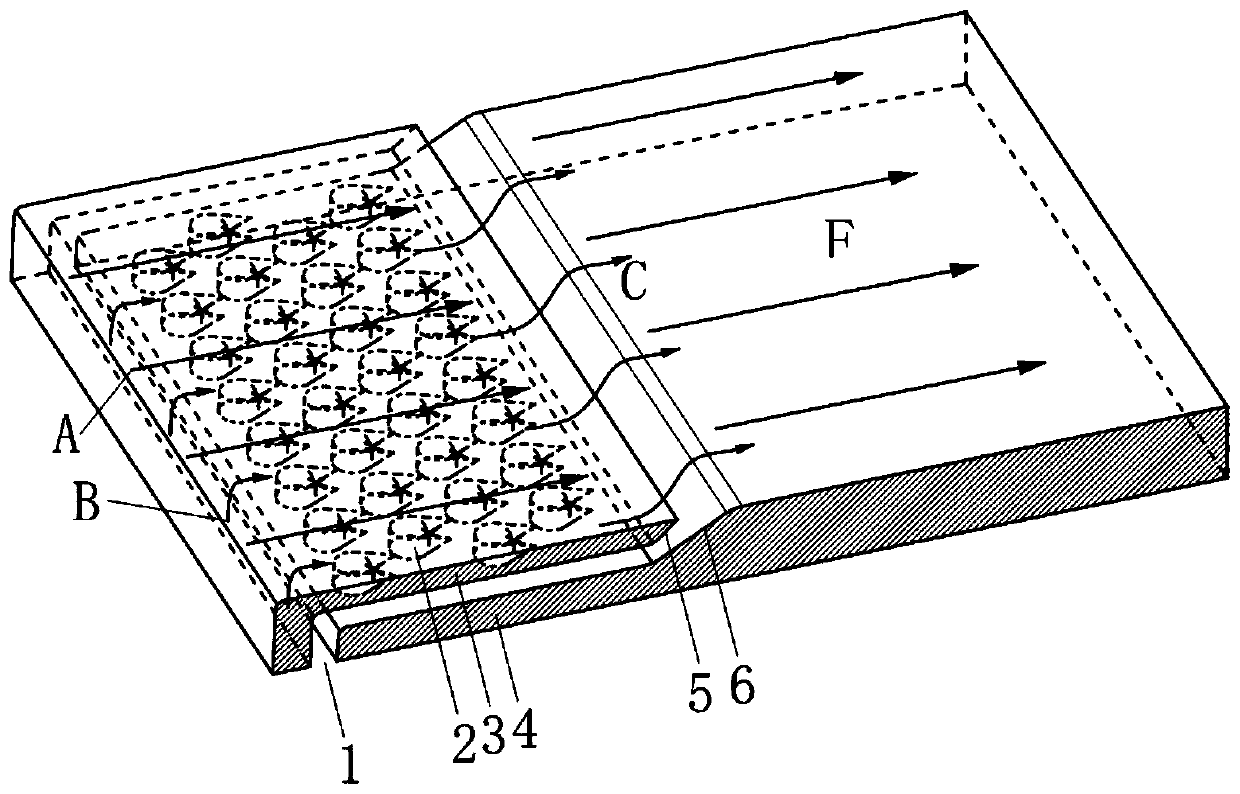

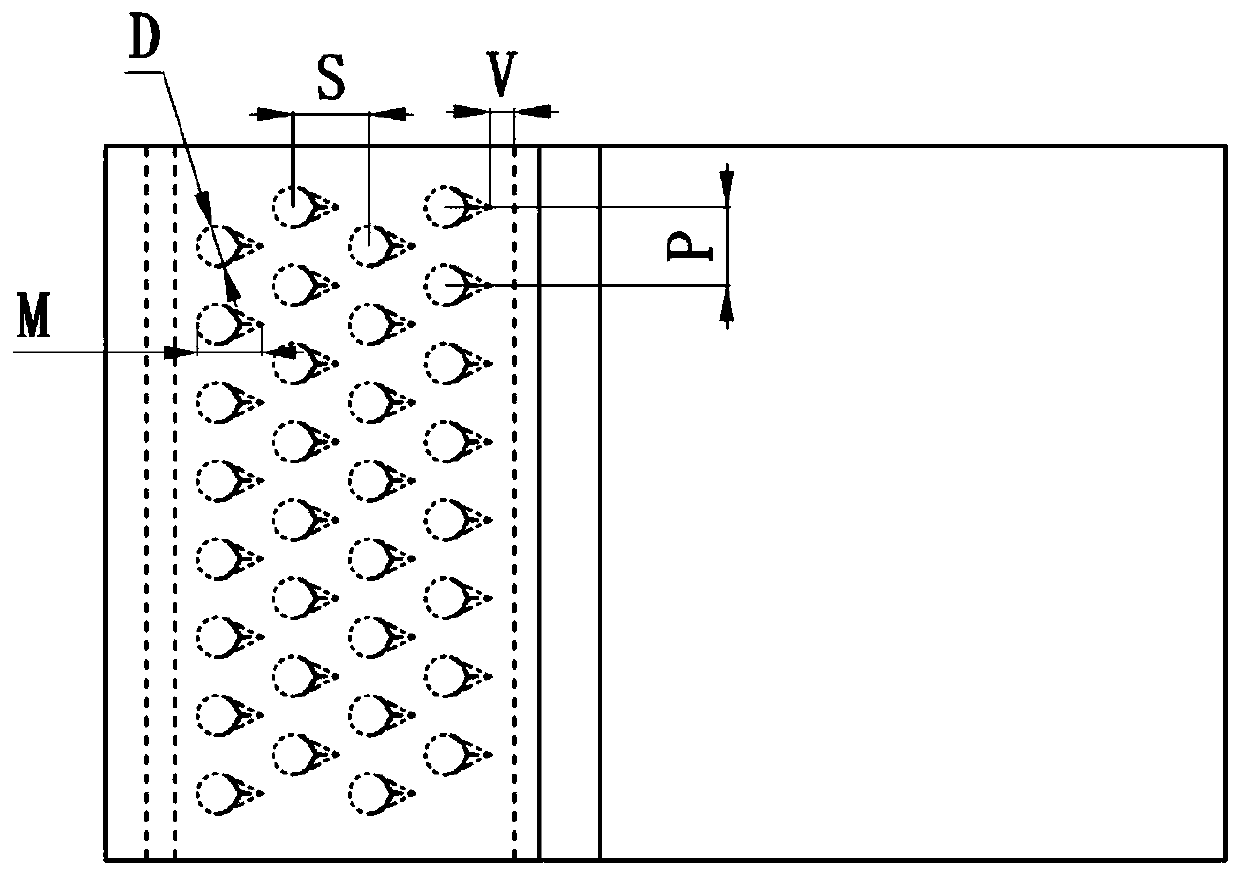

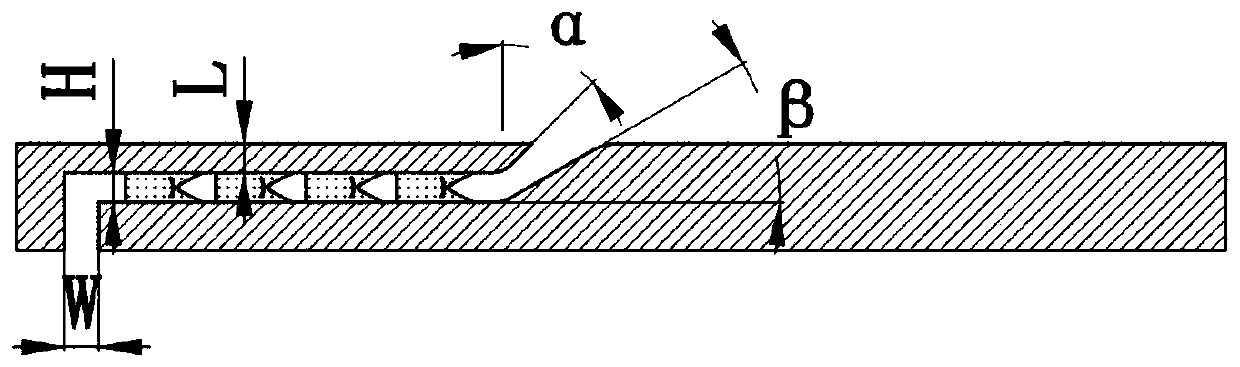

[0029] This embodiment is a grid slot cooling structure with a fishtail-shaped spoiler applied to the turbine guide vane. The air supply cavity 7 and the suction surface grid slot channel 8 are arranged on the suction surface of the turbine blade, provided by the air supply cavity 7. Cold air, the cold air forms an air film at the outlet after passing through the grid slot channel 8 on the suction surface. Among them, four rows of fishtail-shaped spoiler columns are arranged in parallel in the grid slot channel 8 on the suction surface, and the corners of the diversion slope are rounded. In this embodiment, the cylinder diameter D of the fishtail spoiler is 0.8 mm, and the length of the fishtail spoiler along the flow direction is 1.5 mm. The transverse spacing P of the fishtail spoilers is 1.6mm, the flow spacing S of the fishtail spoilers is 1.6mm, and the front and rear rows of fishtail spoilers are arranged in parallel. The width W of the air intake cavity is 1.6mm, the h...

Embodiment 2

[0031] This embodiment is a grid slot cooling structure with a fishtail spoiler column applied to the turbine guide vane. The air supply cavity 9 and the pressure surface grid slot channel 10 are arranged on the pressure surface of the turbine blade, provided by the air supply cavity 9. Cold air, the cold air forms an air film at the outlet after passing through the grid slit channel 10 on the pressure surface. Among them, three rows of fishtail-shaped spoiler columns are arranged in the grid slot channel, and the corners of the outlet diversion slope are rounded. The diameter D of the fishtail spoiler is 1.2 mm, and the length of the fishtail spoiler along the flow direction is 1.8 mm. The transverse pitch P of the fishtail spoiler is 2.0mm, the space between the flow directions S of the fishtail spoiler is 2.0mm, and the fishtail spoilers in the front and rear rows are arranged in fork rows. The width W of the air intake cavity is 2.0mm, the height H of the cold air channel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com