Atomized fall type coal paste preprocessor

A pre-conditioner, drop-type technology, applied in chemical instruments and methods, chemical/physical processes, fluid mixers, etc., can solve the loss of coarse coal particles, poor effect, and contact time between floating coal slurry and flotation agent Shortage and other problems, to achieve the effect of avoiding impurity blockage and good process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

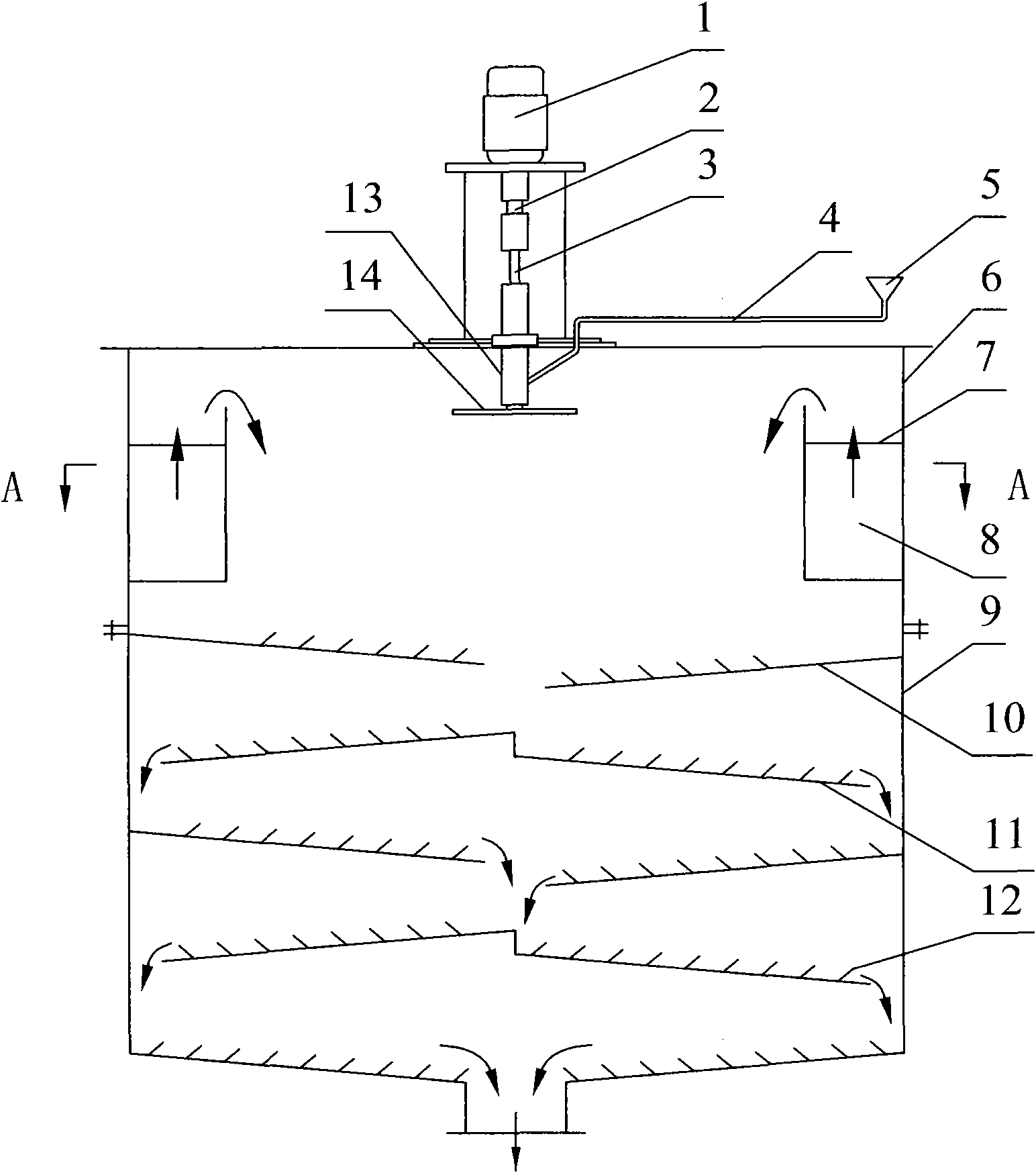

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

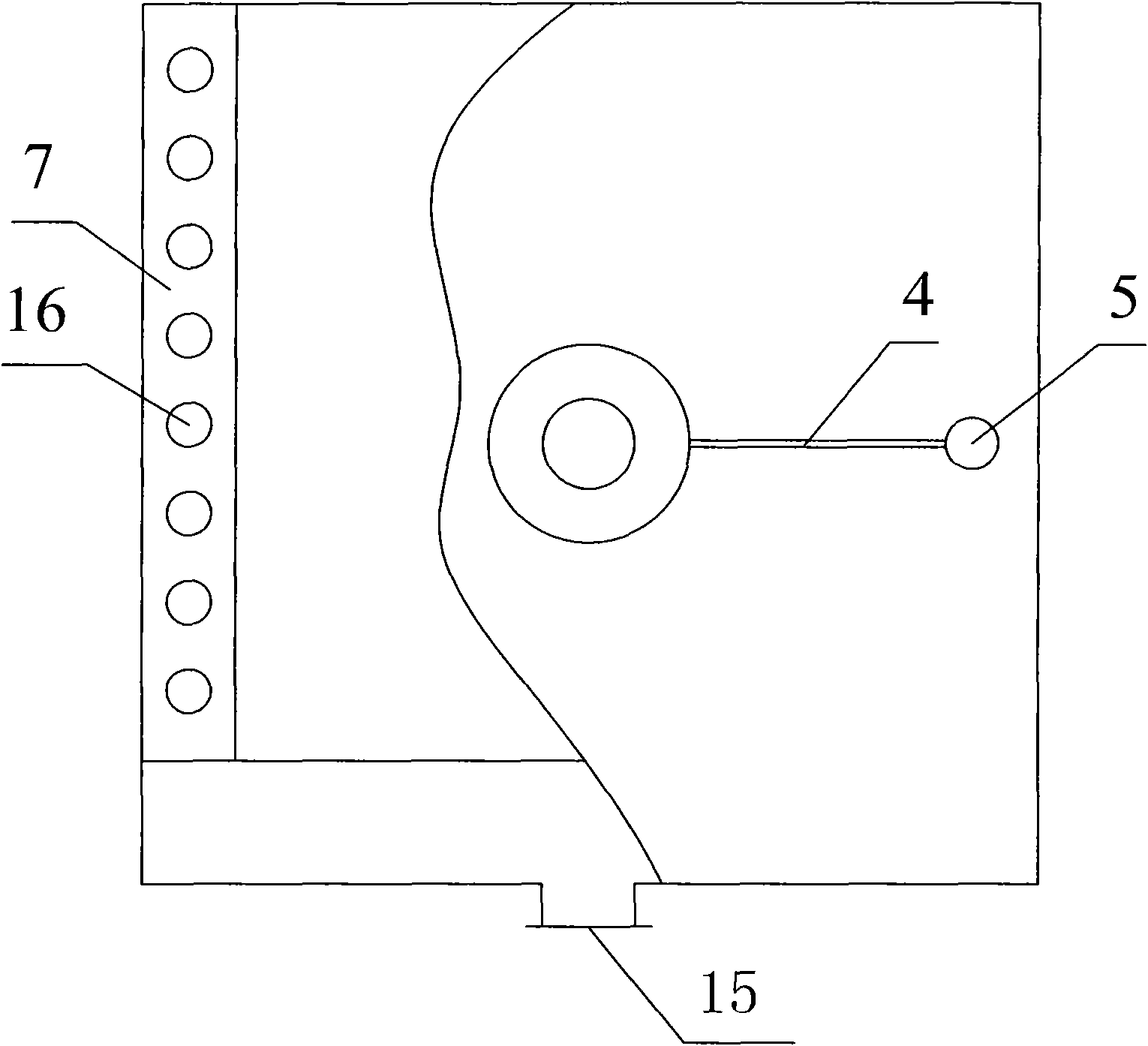

[0018] See attached Figure 1-4 , In the present embodiment, the drop box of this atomized drop coal slurry preprocessor is a box with a square section, and an atomization device is arranged on the top of the drop box. Both sides of the lower box body 9 of the drop box are welded with slide plates, and the vertical shaft 3 of the fogging disc 14 in the atomizing device is connected with the output shaft of the top motor 1 through a flexible coupling 2 .

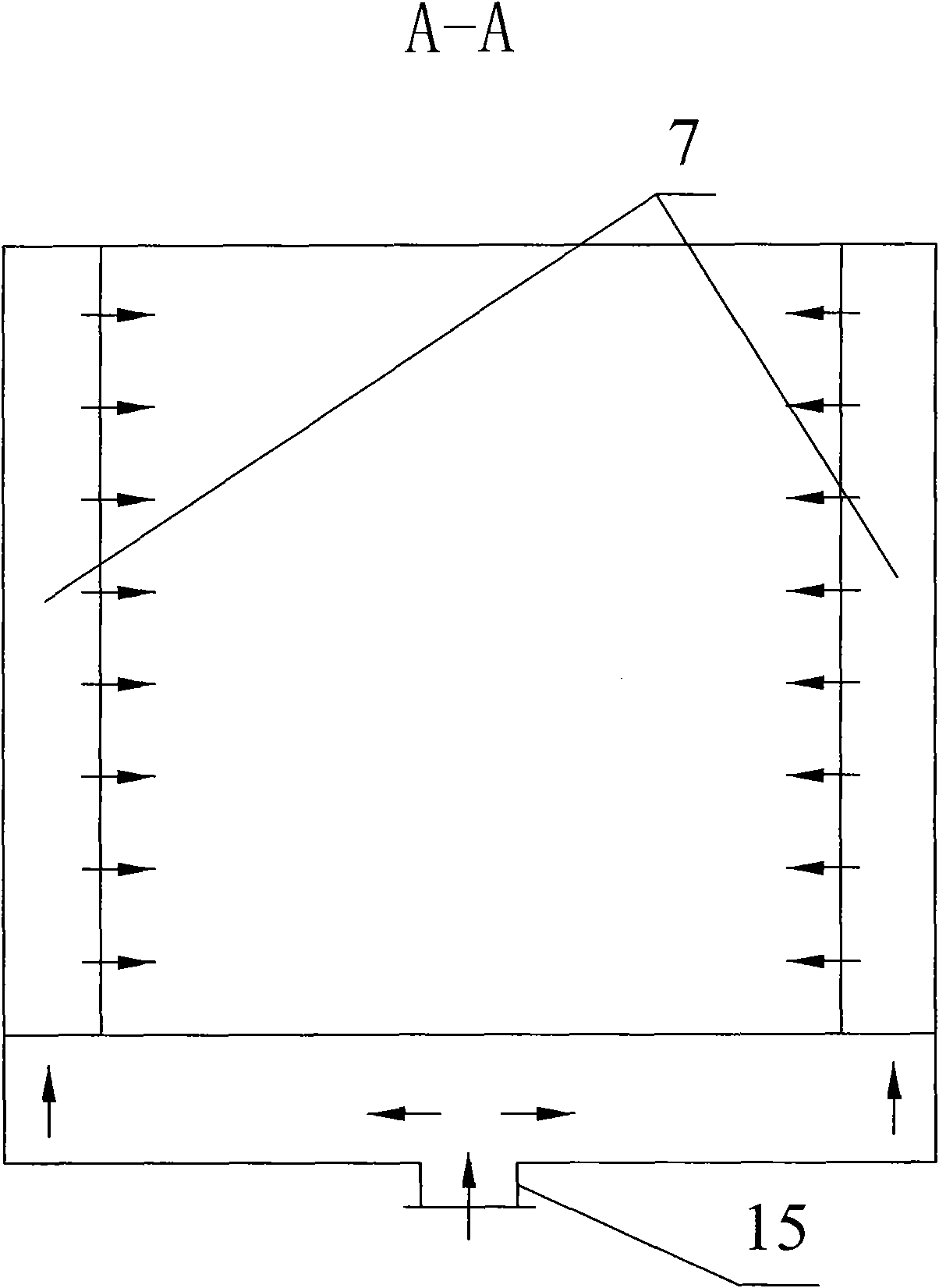

[0019] The upper box body 6 of the drop box is the working area for feeding and flotation agent atomization. The upper box body 6 is provided with a central feed pipe 15, and overflow tanks 8 are arranged on both sides of the interior, and the inside of the overflow tank 8 is respectively A partition 7 with perforations 16 is provided, and eight perforations 16 with a diameter of 100 mm are evenly d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com