Automatic double-sided oiling machine

An oiler, double-sided technology, which is applied to devices and coatings that apply liquid to the surface, can solve the problems of sheet wrinkling, waste of materials, mold wear, etc., to save production costs, reduce labor intensity, and avoid easy to wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

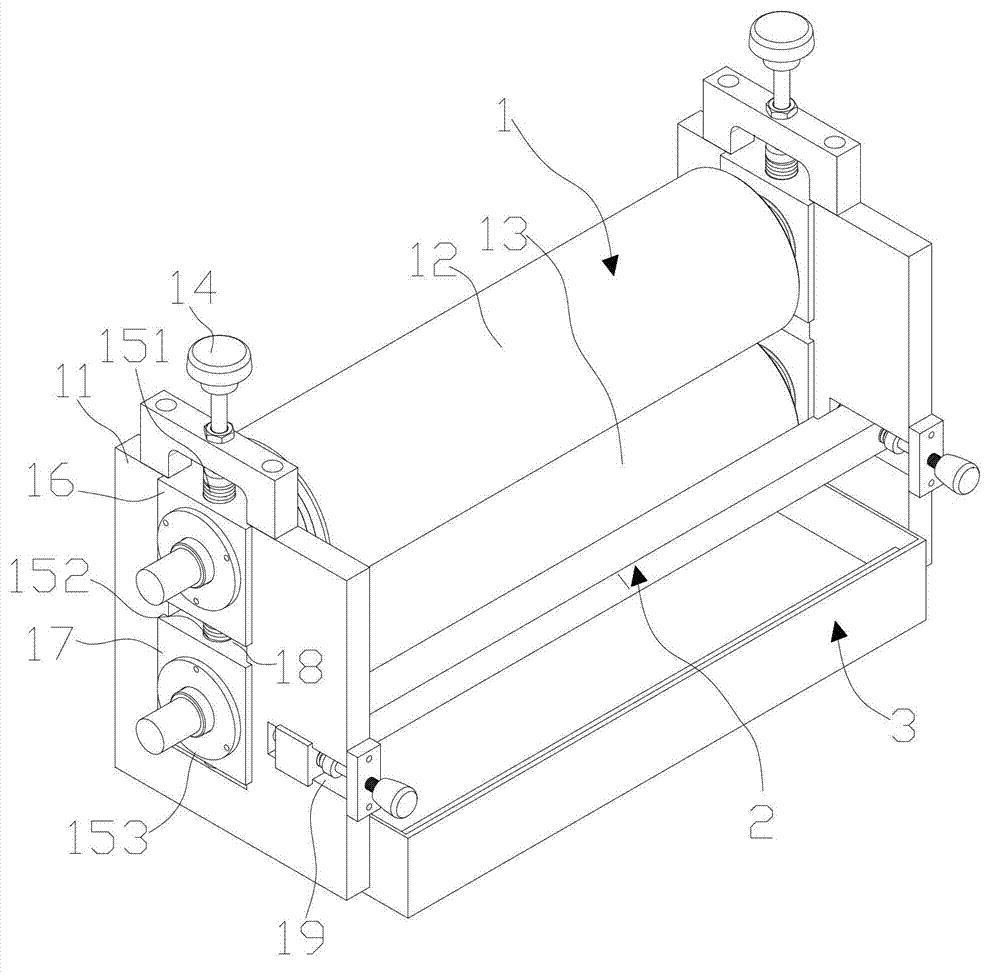

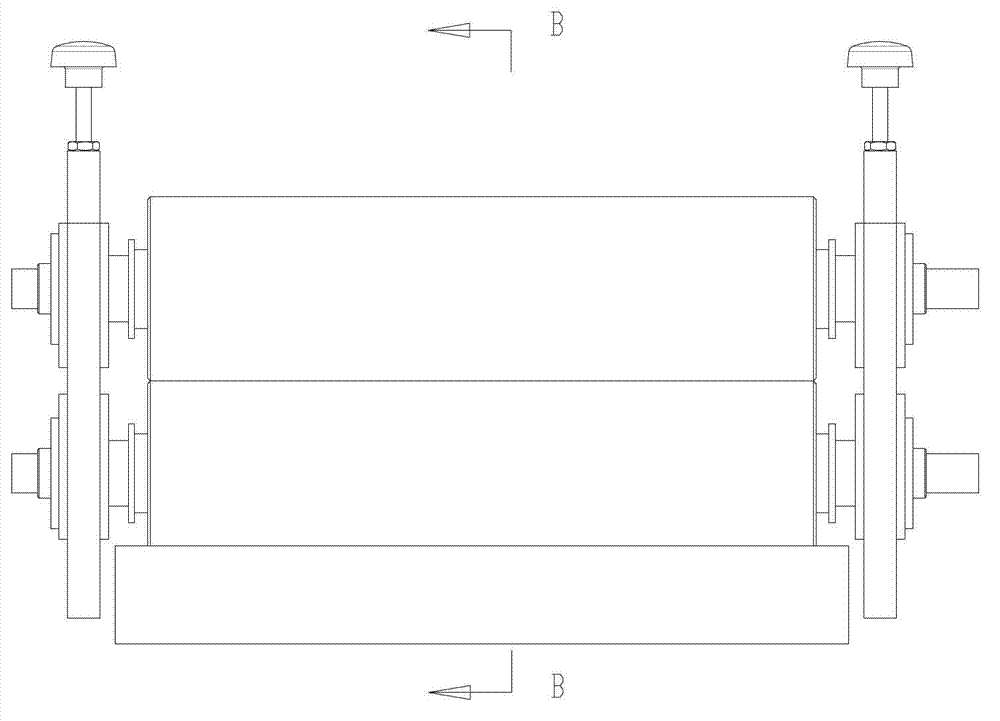

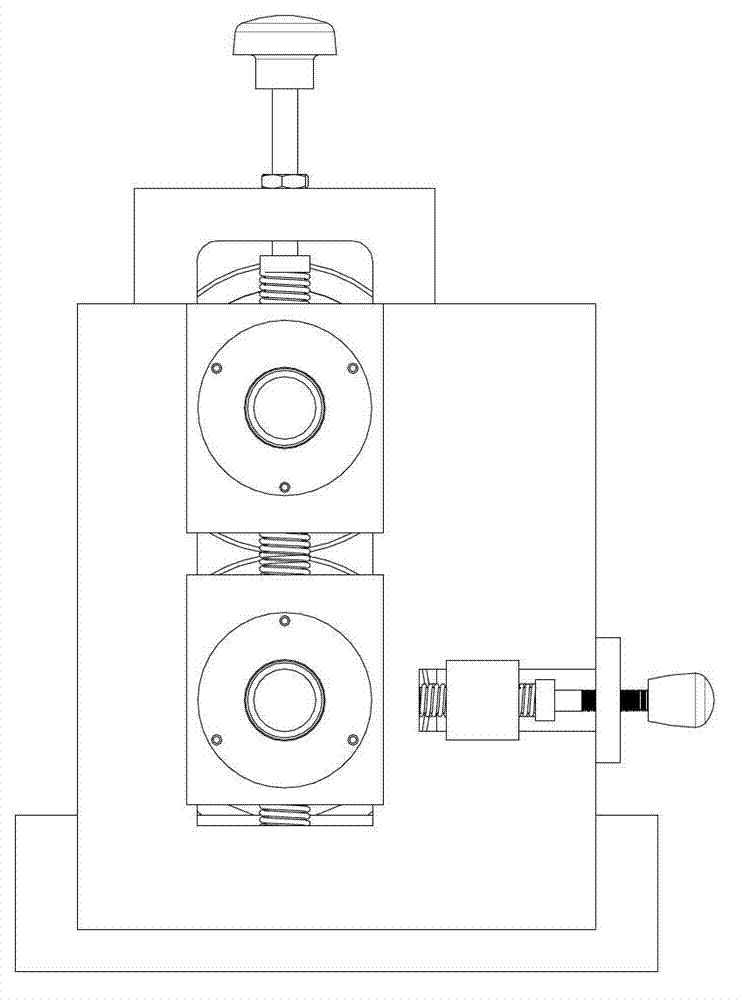

[0021] An automatic double-sided oiler, such as Figure 1-3 As shown, it includes an oiling roller mechanism 1, an oil film regulating mechanism 2, an oil tank mechanism 3, and matching control mechanisms. The oil coating roller mechanism 1 includes an oil coating roller, the oil coating roller is placed in the oil tank 31 of the oil tank mechanism 3, and an oil film adjustment device for adjusting the thickness of the oil film, etc. is provided on the oil coating surface of the oil coating roller. Institution 2. Wherein said oiling roller can be made up of first oiling roller 12 and second oiling roller 13, wherein said second oiling roller 13 places in the oil groove, and said first oiling roller 12 and second oiling roller The roller surface of the oil roller 13 is tangential in the vertical direction and has a certain pressing force bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com