Small furniture surface uniform painting equipment based on furniture manufacturing

A technology for furniture manufacturing and surface uniformity, which is applied to the field of uniform painting equipment on small furniture surfaces, can solve problems such as uneven spraying, damage to protective paint, and low paint quality, and achieves the effect of improving uniformity, good uniformity of paint blending, and improved The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

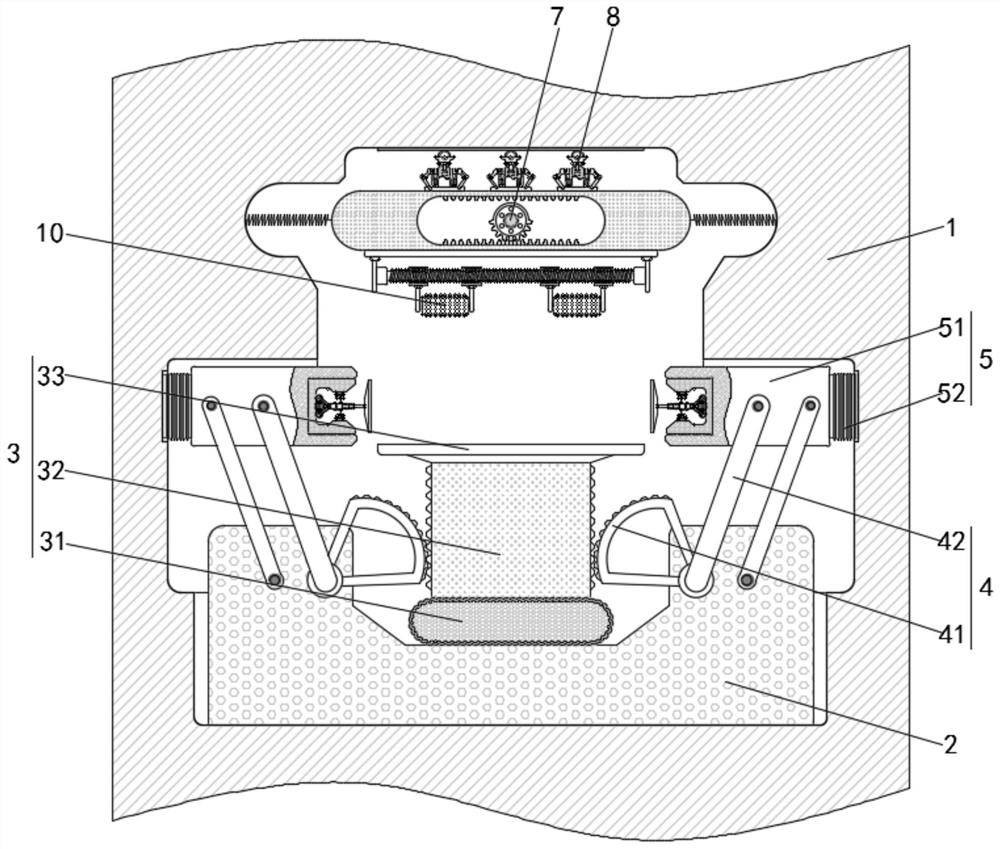

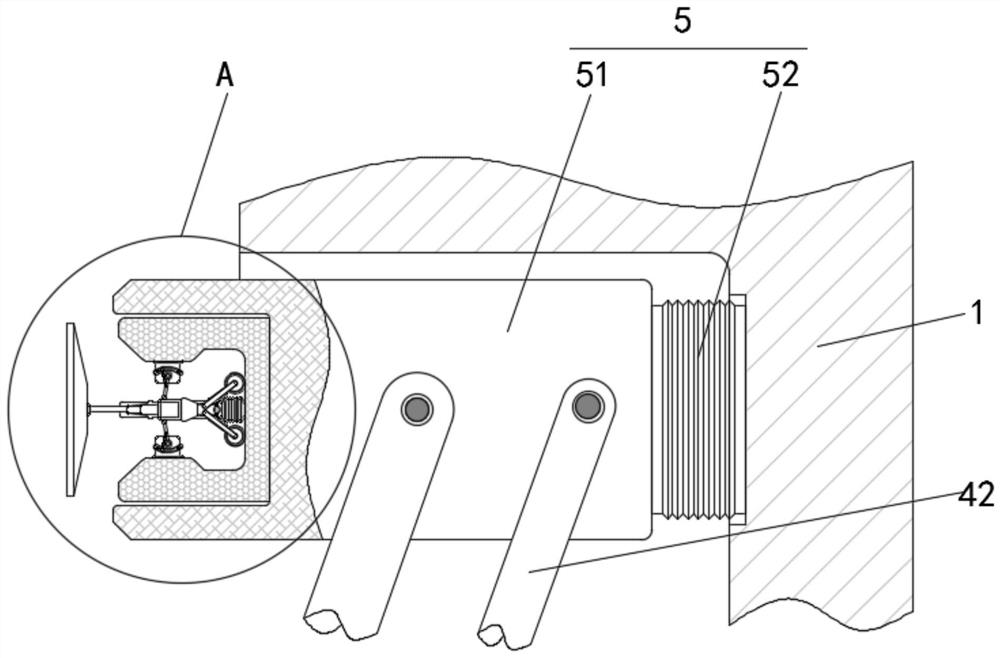

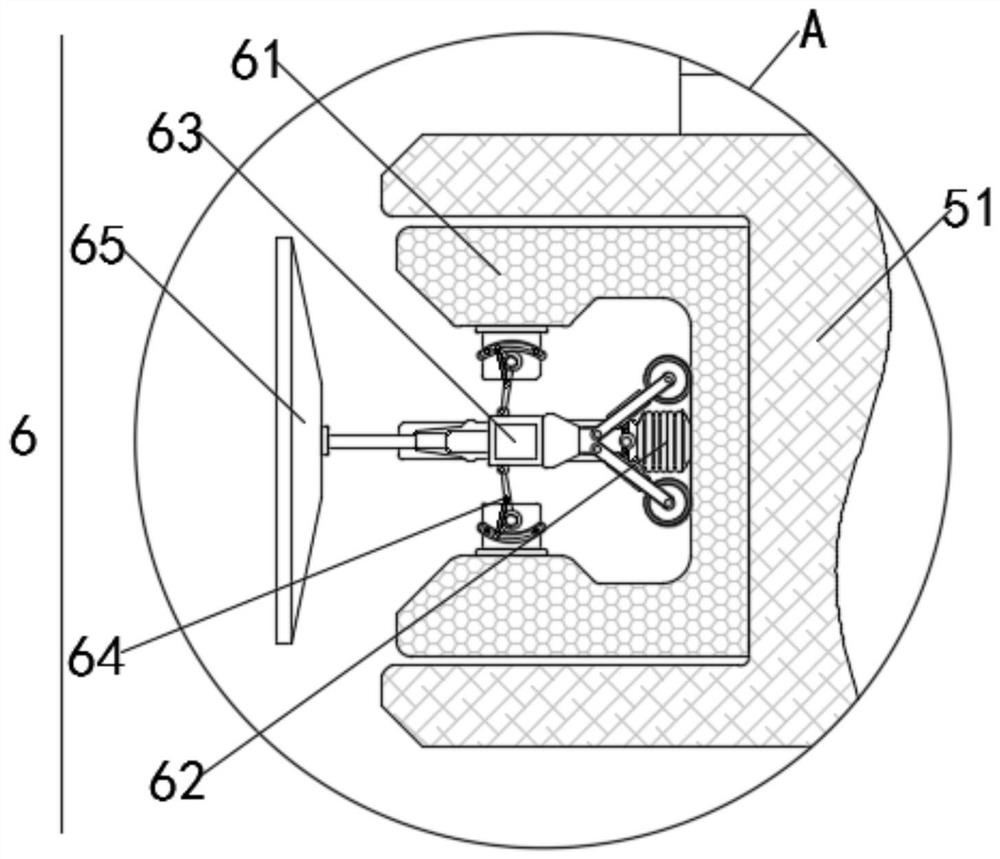

[0031] see Figure 4 with Image 6 with Figure 7 , a small-scale furniture surface uniform painting equipment based on furniture manufacturing, including a main body 1, a driving movable assembly 7 is installed inside the main body 1, a fixed bracket 9 is fixedly installed on the lower side of the driving movable assembly 7, and the fixed bracket 9 The uniform painting assembly 10 is arranged and installed on the lower side of the bottom, and the uniform painting assembly 10 includes an outer shell 101 and an inner shell 102, and a movable shaft 103 is installed on the central axis of the inner shell 102, and an even blade is installed on the outer side of the movable shaft 103. 104, and an absorbent bag 105 is installed between the outer shell 101 and the inner shell 102, and a plurality of uniform nozzles 106 are arranged on the outer side of the outer shell 101.

[0032] Further, the bottom of the inner wall of the main body 1 is fixedly installed with a fixed part 2, an...

Embodiment 2

[0038] see Figure 1 to Figure 7 , a small-scale furniture surface uniform painting equipment based on furniture manufacturing, including a main body 1, a driving movable assembly 7 is installed inside the main body 1, a fixed bracket 9 is fixedly installed on the lower side of the driving movable assembly 7, and the fixed bracket 9 The uniform painting assembly 10 is arranged and installed on the lower side of the bottom, and the uniform painting assembly 10 includes an outer shell 101 and an inner shell 102, and a movable shaft 103 is installed on the central axis of the inner shell 102, and an even blade is installed on the outer side of the movable shaft 103. 104, and an absorbent bag 105 is installed between the outer shell 101 and the inner shell 102, and a plurality of uniform nozzles 106 are arranged on the outer side of the outer shell 101.

[0039] Further, the bottom of the inner wall of the main body 1 is fixedly installed with a fixed part 2, and the upper side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com