Modified low-resistance tire rubber compound and preparation method thereof

A production method and low-resistance technology, applied in the direction of rolling resistance optimization, road transportation emission reduction, etc., can solve the problems of inability to meet the requirements of low rolling resistance tires, uneven dispersion of carbon black and small materials, and high interface energy between two phases. The effect of delaying the aging reaction of rubber, reducing the coefficient of friction and increasing the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

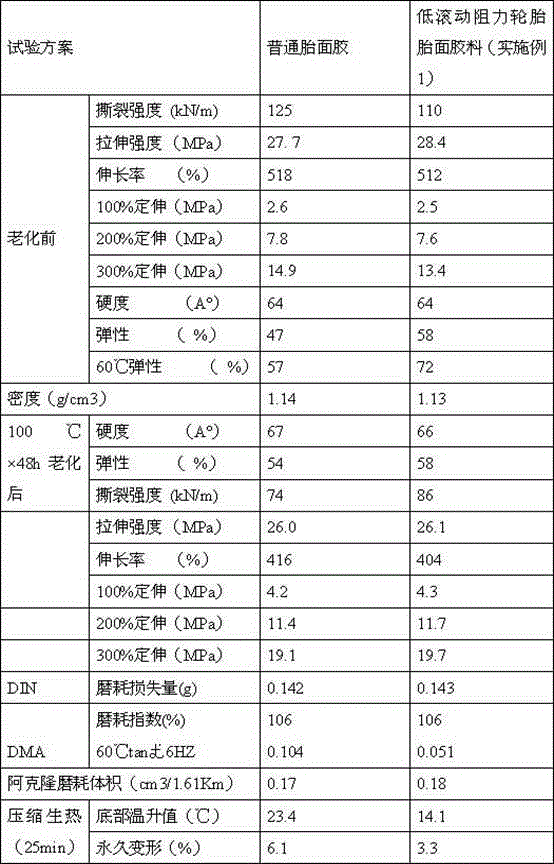

[0018] The present invention will be further described below in conjunction with embodiment:

[0019] The present invention can be realized by the embodiment listed in the following table

[0020] 50-60 parts of natural rubber SIR20, 5-6 parts of styrene-butadiene rubber, 5-6 parts of neoprene rubber, 8-10 parts of N234 carbon black, 7-8 parts of white carbon black, 1-2 parts of silane coupling agent X50S, 2-3 parts of polyethylene glycol, 2-3 parts of toluene diisocyanate, 2-3 parts of tin salt catalyst, 1-2 parts of hydroxyl-terminated polybutadiene, 3-4 parts of softening plasticizer aromatic oil, stearin 2-3 parts of acid, 3-4 parts of anti-aging agent, 1-2 parts of tackifier 204 resin, 1-2 parts of leveling agent UB4000, 1-2 parts of sulfur, 1-2 parts of accelerator TBBS, 0.3- 0.5 servings.

[0021] The aforementioned modified low-resistance tire compound and its preparation method are characterized in that the tin salt catalyst is selected from any one of stannous chlo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com