Coal mine gas blending device

A technology for coal mine gas and ventilation gas, which is applied in the field of pneumatic blending, can solve the problems of complex engineering site assembly, complex engineering site equipment, large pressure loss in the blending process, etc., to simplify production and processing procedures, improve uniform blending speed, Fast blending effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

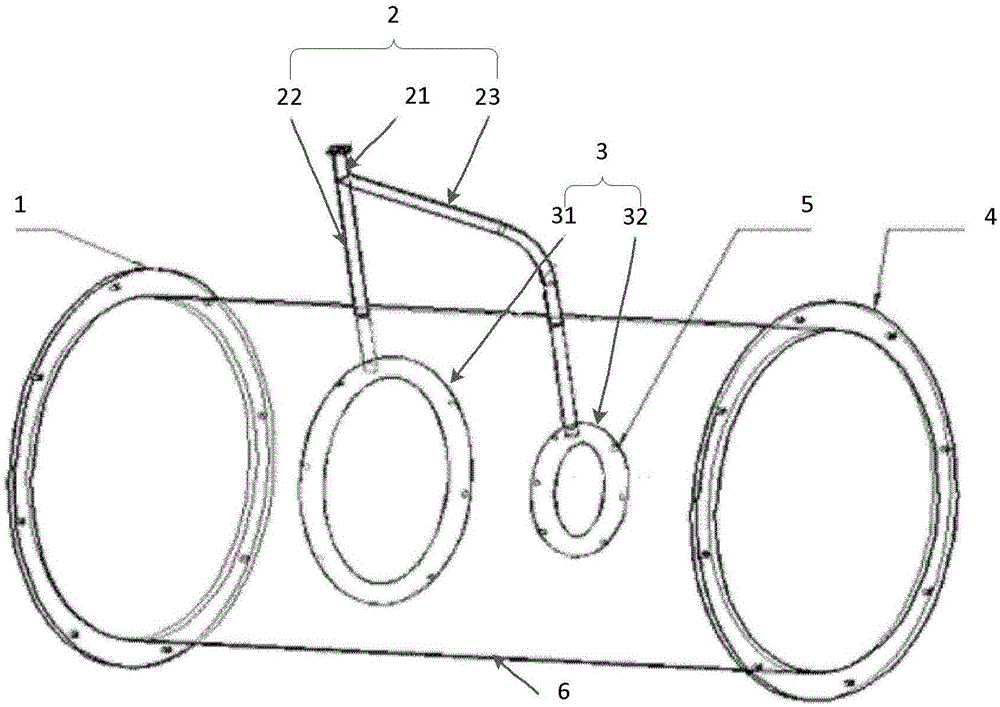

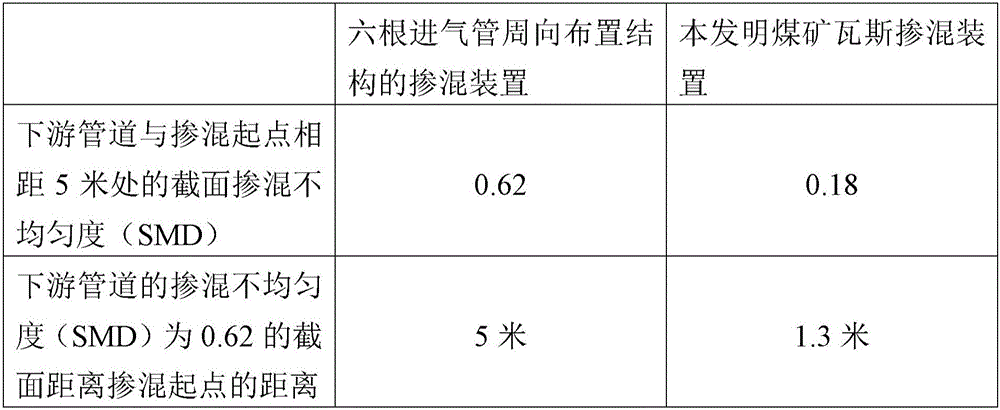

[0019] The purpose of the present invention is to provide a coal mine gas blending device, which can blend the extraction gas into the ventilation gas, and can quickly realize uniform concentration distribution. The device relies on the aerodynamic characteristics of the two gases to achieve mixing without consuming external energy. Relying on the reasonable layout and structure of the annular pipe group and the mixing swirl holes, the resistance loss of the main ventilation gas pipeline during the mixing process is small, and the mixing speed is fast and uniform, which can greatly shorten the mixing distance and ensure the downstream methane concentration detection and flow rate. The accuracy of detection, the stability of the oxidation device and the security of the system. The device is simple in structure, practical in function, easy to process and manufacture, and maintenance-free, and is especially suitable for mixing the gas extracted before the thermal storage oxidatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com